Fishing seven-star buoy or space bean lead wire handle structure and process

A space bean and lead wire technology is applied in fishing lines, fishing accessories, fishing and other directions, which can solve the problems of non-recyclability, waste of resources and can only be discarded, and achieve the effect of convenient production process and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below in conjunction with the accompanying drawings.

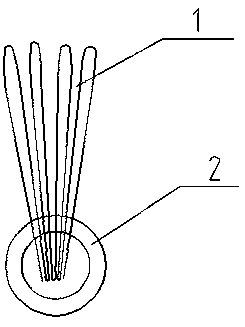

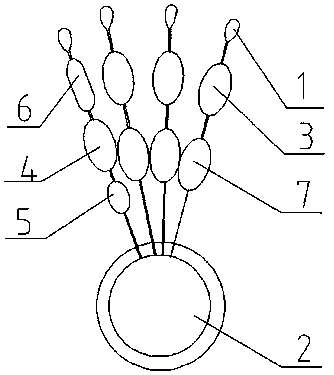

[0015] Fishing seven-star float or space bean lead handle structure, including lead 1 and handle 2, one end of lead 1 and handle 2 after one-time injection molding is integrated, lead 1 is worn with seven-star float 3 or space bean 6 or locking bean 5 or Counterweight pendant 4 or anti-winding bean 7.

[0016] The structure and process of fishing seven-star float or space bean lead handle include the following steps:

[0017] 1) Wind the prepared high-temperature-resistant nylon wire into the required number of turns, and combine several wires into lead wire 1,

[0018] 2) Put part of one end of the lead wire 1 into the injection mold, inject engineering plastics into the injection mold, and one-time injection molding synthesis becomes the lead wire 1 and the handle 2,

[0019] 3) Wear seven-star float 3 or space bean 6 or locking bean 5 or counterweight pe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com