Processing method of tippy tea

A processing method, the technology of Maojian tea, which is applied in the field of tea processing, can solve the problems of low yield, high price, and unsatisfactory industrial products of Duyun Maojian tea, and achieve the preservation of taste and nutrients, high yield, and complete and uniform buds and leaves Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

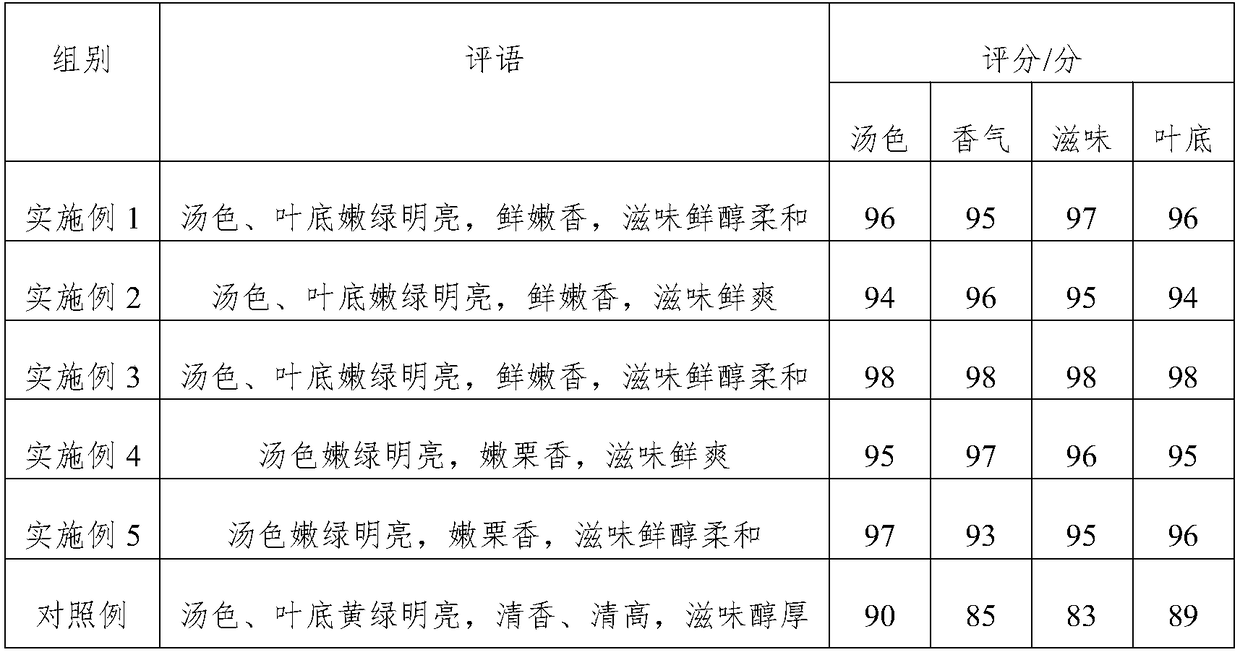

Examples

Embodiment 1

[0036] A processing method of Maojian tea, comprising the following steps:

[0037] (1) Picking: Classify the picked fresh tea leaves according to different grades and different picking times, remove broken leaves and other foreign objects, and store them separately;

[0038] (2) green spreading: the fresh tea leaves picked back will be conveyed by a green spreading machine, and placed on a ventilated and clean bamboo dustpan for green spreading; 5cm, and the time is 5h; the water content of the tea leaves after the green spreading process is 80%; the conveying speed of the green spreading machine is 0.1m / min;

[0039] (3) Finishing: place the green tea leaves on the conveyor belt, control the temperature and rotating speed of the roller fixing machine, and then send the tea leaves into the roller fixing machine for finishing; the inlet temperature of the roller fixing machine is controlled at 100°C and the outlet temperature The temperature is controlled at 100°C, the time f...

Embodiment 2

[0050] A processing method of Maojian tea, comprising the following steps:

[0051] (1) Picking: Classify the picked fresh tea leaves according to different grades and different picking times, remove broken leaves and other foreign objects, and store them separately;

[0052] (2) green spreading: the fresh tea leaves picked back will be conveyed by a green spreading machine, and placed on a ventilated and clean bamboo dustpan for green spreading; 10cm, and the time is 8h; the water content of the tea leaves after the green spreading process is 85%; the conveying speed of the green spreading machine is 0.5m / min;

[0053] (3) Finishing: place the green tea leaves on the conveyor belt, control the temperature and rotating speed of the roller fixing machine, and then send the tea leaves into the roller fixing machine for finishing; the inlet temperature of the roller fixing machine is controlled at 130°C and the outlet temperature The temperature is controlled at 120°C, the time ...

Embodiment 3

[0064] A processing method of Maojian tea, comprising the following steps:

[0065] (1) Picking: Classify the picked fresh tea leaves according to different grades and different picking times, remove broken leaves and other foreign objects, and store them separately;

[0066] (2) green spreading: the fresh tea leaves picked back will be conveyed by a green spreading machine, and placed on a ventilated and clean bamboo dustpan for green spreading; 8cm, the time is 6.5h; the water content of the tealeaves after the spreading process is 83%; the conveying speed of the spreading machine is 0.3m / min;

[0067] (3) Finishing: place the green tea leaves on the conveyor belt, control the temperature and rotating speed of the roller fixing machine, and then send the tea leaves into the roller fixing machine for finishing; the inlet temperature of the roller fixing machine is controlled at 115°C and the outlet temperature The temperature is controlled at 110°C, the time for tea leaves t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com