Continuous suture device used for suture operation under laparoscope

A laparoscope and stapler technology, applied in the field of medical devices, can solve the problems of long suture time, unfavorable patient recovery, time-consuming and labor-intensive, etc., and achieve the effects of good suture effect, shortened operation cycle, and convenient operation and use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

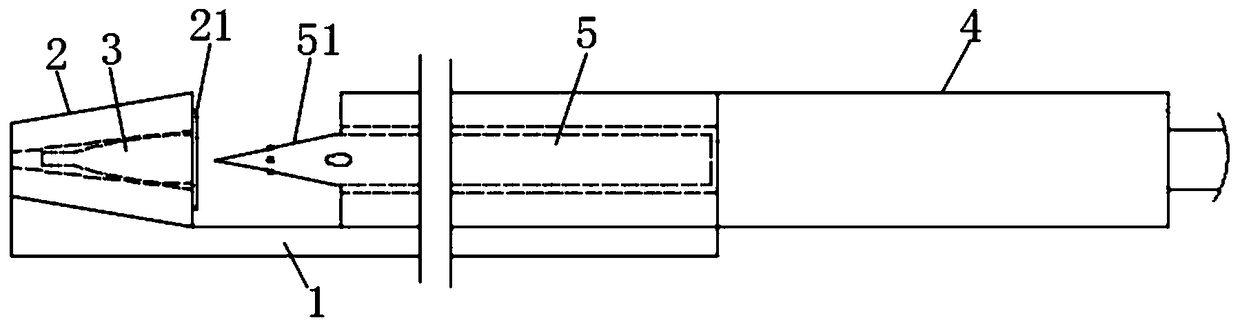

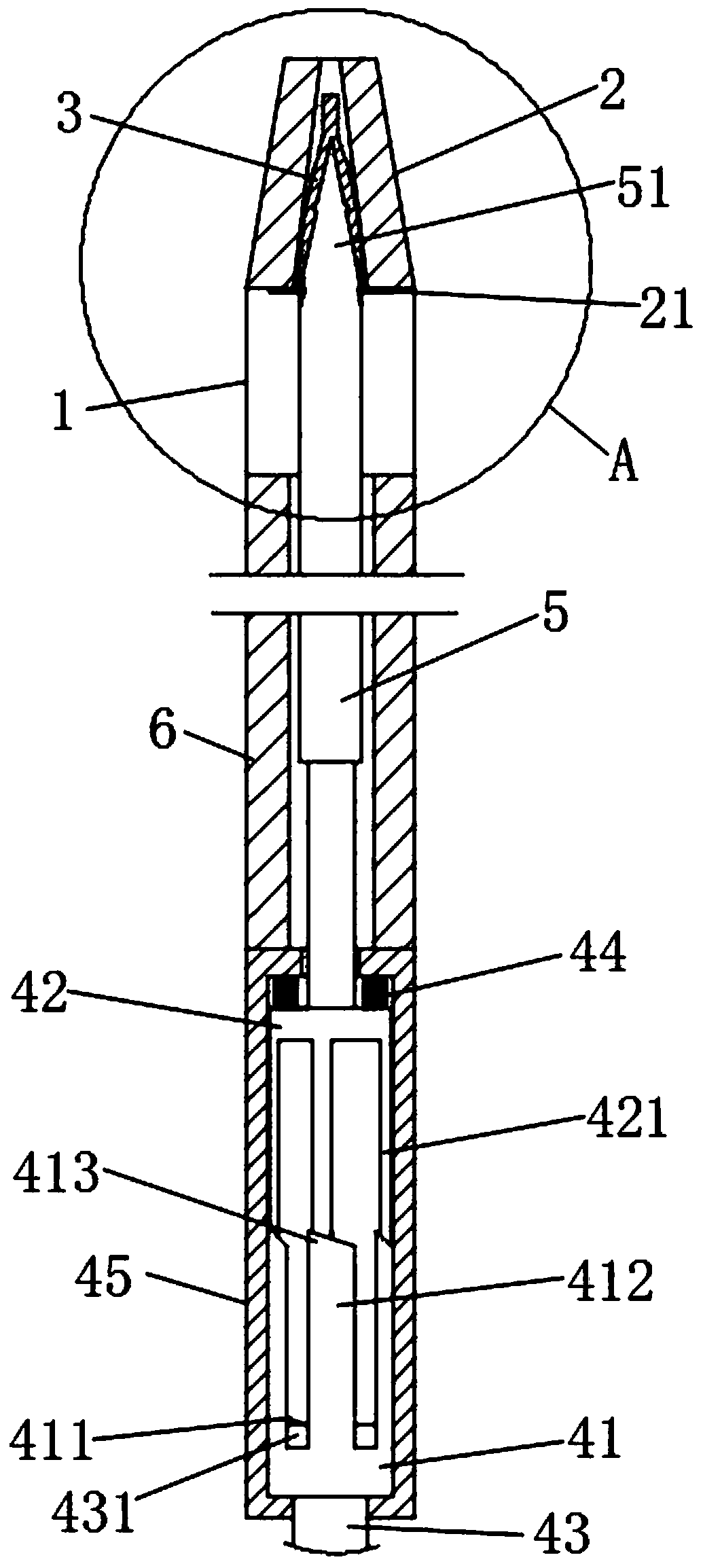

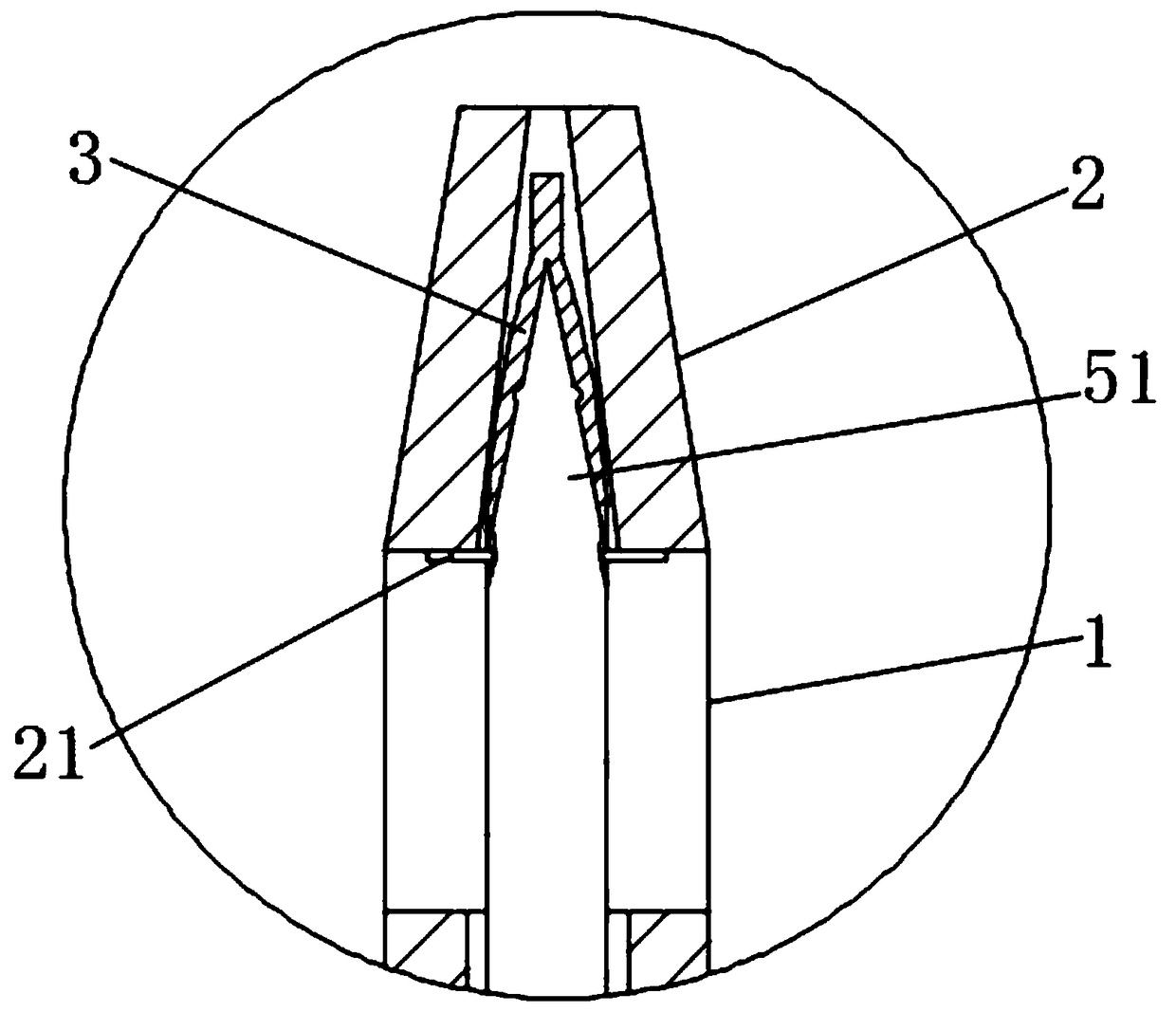

[0039] Example: such as Figures 1 to 4 As shown, the continuous stapler for laparoscopic suturing in this embodiment includes a bobbin seat 2, a bobbin 3, a needle cylinder 6, a suture needle 5 and a driving mechanism 4;

[0040] The above-mentioned needle cylinder 6 is a cylinder with both ends open, and the above-mentioned bobbin seat 2 is arranged at one end of the above-mentioned needle cylinder 6 at intervals, and the two are connected to each other through the connecting piece 1;

[0041] A suture needle 5 is arranged in the above-mentioned needle cylinder 6 along its axial direction, the needle head 51 of the above-mentioned suture needle 5 is tapered, and protrudes from one end of the above-mentioned needle cylinder 6 close to the above-mentioned bobbin seat 2;

[0042] The above-mentioned bobbin seat 2 is penetrated with a bobbin accommodating cavity extending to both ends thereof and matched with the above-mentioned bobbin 3, the above-mentioned bobbin 3 is arranged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com