Construction garbage crushing device

A technology of crushing device and construction waste, applied in grain processing and other directions, can solve problems such as erosion, reduce soil quality, affect production, etc., achieve good vibration and vibration isolation, improve consistency, and run smoothly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

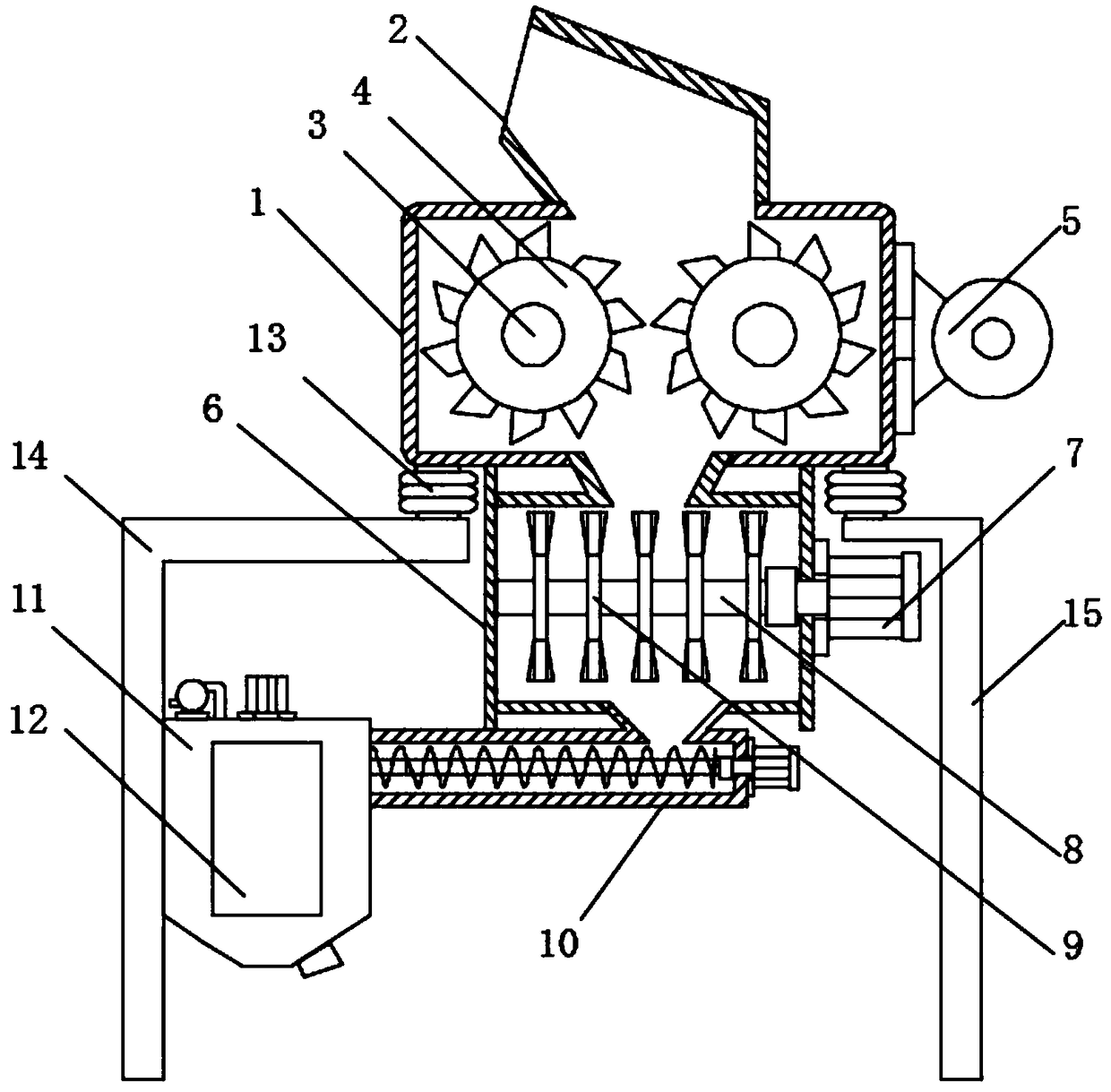

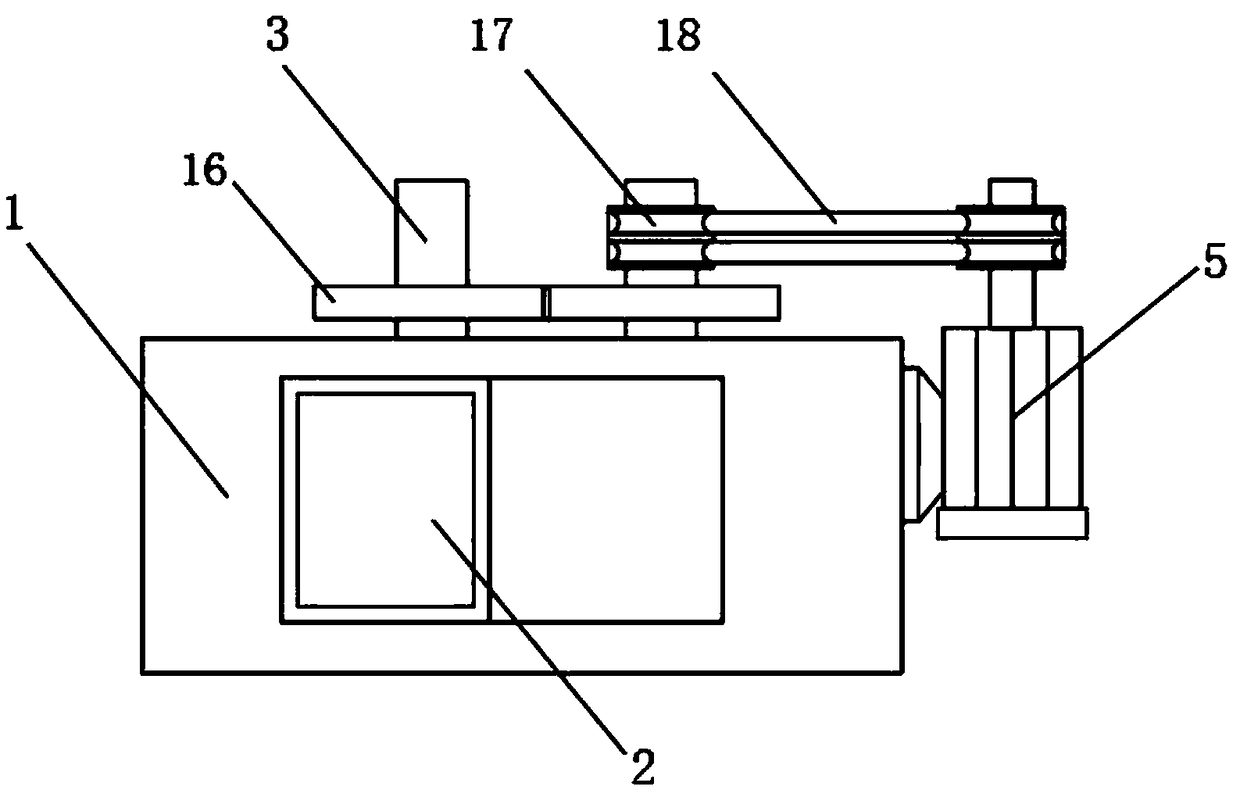

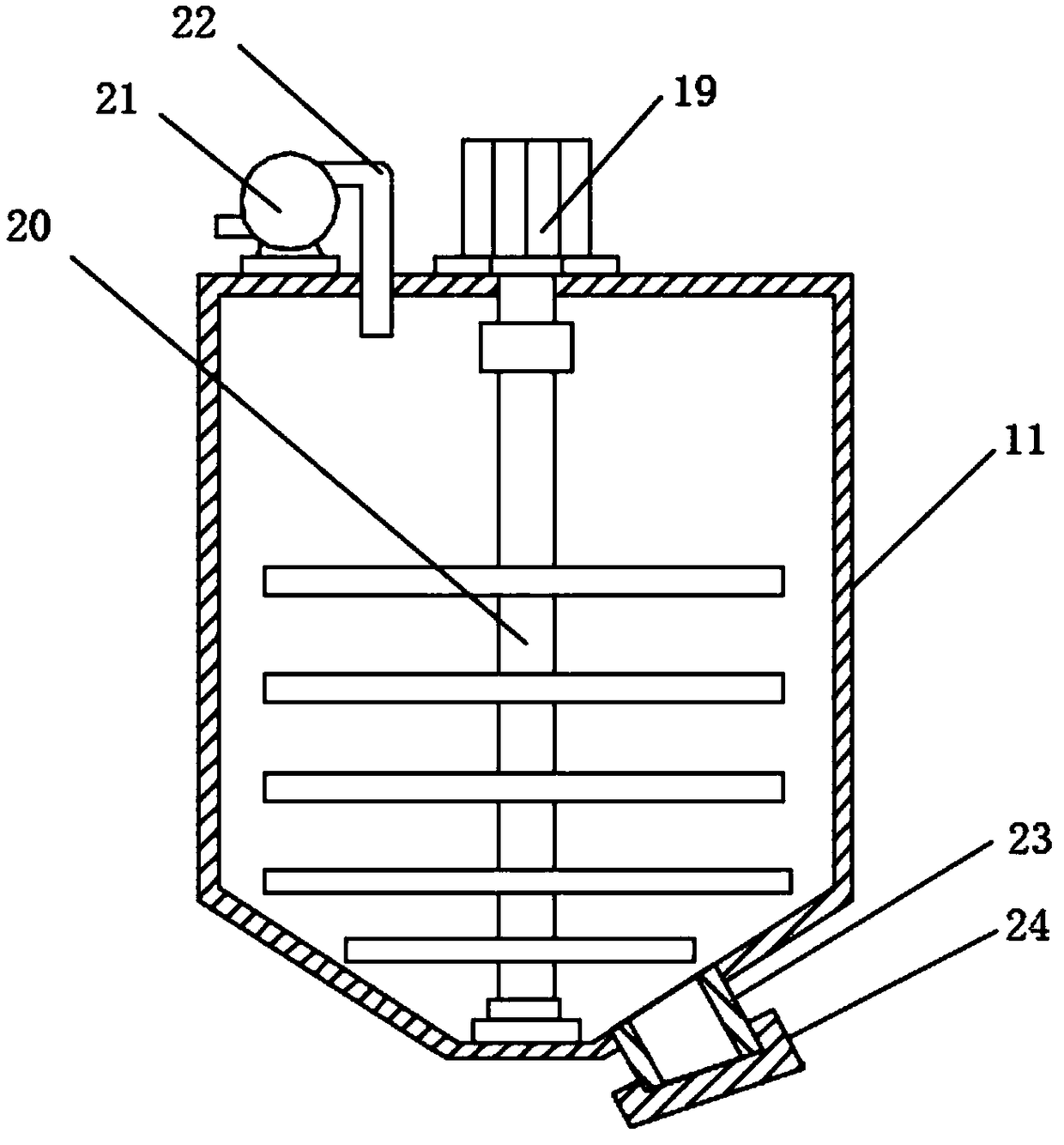

[0022] from Figure 1-3 It can be seen that a construction waste crushing device in this embodiment includes No. 1 crushing box 1 and No. 2 crushing box 6, No. 2 crushing box 6 is fixedly welded on the bottom of No. 1 crushing box 1, and the bottom of No. 1 crushing box 1 The top is welded with a feed cover 2, the inner cavity of the No. 1 crushing box 1 is horizontally installed with a No. 1 rotating shaft 3, the outer ring of the No. 1 rotating shaft 3 is fitted with a crushing cylinder 4, and a No. 1 motor 5 is installed on the right side of the No. 1 crushing box 1 , No. two motors 7 are installed on the right side of No. two crushing case 6, and the output end of No. two motors 7 runs through No. two crushing cases 6 and is connected with No. two rotating shafts 8.

[0023] The outer wall of the No. 2 rotating shaft 8 is evenly socketed with crushing discs 9, and the crushing discs 9 are arranged at equidistant intervals of the No. 2 rotating shaft 8 to enhance the crushi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com