Laser cutting speed planning method, device, storage medium and computer equipment

A technology of speed planning and laser cutting, which is applied to laser welding equipment, welding equipment, metal processing equipment, etc., and can solve the problems of increasing laser cutting time and low laser cutting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

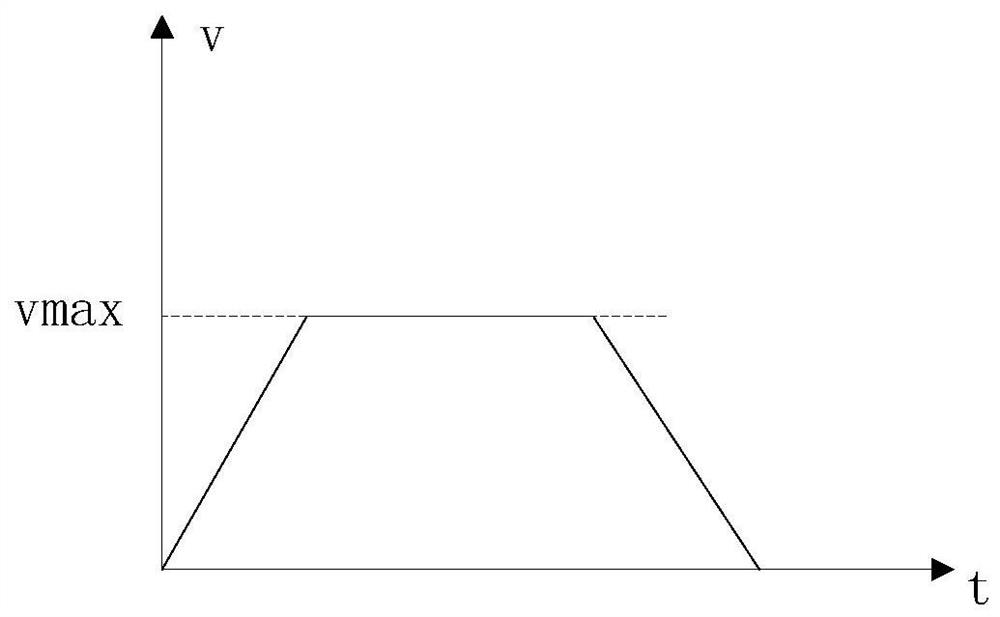

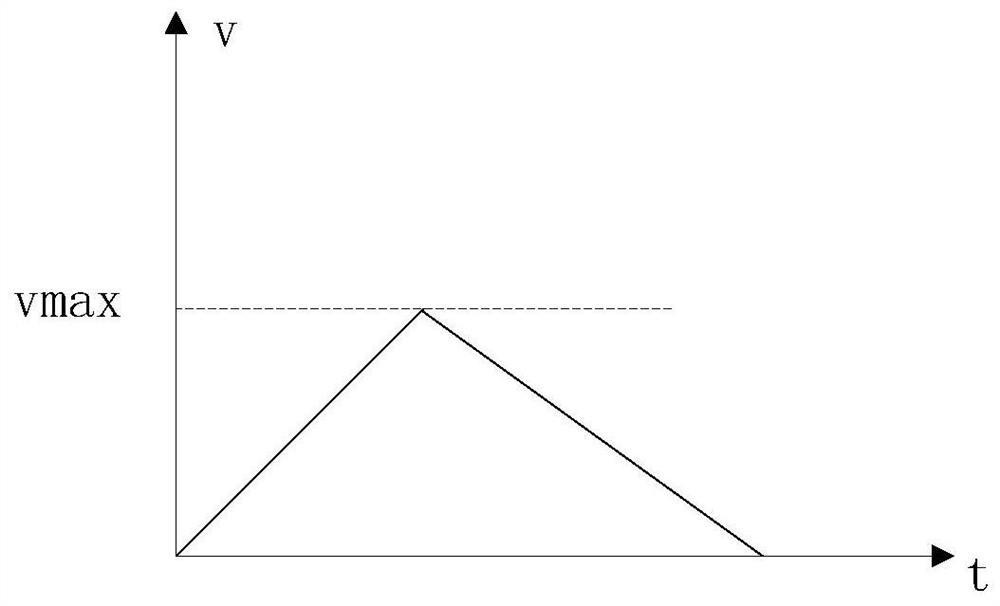

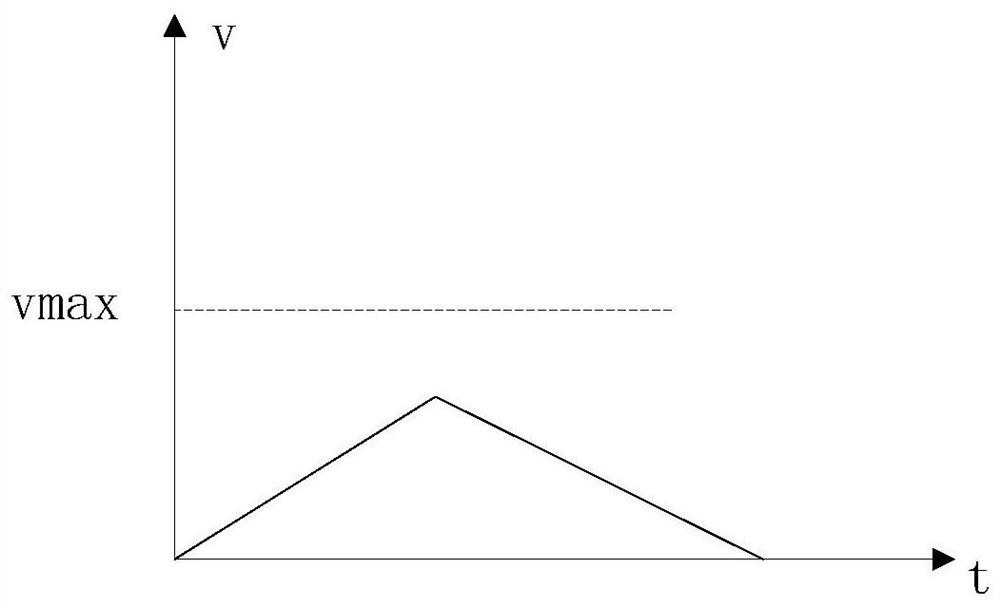

[0030] In one embodiment, such as figure 2 As shown, a laser cutting speed planning method is provided, which includes the following steps:

[0031] Step S100, acquiring information of a current first cutting stroke in a cutting track to be processed, and information of a current second cutting stroke connected with the current first cutting stroke.

[0032] In this step, the cutting track to be processed refers to the track of laser cutting, which is generally composed of straight lines and / or arcs, and a straight line or arc represents a cutting stroke of a corresponding shape. Specifically, such as image 3 As shown, a schematic diagram of a laser cutting cutting track to be processed is provided, and the cutting track to be processed includes a cutting stroke L i , L i+1 and L i+2 . When performing speed planning, it is necessary to calculate the corner speed of the connection point of two adjacent cutting strokes. When calculating the corner speed of a certain conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com