Automatic loading and unloading device of numerical control lathe

An automatic loading and unloading, CNC lathe technology, applied in the field of parts manufacturing and processing, can solve the problems of high cost and later maintenance costs, complicated motion control programs, complex mechanical structures, etc., to reduce labor intensity and labor time, maintenance and maintenance. Simple, easy-to-maintain effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

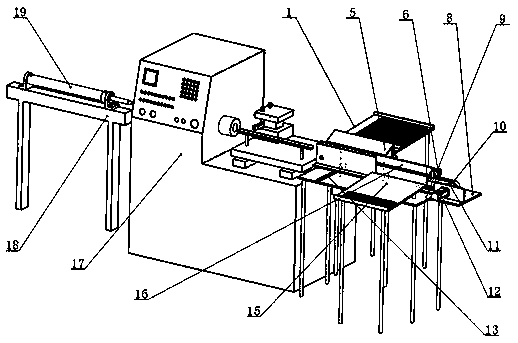

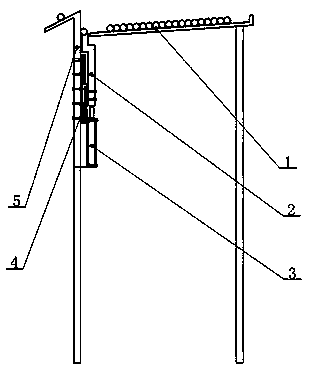

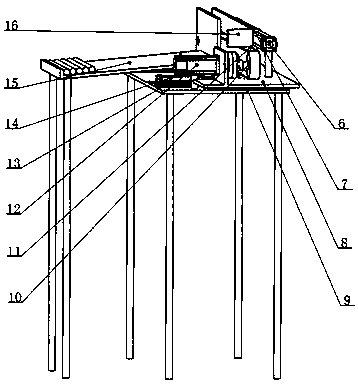

[0027] Embodiment 1: as Figure 1-4 As shown, an automatic loading and unloading device for a CNC lathe, including a feeding device, a conversion transmission device, and a feeding device;

[0028] The feeding device includes a feeding cylinder 6, a feeding bracket 7, and a feeding rack 9;

[0029] The cylinder block of described feeding cylinder 6 is connected and fixed on the conversion pallet 8 on the feeding frame 9, and the feeding frame 9 is slidably connected with the conversion pallet 8, and the push rod of the feeding cylinder 6 is used to push the to-be Processing the workpiece; the feeding bracket 7 is used for receiving materials;

[0030] The conversion transmission device includes a conversion pallet 8, a driving wheel 10, a conveyor belt 11, a servo motor 12, a conversion guide rail 13, a conversion cylinder 14, and a driven wheel;

[0031] The servo motor 12 is fixed on the conversion pallet 8, the driving wheel 10 is driven by the servo motor 12, the conveyo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com