Automatic tool changing mechanism of automatic cutting bed

A technology of automatic tool change and cutting bed, applied in the field of cutting bed, can solve the problems of inconvenient operation and reduce work efficiency, and achieve the effect of saving working time, saving working time and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

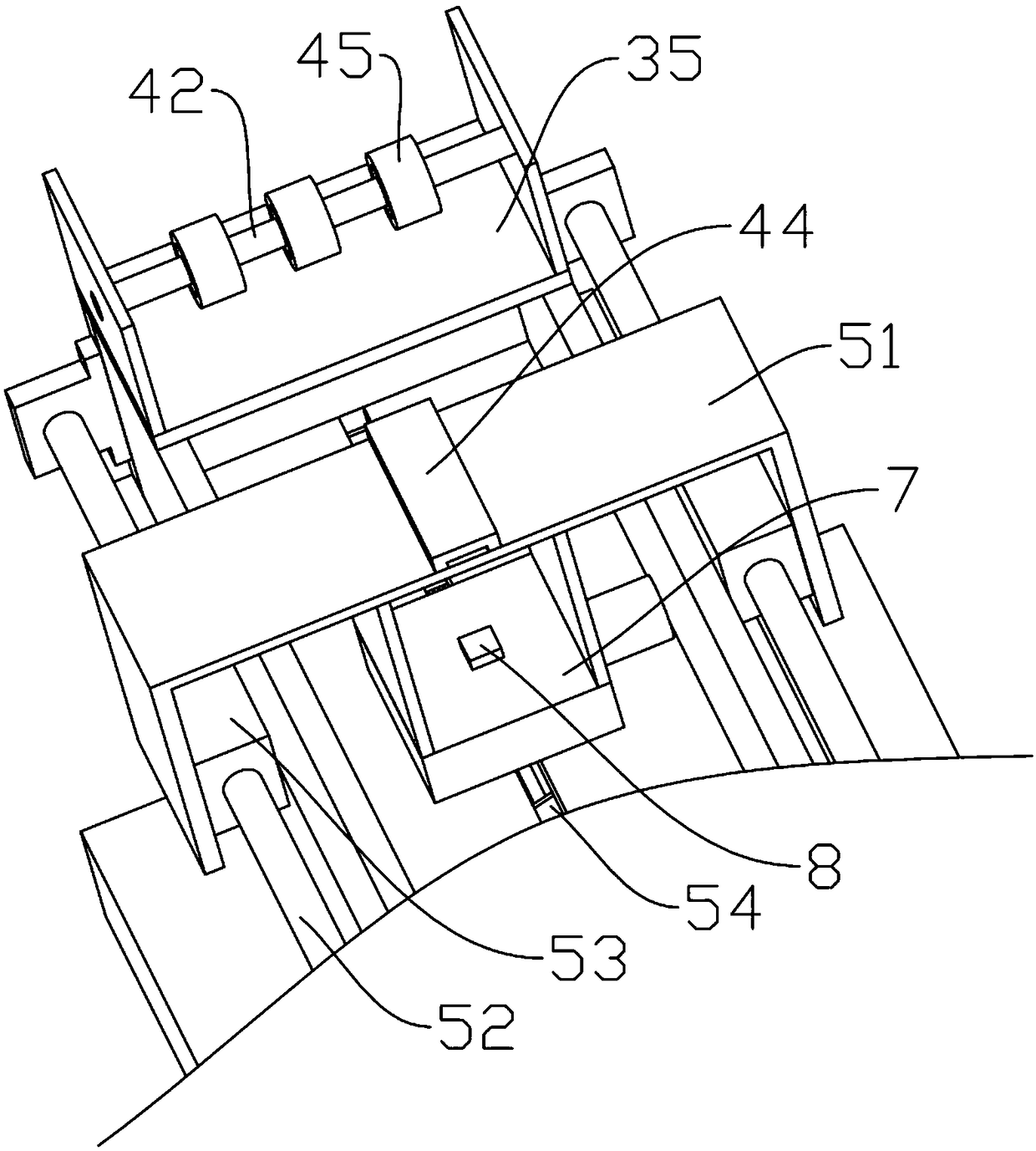

[0056] Compared with the difference from Example 1, as Figure 6-Figure 8 As shown, the automatic tool change mechanism also includes a die magazine 11, the die magazine 11 is arranged on both sides of the body 1, a loading plate 12 is arranged on the die magazine 11, and guide sleeves are arranged on the corners of the die magazine 11 , The loading plate 12 is provided with a guide rod that runs through the guide sleeve. A number of stamping dies 37 are placed on the loading plate 12, and the body 1 is connected with a pusher 13 that drives the die storehouse 11 to move. The pusher 13 is set as the first driving cylinder, and the pusher 13 is electrically connected to the main control system.

[0057] A reference pin 14 that penetrates the loading plate 12 and the limit hole 102 is slidably provided in the knife mold library 11, and the loading plate 12 is provided with an accommodation block, and the accommodation block is provided with an accommodation groove 15, and the ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com