Water gap rotary cutting jig

A nozzle and fixture technology, applied in the field of nozzle rotary cutting fixtures, can solve the problems of poor safety, long processing cycle, product damage, etc., and achieve the effect of efficient and thorough rotary cutting, not easy to leak, and stable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

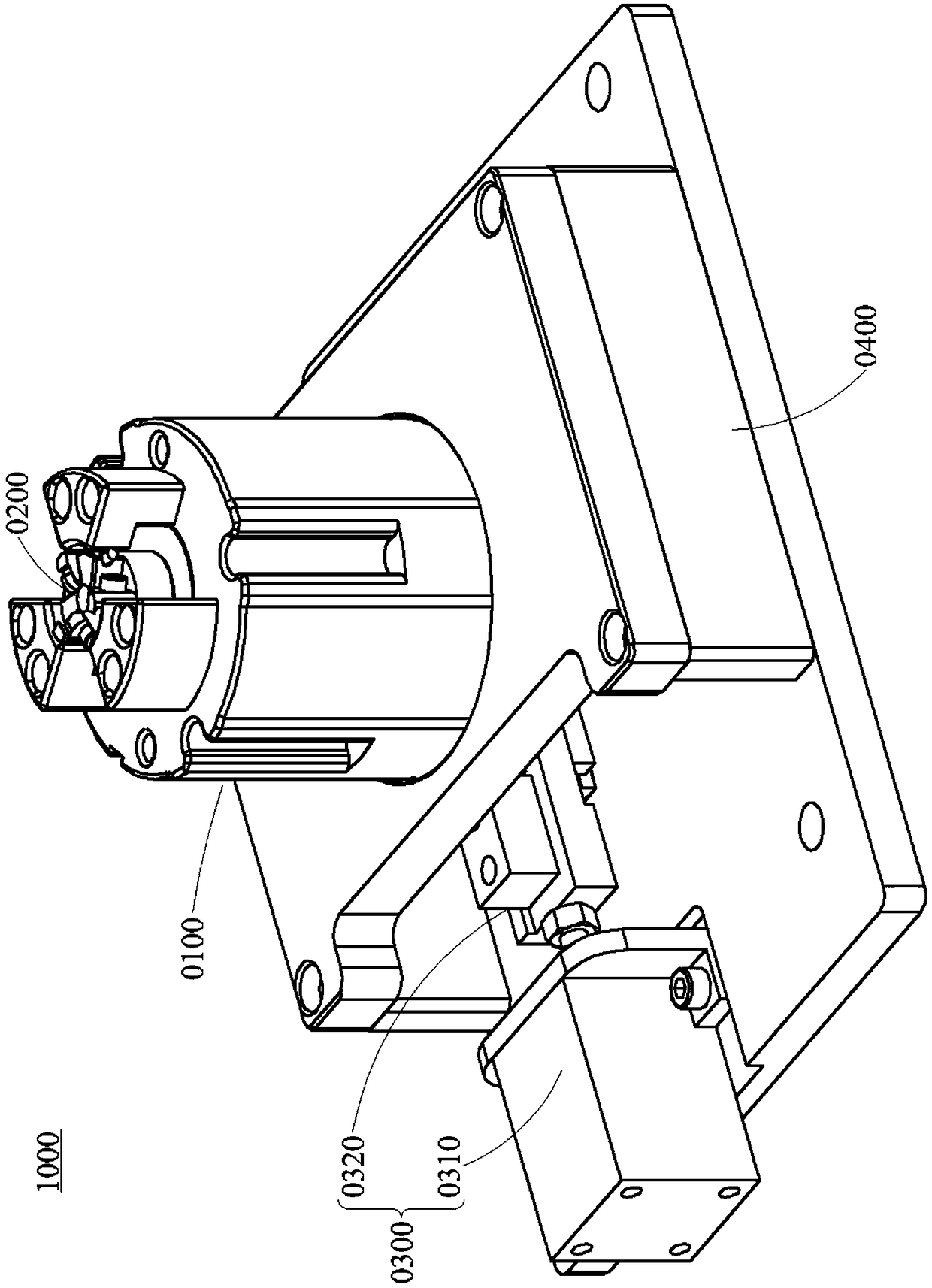

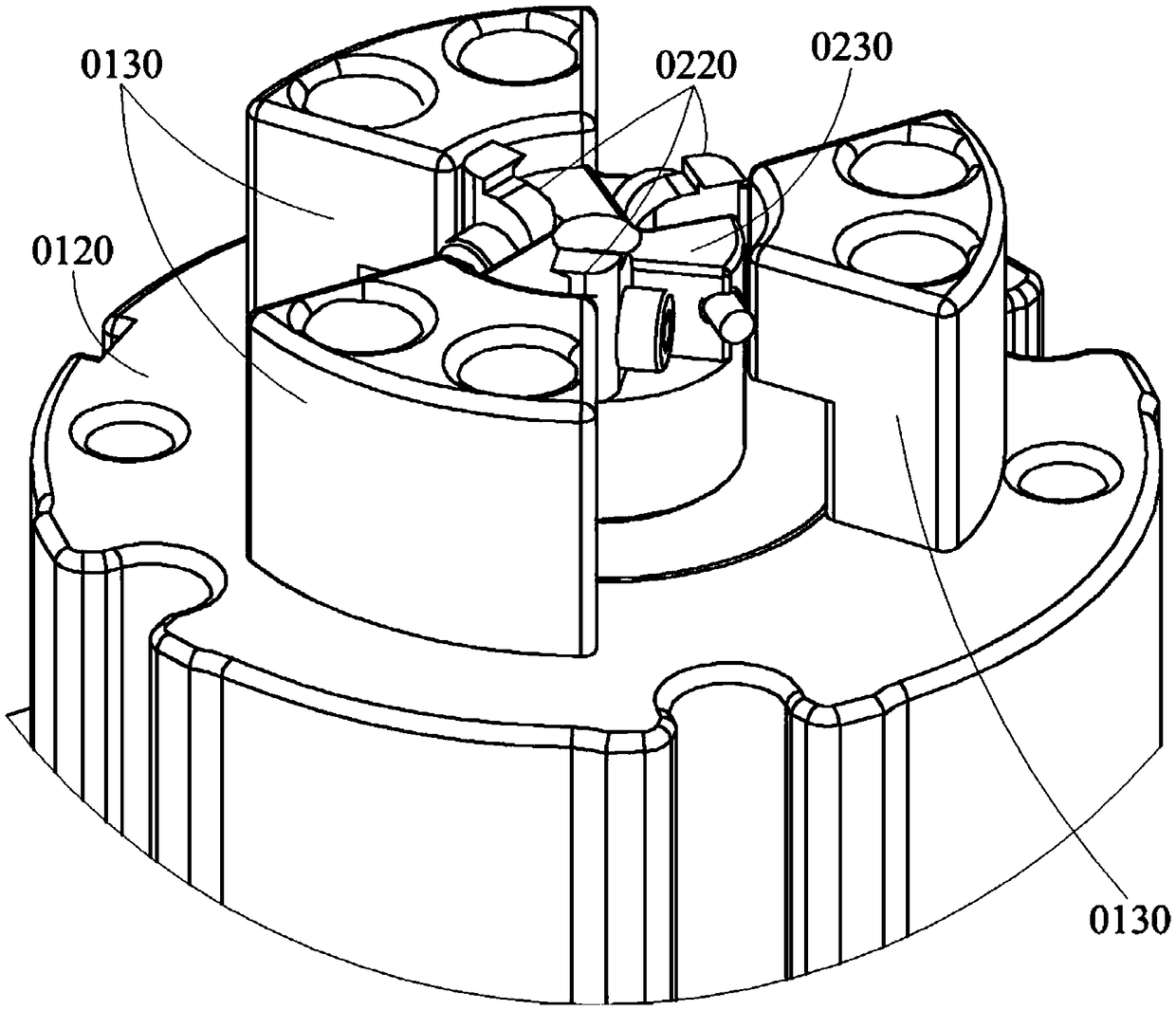

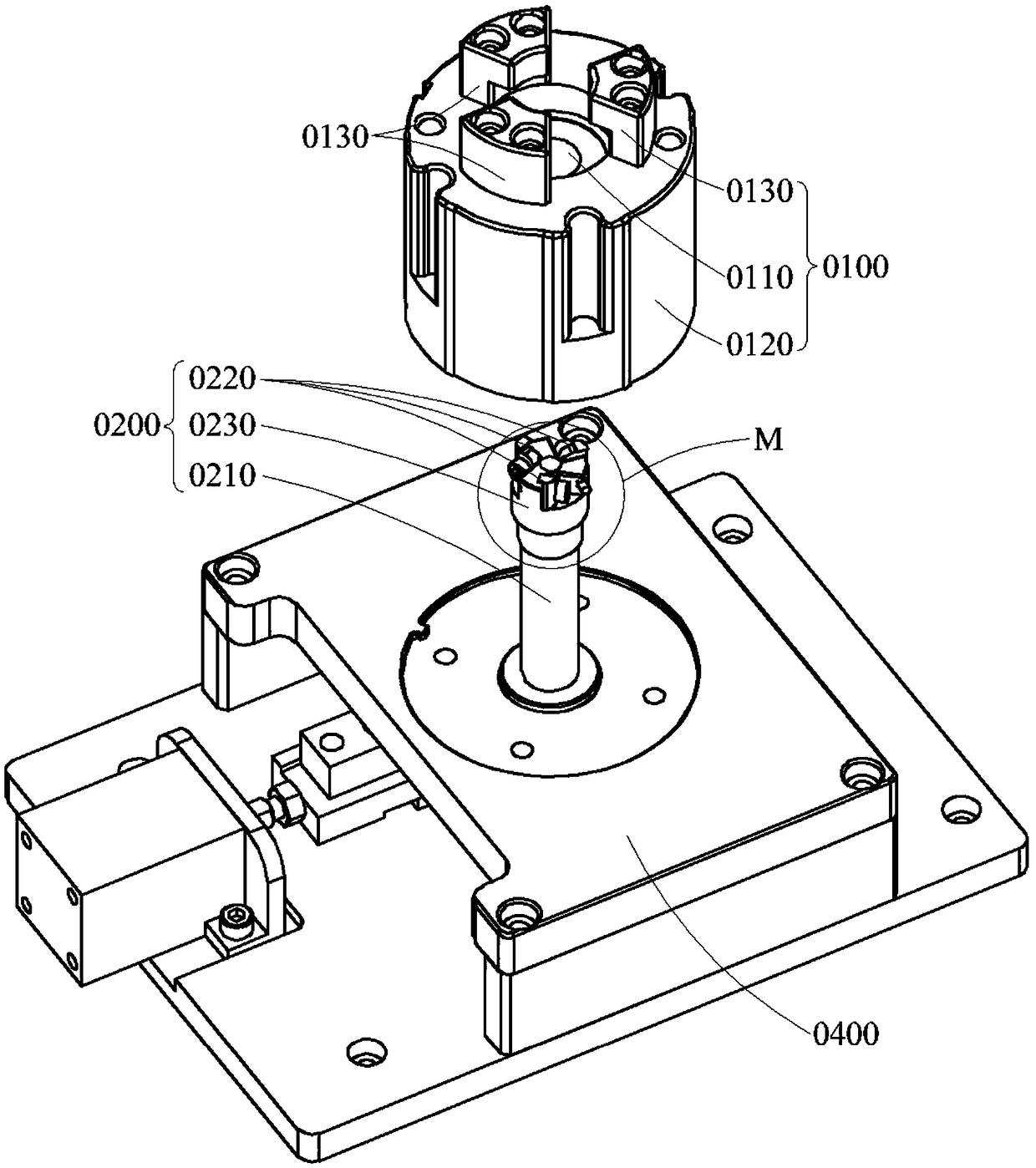

[0038] Please refer to Figure 1~6 , this embodiment discloses a nozzle rotary cutting fixture 1000, the nozzle rotary cutting fixture 1000 includes a positioning bottom mold 0100, a spindle unit 0200 and a driving unit 0300, which are used to achieve safety, reliability, simple operation, excellent processing efficiency and quality Nozzle rotary cutting.

[0039] First of all, the product P to be processed is a blank removed from the injection molding machine after injection molding, and the nozzle has not been cleaned. It can be understood that the product P to be processed includes the product body P(a) and the nozzle P(b), and the product body P(a) and the nozzle P(b) are still connected. The shape of the product body P(a) is determined according to actual product requirements. Exemplarily, the product body P(a) is a cylindrical plastic shell. Correspondingly, the nozzle P(b) overlaps the opening of the end of the cylindrical plastic housing (for example, the center of t...

Embodiment 2

[0060] Please refer to Figure 8-9 , this embodiment discloses a nozzle rotary cutting device U, the nozzle rotary cutting device U includes a worktable 2000 and an electric control system 3000, and the nozzle rotary cutting fixture 1000 and the top tightening unit introduced in Embodiment 1 are set on the workbench 2000 4000, realizing fast and reliable nozzle rotary cutting.

[0061] Workbench 2000 provides the main operating place for nozzle rotary cutting, and provides the installation basis for other components. Exemplarily, the workbench 2000 has a work chamber 2100 with one side open, providing a safe and reliable place for operation. The nozzle rotary cutting jig 1000 and the clamping unit 4000 are both arranged in the working chamber 2100 to obtain the safety protection of the working chamber 2100 . The working chamber 2100 is well sealed to avoid accidents caused by accidental touches, and is also conducive to ensuring a good working environment for the nozzle rota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com