Automatic tray receiving and transmitting system

An automatic sending and receiving, palletizing technology, applied in the stacking of objects, de-stacking of objects, conveyors, etc., can solve the problems of not substantially satisfying automatic production, low efficiency, heavy weight, etc., and achieve flexible pallet loading methods. , Simple structure and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

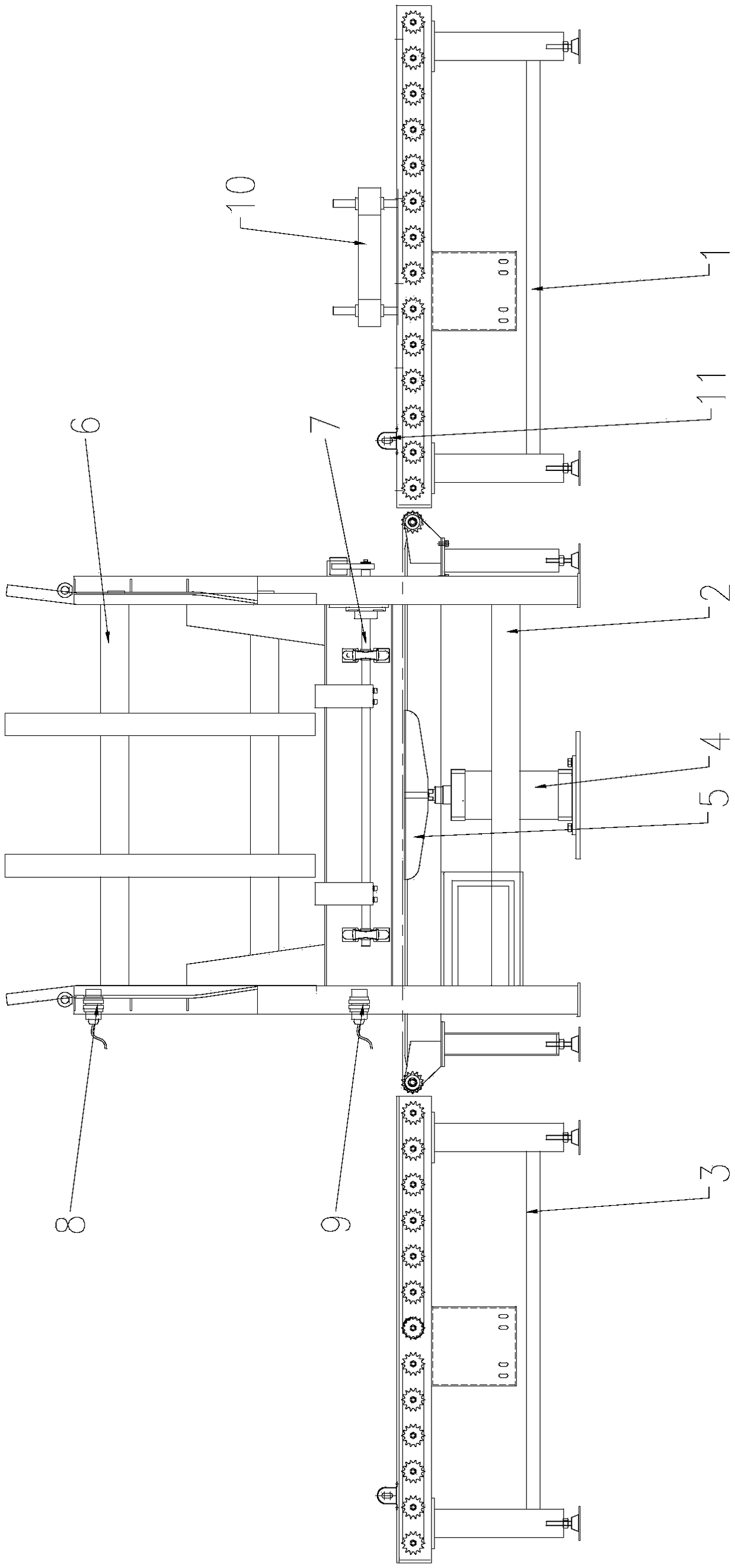

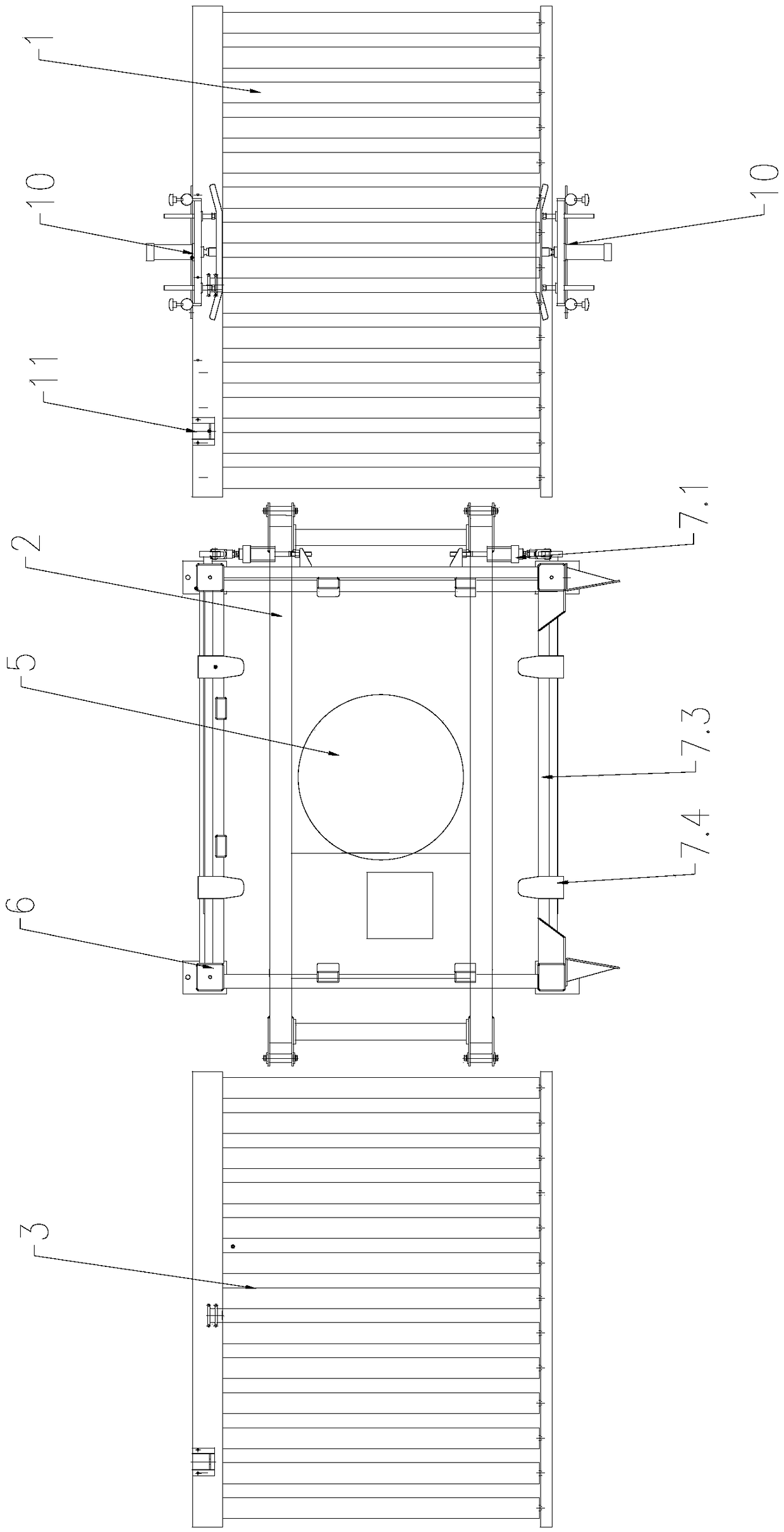

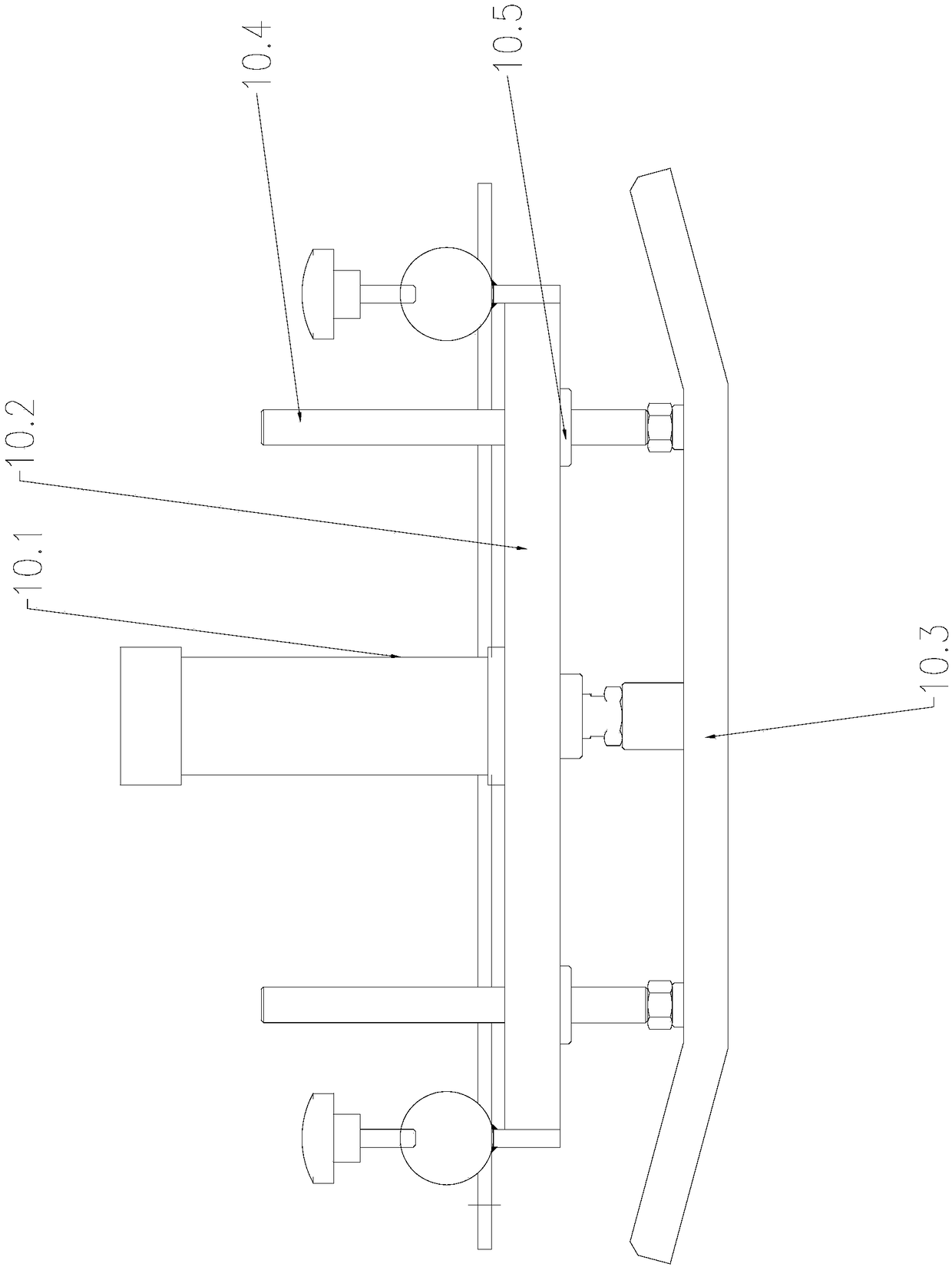

[0018] Such as Figure 1~2 As shown, the present invention mainly includes an input roller conveyor 1 , a chain conveyor 2 , an output roller conveyor 3 , a lifting mechanism, a tray storehouse 6 and a plate assembly 7 .

[0019] The input roller conveyor 1, the chain conveyor 2 and the output roller conveyor 3 are arranged in sequence according to a straight line, and the tray is conveyed along the direction of the input roller conveyor 1, the chain conveyor 2 and the output roller conveyor 3. There is a lifting mechanism directly under the chain conveyor 2. The lifting mechanism can hold up the pallets on the chain conveyor 2 for storage operation. The left and right sides of the chain conveyor 2 are provided with pallet storage 6, and the pallet storage 6 is provided with a plugboard assembly. 7. The board assembly 7 can carry the tray.

[0020] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com