Healthy and environment-friendly trace cutting fluid and preparation method thereof

A cutting fluid and micro-quantity technology, applied in the direction of additives, lubricating compositions, petroleum industry, etc., can solve problems such as large amount of lubricant used, pollution, lubrication and cooling problems can not be solved well

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Add 1000g of dried Sapindus pericarp crushed to 100 mesh, add 4000g of n-propanol solution (concentration: 50%), 125g of paraformaldehyde, use ultrasonic wave to leaching for 24 hours, and filter to remove impurities, which is the pre-micro cutting fluid. body.

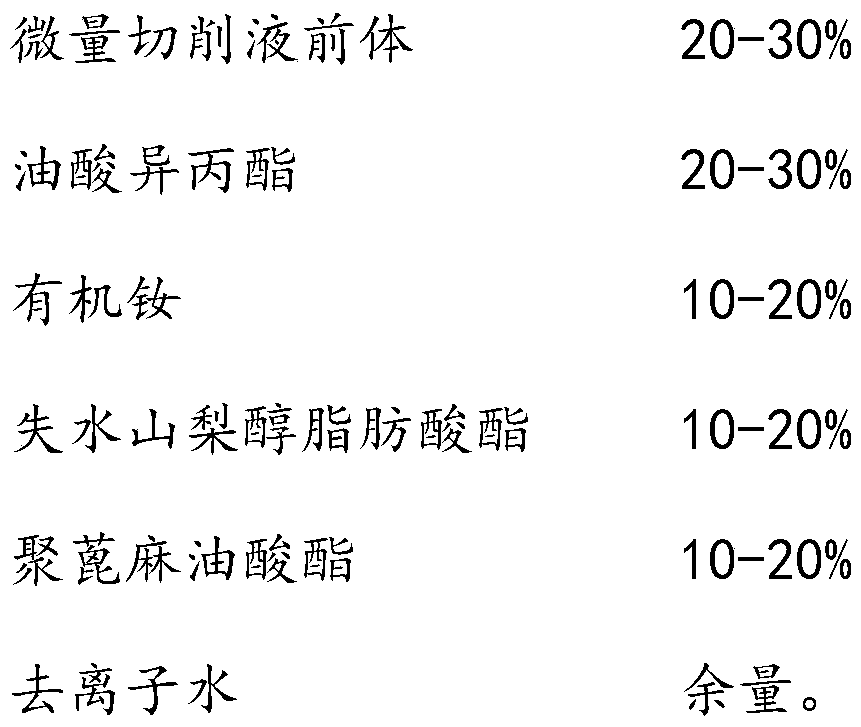

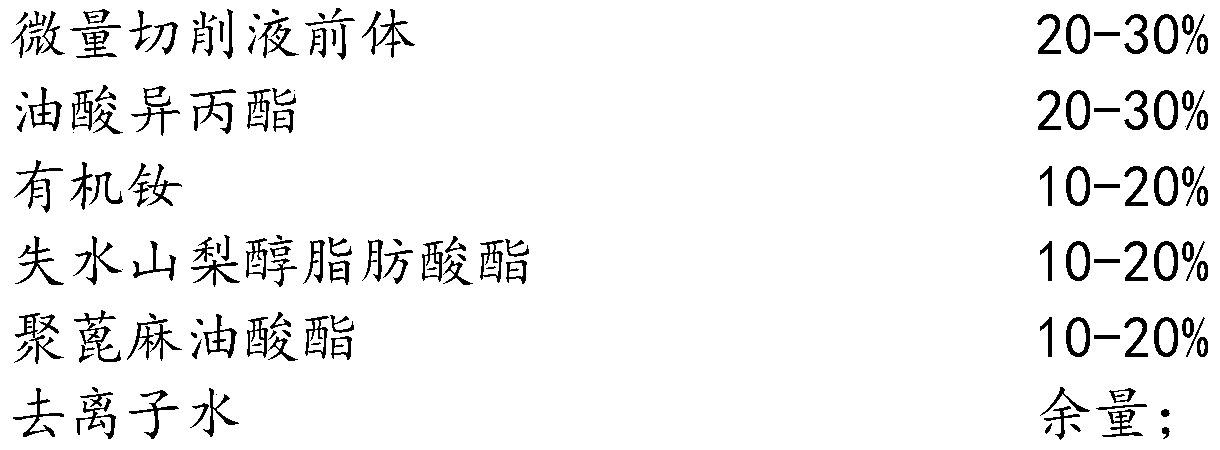

[0031] Weigh 300g of the above trace cutting fluid precursor, 250g of isopropyl oleate, 150g of organic neodymium, 150g of sorbitan fatty acid ester (SP-80), 100g of polyricinoleic acid ester (L4), 50g of deionized water, When it is mixed and stirred at a temperature of 50°C until it becomes transparent, it becomes a healthy and environmentally friendly micro-cutting fluid.

[0032] The preparation method of the organic neodymium is as follows: put 900g of oleic acid and 100g of neodymium oxide into a stirrer, stir and react at a temperature of 100° C. for 3.5 hours, and the organic neodymium is obtained.

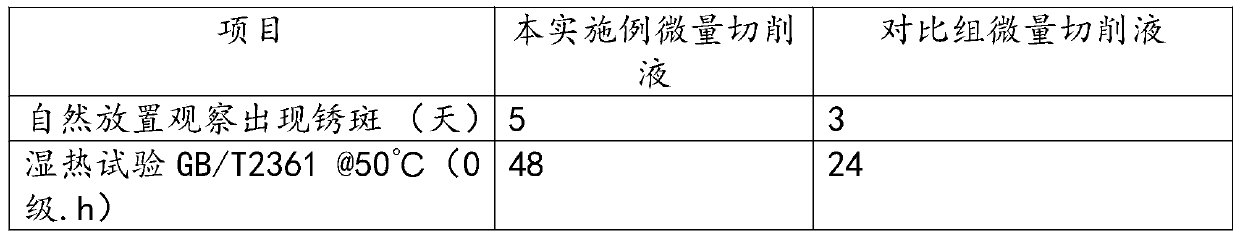

[0033] The above-mentioned micro-cutting fluid and the comparison group micro-cutting fluid (model KS-CU...

Embodiment 2

[0035] Add 1000g of dried Sapindus pericarp crushed to 50 meshes, add 3000g of diethylene glycol solution (concentration 60%), 115g of paraformaldehyde, and use ultrasonic waves to extract for 24 hours, then filter to remove impurities, which is a trace cutting fluid precursor.

[0036] Weigh 200g of the above trace cutting fluid precursor, 300g of isopropyl oleate, 200g of organic neodymium, 100g of sorbitan fatty acid ester (SP-20), 100g of polyricinoleic acid ester (L4), 100g of deionized water, When it is mixed and stirred at a temperature of 40°C until it becomes transparent, it becomes a healthy and environmentally friendly micro-cutting fluid.

[0037] The preparation method of the organic neodymium is as follows: put 850g of oleic acid and 150g of neodymium oxide into a stirrer, stir and react at a temperature of 110° C. for 3 hours to obtain the organic neodymium.

[0038] The above micro-cutting fluid and the comparison group micro-cutting fluid (model KS-CUT320, pr...

Embodiment 3

[0041] Add 5000 g of isopropanol solution (concentration: 55%) to 1000 g of dried Sapindus pericarp crushed to 30 meshes, use ultrasonic waves to extract for 24 hours, and filter to remove impurities, which is the trace cutting fluid precursor.

[0042] Take by weighing 250g of the above-mentioned trace cutting fluid precursor, 200g of isopropyl oleate, 200g of organic neodymium, 120g of sorbitan fatty acid ester (SP-40), 120g of trimerized ricinoleic acid ester, and 110g of deionized water. When it is mixed and stirred at a temperature of ℃ until it is transparent, it is a healthy and environmentally friendly micro-cutting fluid.

[0043] The preparation method of the organic neodymium is as follows: put 880g of oleic acid and 120g of neodymium oxide into a stirrer, stir and react at a temperature of 90° C. for 4 hours, and obtain the organic neodymium.

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com