Anti-cavitation installation for tails of flaring gate piers of stepped spillway

A technology of overflow dam and wide tail pier, which is applied in water conservancy engineering, marine engineering, coastline protection and other directions to reduce the possibility of damage, improve energy dissipation rate, and accelerate dissipation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

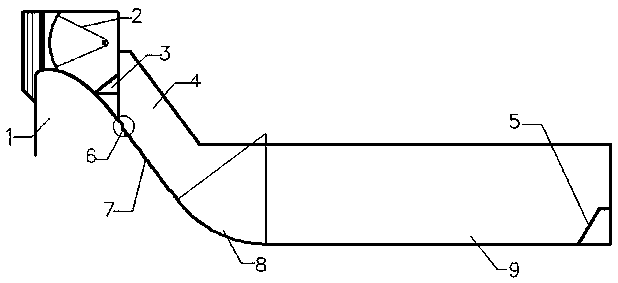

[0026] Embodiment 1: A cavitation facility 6 at the end of the wide tail pier of a stepped overflow dam is applied to a key water conservancy and hydropower project focusing on power generation, taking into account flood control, irrigation and other comprehensive utilization. The maximum working head of the spillway of the power station is 105m, and the design is uniform The slope of the ladder is 53°, and the maximum single-width flow rate is 178m 3 / s.m.

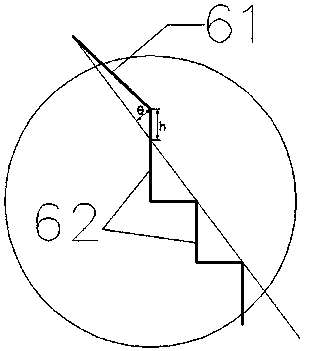

[0027] In this embodiment, the combined energy dissipator of the ridge + new transitional steps is applied to hydraulic flood discharge structures with high water head and large single-width flow, and its structure is as follows Figure 5 , Figure 6 As shown, it includes a riser 61 and a new transition step 62 arranged behind the wide tail pier 3 . The shape of the ridge 61 is "triangular", and its angle θ is 9°≤θ≤11.3°. In this embodiment, three specific angles are selected, which are 9°, 10°, and 11.3° respectively, ...

Embodiment 2

[0030] Embodiment 2: An anti-cavitation facility 6 at the end of the wide pier of a stepped overflow dam is used for steps with an average step gradient of 53°, and is used in flood discharge structures with high water head and large single-width flow.

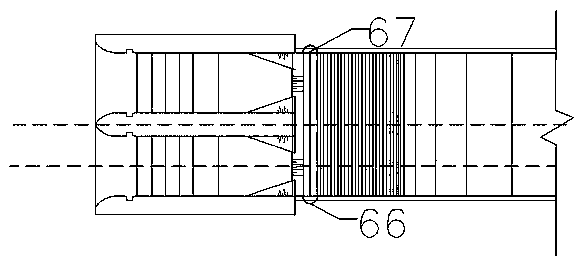

[0031] The air defense facility at the end of the wide tail pier of a stepped overflow dam in this embodiment has a structure such as Figure 7 , 8 As shown, it includes a riser 61 and a new transition step 62 arranged behind the wide tail pier 3 . The shape of the ridge 61 is "triangular", and its angle θ is 9°≤θ≤11.3°. In this embodiment, three specific angles are selected, which are 9°, 10°, and 11.3° respectively, and its height h=1m. Followed by a corbel-shaped aeration tank 65 transition ladder 62, the transition ladder is made up of 2 steps with a height of 2m and a width of 1.5m, and a corbel-shaped aeration tank 65, such as Figure 7 , 8 , the corbel-shaped aeration groove 65 refers to the backward extension distan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com