A ground connection component

A technology for connecting components and components, which is applied in the direction of connecting components, connections, thin plate connections, etc., can solve the problems of poor connection performance, poor conductivity, poor conductivity, etc., and achieve high connection reliability, prevent reverse loosening, Effect of improving electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

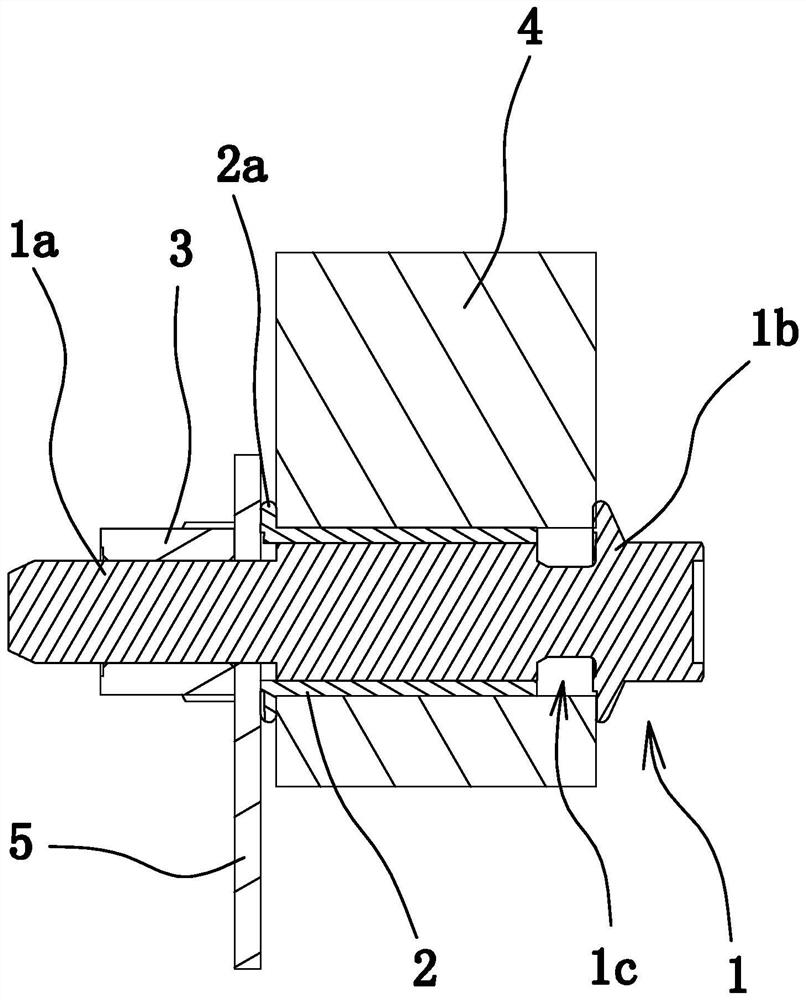

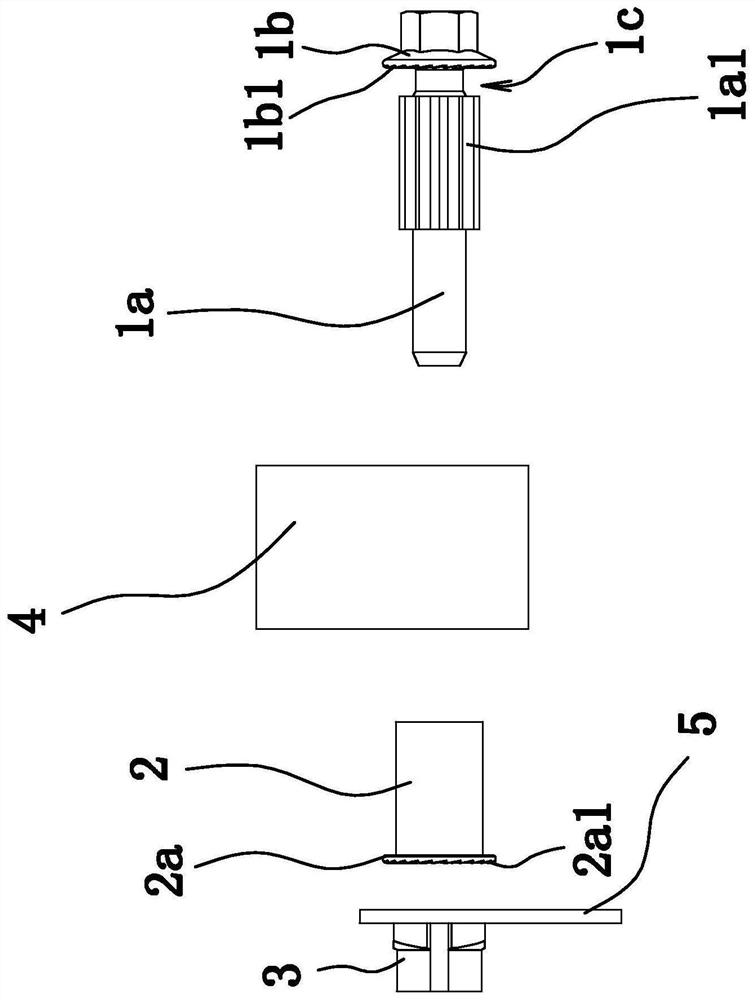

[0030] Such as Figure 1-4 As shown, the first part 4 and the second part 5 of the ground connection assembly are used for overlapping, the first part 4 and the second part 5 are coated with a coating, and the second part 5 is fixed with a lock nut 3 by welding. The ground connection assembly includes a bolt 1 and a conductive intermediate capable of conducting electricity. In this embodiment, the conductive intermediate is a conductive sleeve 2, and both the bolt 1 and the conductive sleeve 2 are made of conductive metal materials.

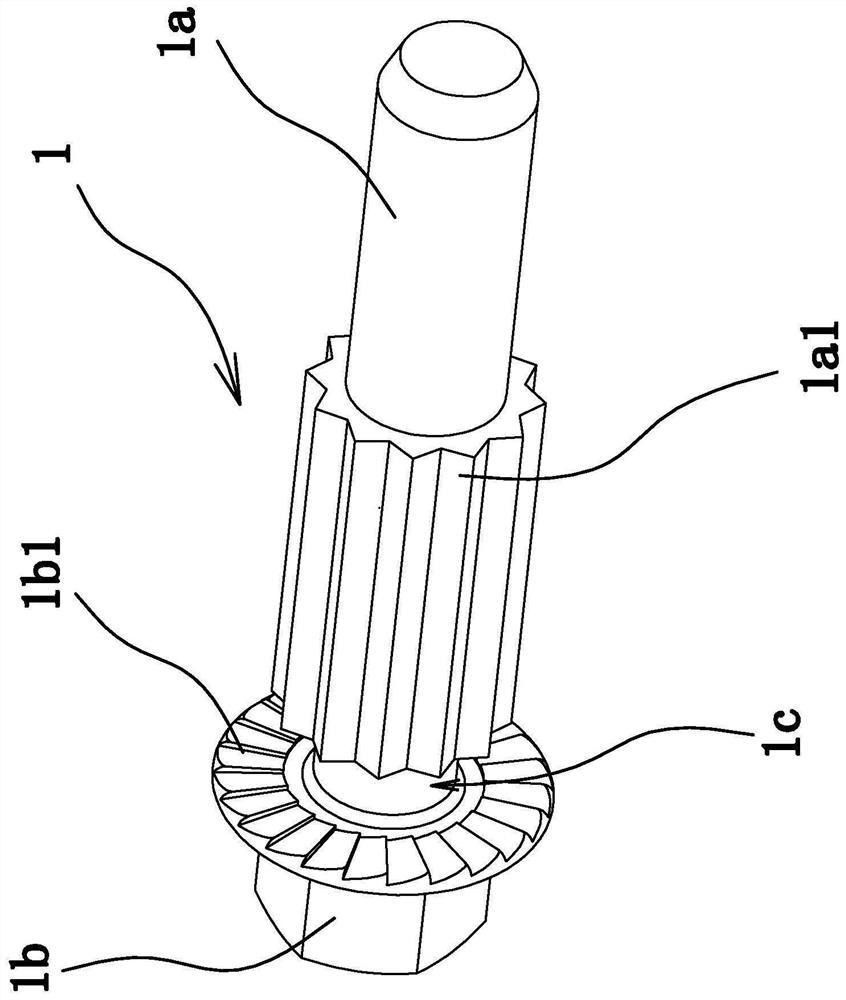

[0031] Such as image 3 As shown, specifically, the bolt 1 includes a screw part 1a and a head 1b, the head 1b is arranged on the end face of one end of the screw part 1a, and the end face of the head 1b close to the screw part 1a has a scraping part-1b1 . The screw part 1a has a gear part 1a1, and the inner wall of the conductive sleeve 2 is correspondingly provided with tooth grooves 2b. The conductive sleeve 2 is sleeved on the screw part 1a...

Embodiment 2

[0036] The structural features of this embodiment are basically the same as those of Embodiment 1, the difference is that the inner hole of the conductive sleeve 2 is polygonal, and the screw part 1a has a protruding and polygonal plug-in part correspondingly, and the plug-in part can be It is plugged into the inner hole of the conductive sleeve 2 and leans against the hole wall of the inner hole. Through the cooperation of the polygonal inner hole and the corresponding polygonal plug-in part, the circumference between the conductive sleeve 2 and the bolt 1 can be realized. direction, so as to realize the synchronous rotation of the bolt 1 and the conductive sleeve 2.

[0037] The socket part protrudes radially from the surface of the screw part 1a, and an annular concave shoulder 1c is formed between the socket part and the head 1b of the bolt 1, so that there is a certain accommodation space between the socket part and the head 1b of the bolt 1, Scraping part-1b 1 In the pro...

Embodiment 3

[0039] The structural features of this embodiment are basically the same as those of Embodiment 1, the difference is that: there are several protruding connecting protrusions on the screw part 1a, and several slots are correspondingly opened on the inner wall of the conductive sleeve 2, and the conductive sleeve 2 Sleeved on the screw part 1a and the connecting protrusion can be embedded in the corresponding slot, so as to realize the circumferential fixation between the conductive sleeve 2 and the bolt 1, so that the bolt 1 and the conductive sleeve 2 can rotate synchronously. The screw part 1a is in close contact with the inner wall of the conductive sleeve 2 and the connecting protrusion and the inner wall of the slot, which can ensure a larger contact area between the conductive sleeve 2 and the bolt 1 and ensure better electrical conductivity.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com