Control method and control device of deep peak shaving boiler and thermal power generation system

A boiler control and peak shaving technology, applied in the control system, combustion method, controlled combustion and other directions, can solve problems such as fire extinguishing and loss of stability of combustion in the furnace, reduce heat loss, meet the needs of remote control, and avoid instability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

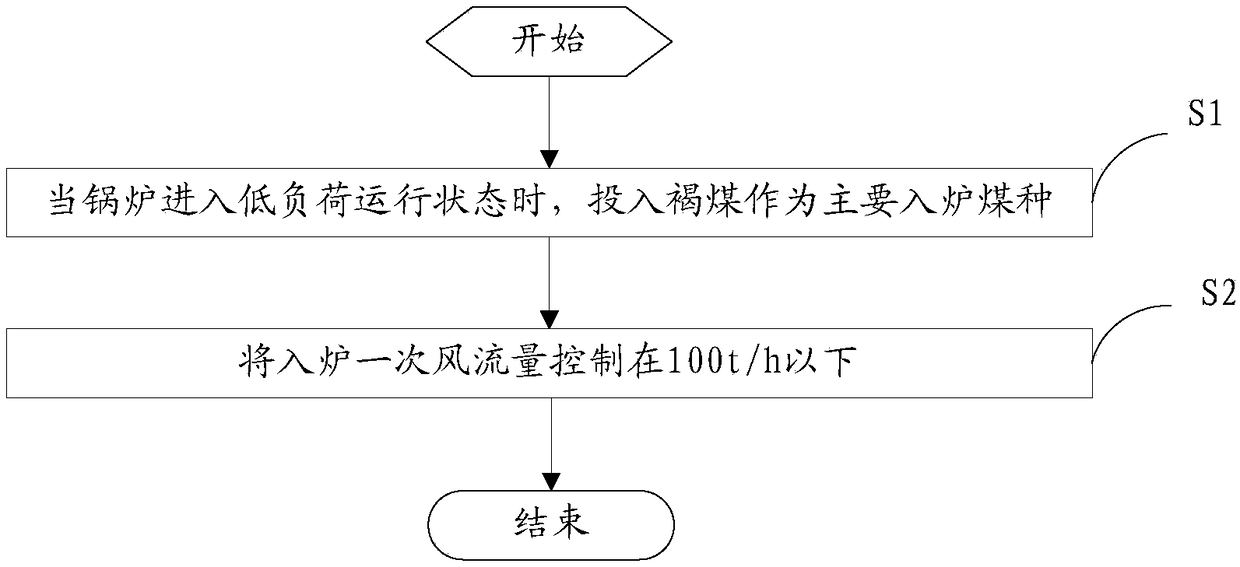

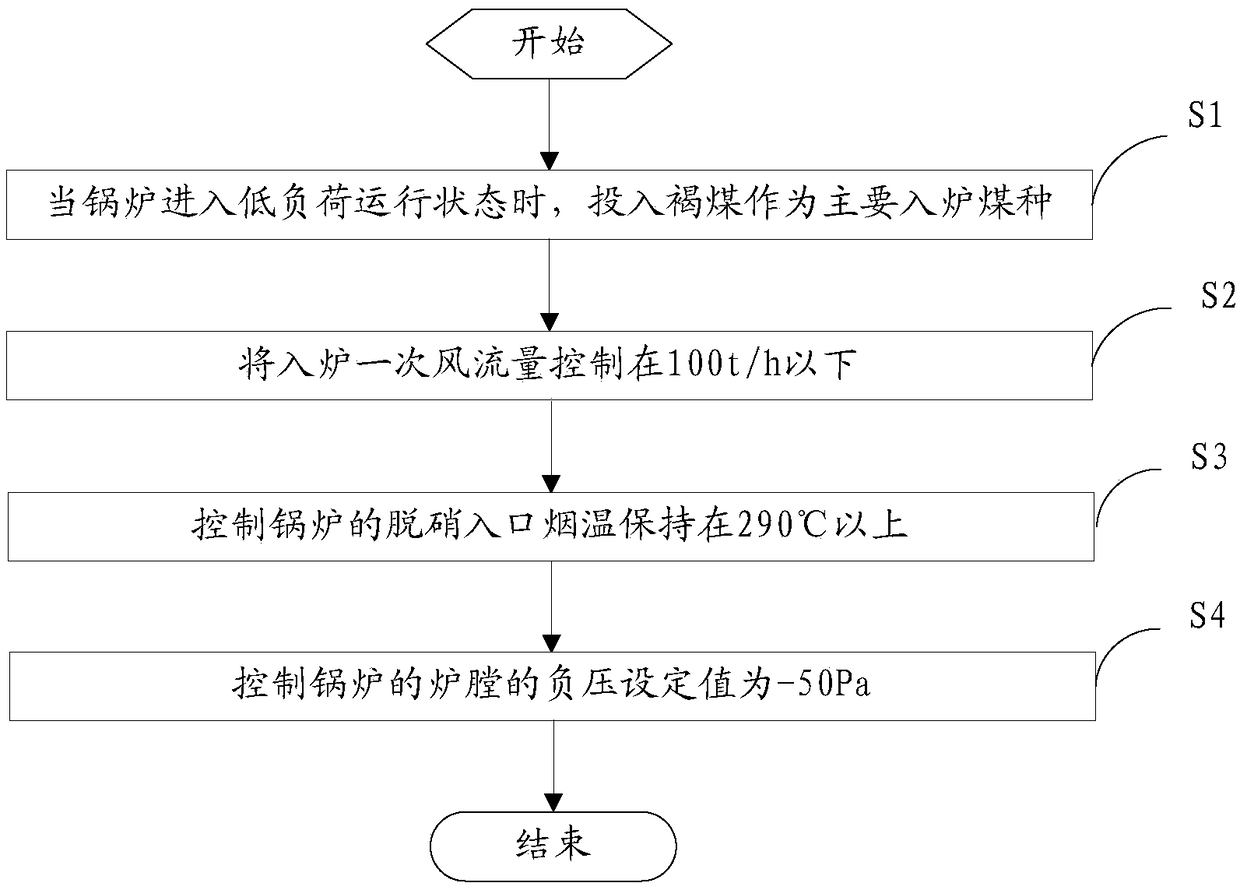

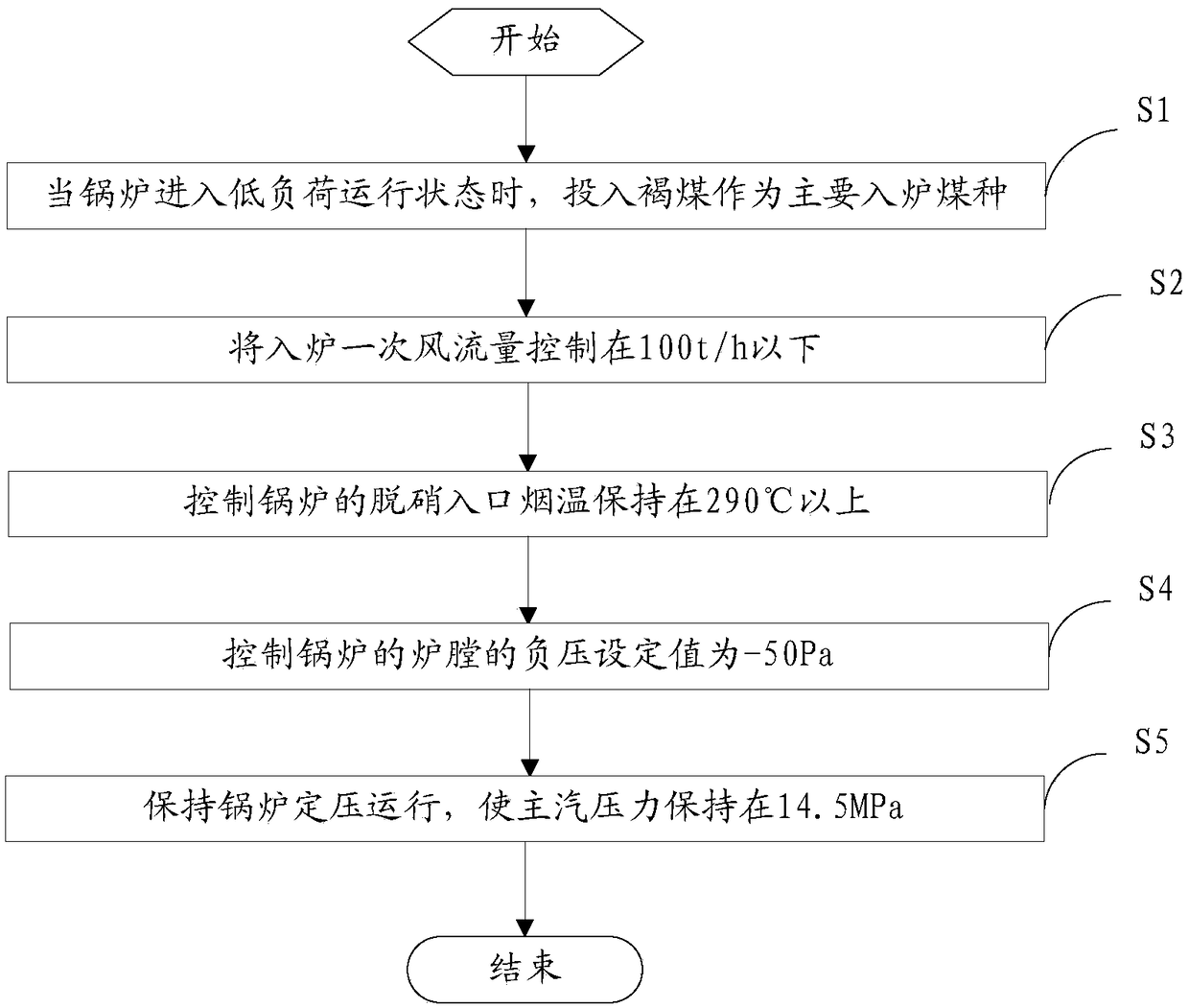

[0045] figure 1 It is a flow chart of the steps of a control method for a deep peak-shaving boiler provided in the embodiment of the present application.

[0046] Such as figure 1 As shown, the deep peak-shaving boiler control method provided in this embodiment is applied to a boiler of a 600MW thermal power generation system. In order to achieve stable combustion of the boiler during low-load operation, it is necessary to ensure that the temperature in the furnace does not drop, so that the fuel after entering the furnace can be continuously burned to maintain normal operation. Therefore, the deep peak regulation control method of the present application specifically includes the following steps:

[0047] S1. When the boiler enters the low-load operation state, input lignite as the main type of coal into the furnace.

[0048] When the unit is running at low load, lignite is used as the main furnace coal. Since lignite has a lower calorific value than bituminous coal, it ca...

Embodiment 2

[0069] Figure 4 A structural block diagram of a control device for a deep peak-shaving boiler provided in an embodiment of the present application.

[0070] Such as Figure 4 As shown, the deep peak-shaving boiler control device provided in this embodiment is applied to a boiler of a 600MW thermal power generation system. In order to achieve stable combustion of the boiler during low-load operation, it is necessary to ensure that the temperature in the furnace does not drop, so that the fuel after entering the furnace can be continuously burned to maintain normal operation. Therefore, the deep peak shaving control device of the present application specifically includes a coal feeding control module 10 and an air volume control module 20

[0071] The coal input control module is used to control the coal input equipment to input lignite as the main coal type when the boiler enters the low-load operation state.

[0072] When the unit is running at low load, lignite is used as...

Embodiment 3

[0101] This embodiment provides a thermal power generation system, the thermal power generation system at least includes a boiler, and the boiler is provided with the deep peak-shaving boiler control device provided in the previous embodiment. The control device is used to put lignite into the furnace as the main coal type when the boiler enters the low-load operation state; strictly control the primary air flow into the furnace, and control the primary air flow below 100t / h. Through the above measures, the fuel supply into the furnace can be stabilized, continuous combustion can be ensured and sufficient heat can be continuously released to maintain the temperature in the furnace, unnecessary heat loss can also be reduced, and the temperature in the furnace will not drop, so that the boiler can operate at low load. During the operation, the combustion can be stable, so as to avoid the combustion in the furnace from being extinguished due to instability.

[0102] In this appli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com