Test method for detecting graphitization temperature

A technology of graphitization temperature and test method, which is applied in the application of thermometers, chemical instruments and methods, thermometers, etc., can solve the problem that the final temperature of graphitization treatment cannot be measured, and achieves the effect of clear thinking, cost reduction and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

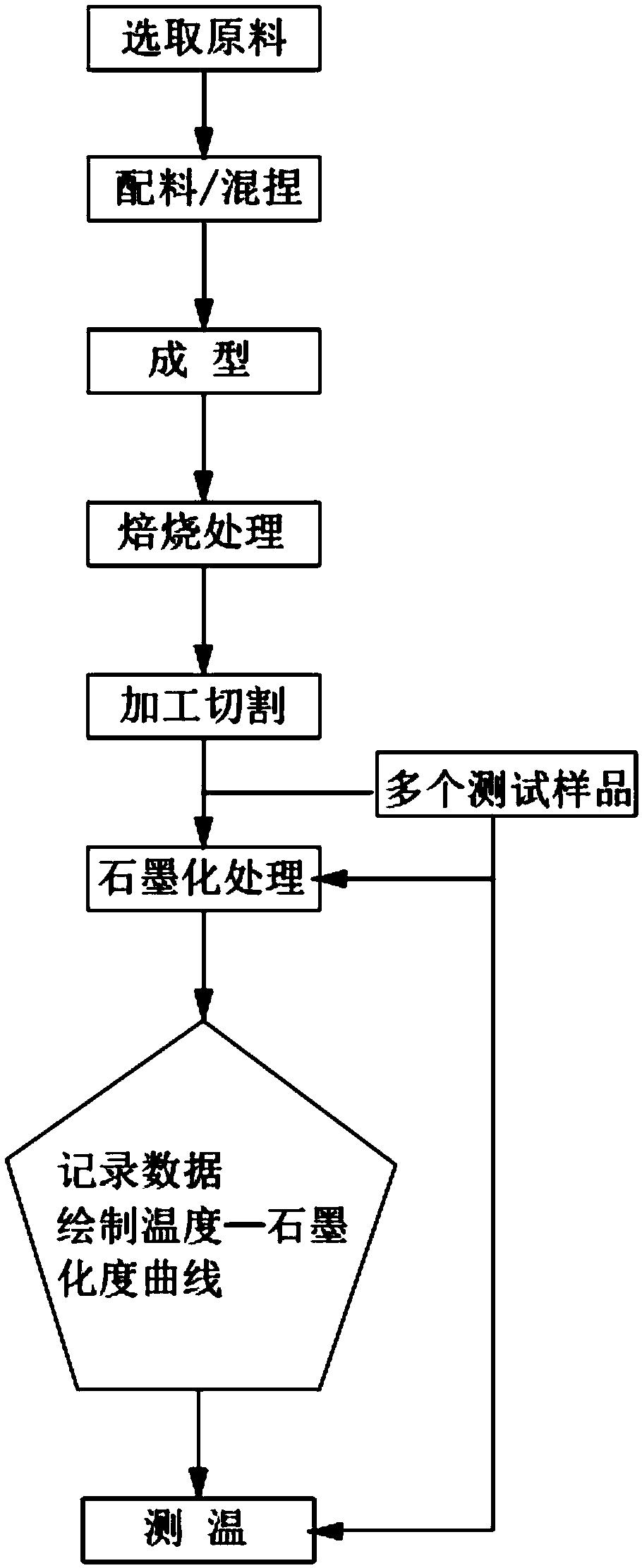

[0040] Such as figure 1 Shown, a kind of test method for detecting graphitization temperature, comprises the following steps:

[0041] Step 1, selecting raw materials, mixing coke aggregate and binder according to the ratio;

[0042] Step 2, kneading, kneading the mixed coke aggregate and binder to form a paste. The kneading temperature is 150-200° C., and the kneading time is 10-30 minutes;

[0043] Step 3, molding, molding the kneaded paste under a pressure of 100-200MPa, and keeping the pressure for 10-40min to form a green body;

[0044] Step 4, roasting, roasting the green body at 400-700°C for 1-3 hours to form a roasted product;

[0045] Step 5, reprocessing, processing the roasted product into a disc sample with a diameter of 20-30 mm and a thickness of 1-3 mm, and the diameter and thickness of the disc sample are consistent;

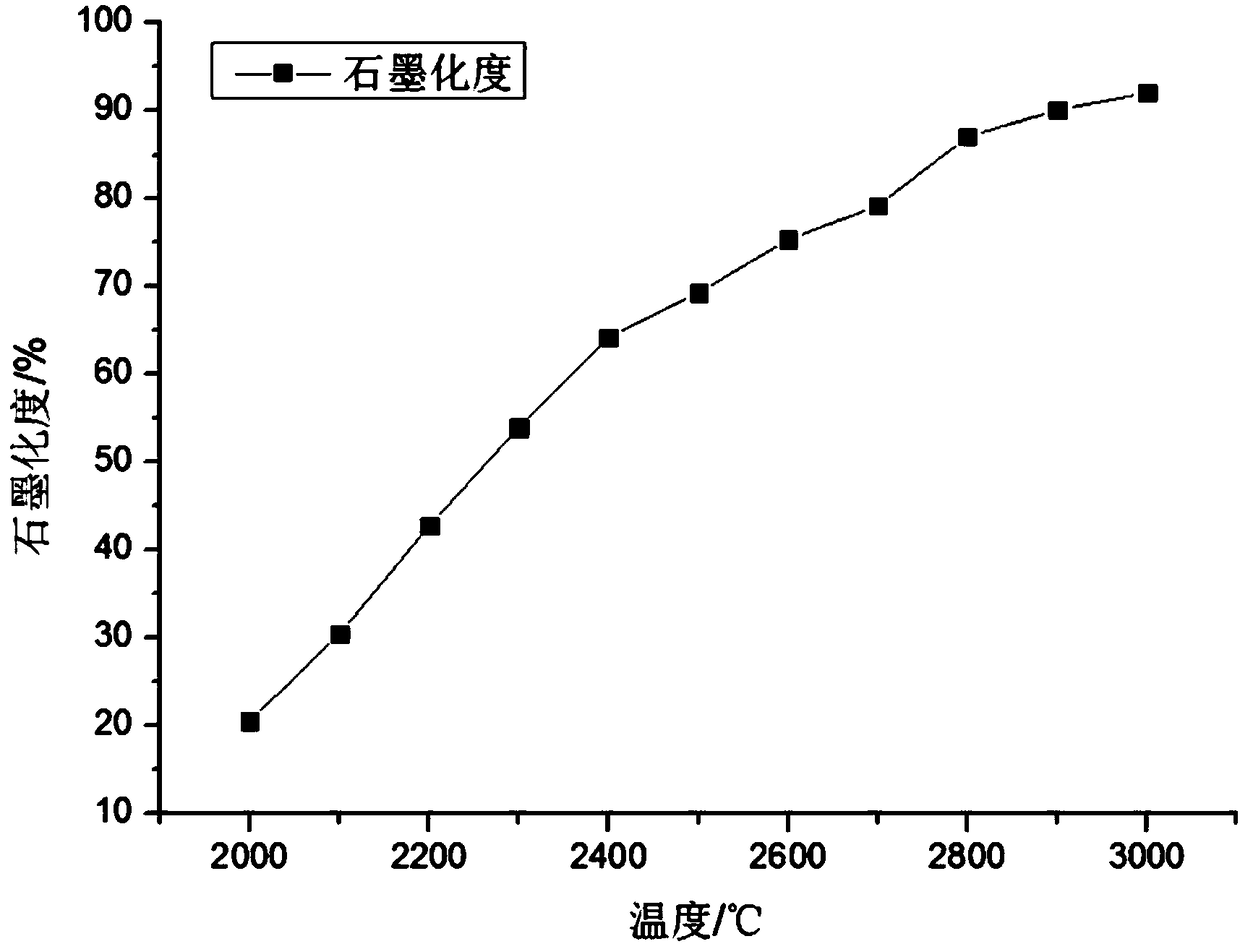

[0046] Step 6, draw the temperature-graphitization degree curve, select multiple temperature points as the graphitization temperature, respe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com