A color matching instrument of optimized color difference resolution and testing method

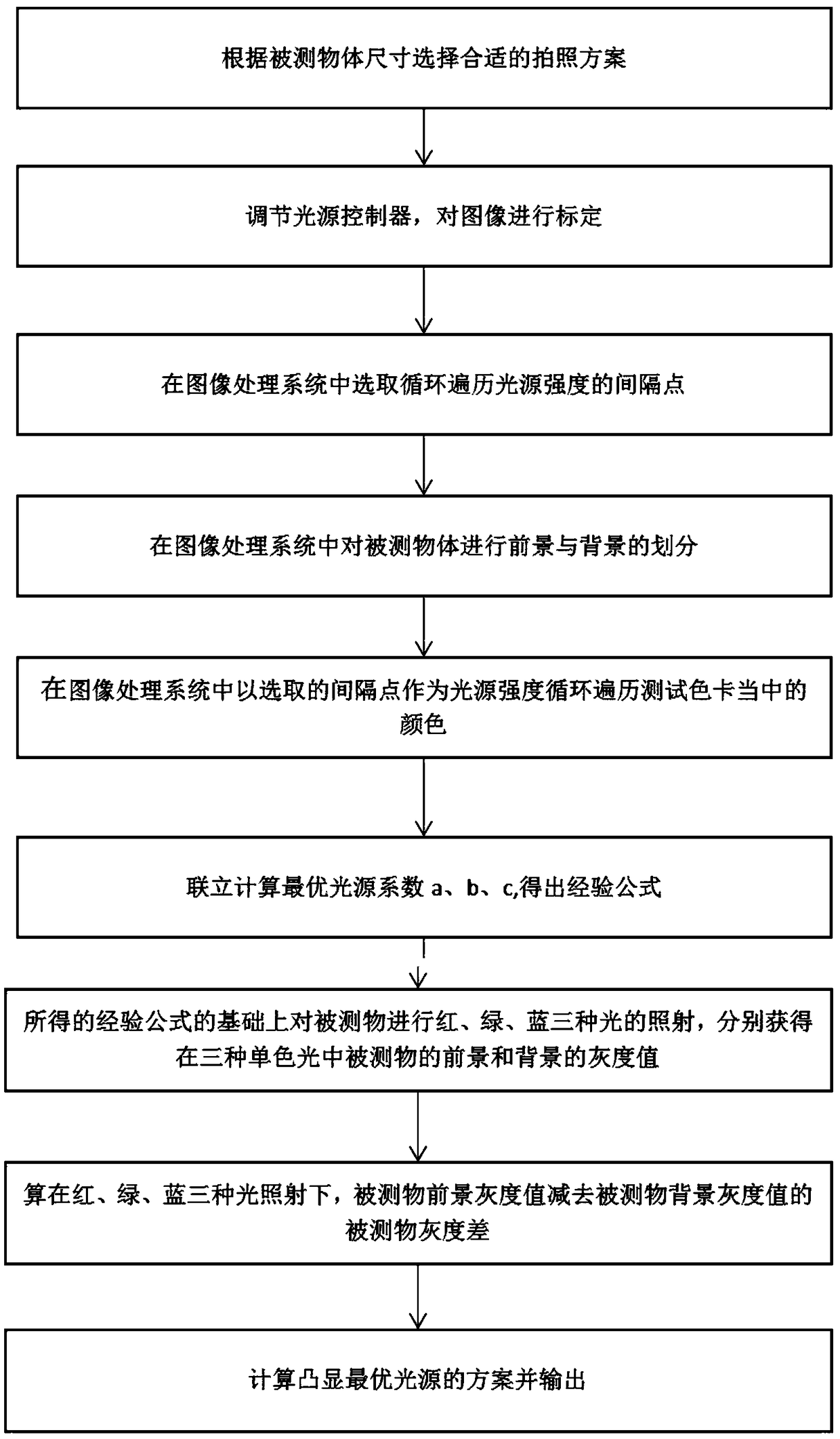

A testing method and optimal technology, applied in optical instrument testing, testing optical performance, testing of machine/structural components, etc., can solve the problem of poor ability to distinguish chromatic aberration, increase the difficulty of segmentation and identification of image processing algorithms, and cannot improve system positioning. and measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] The content of the present invention will be further described below in conjunction with specific examples, but it should not be construed as a limitation of the present invention.

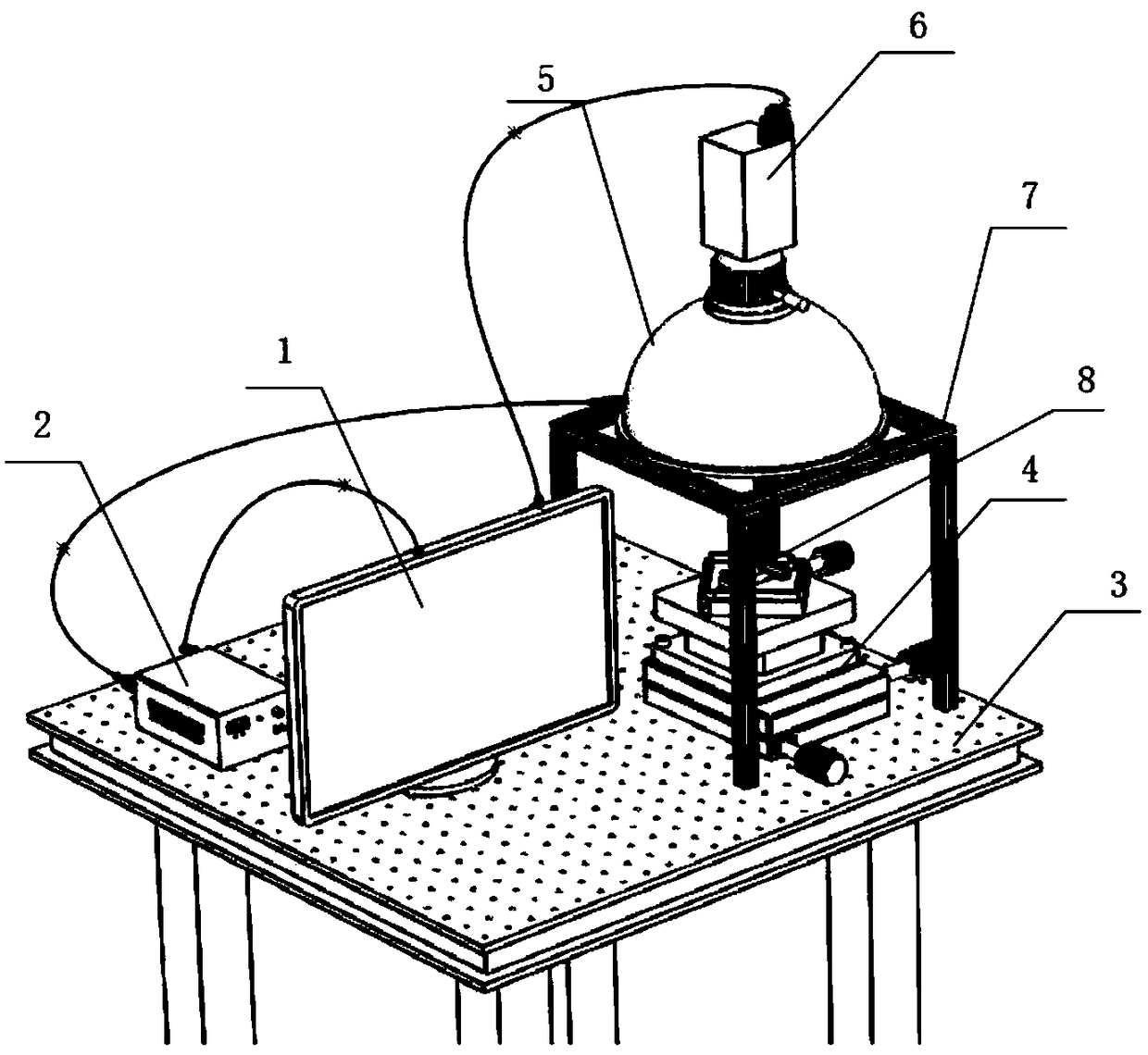

[0059] Such as figure 1 As shown, a color difference optimal resolution color matching instrument includes an image processing system 1, a light source controller 2, a black and white industrial camera 6, a dome light source 5 and a platform, and the dome light source 5 includes a red light source, a green light source and A blue light source, the platform includes a base platform 3 and a mobile platform 4, the image processing system 1 and the mobile platform 4 are fixed on the base platform 3, and an aluminum profile is placed above the mobile platform 4 Support 7, the support 7 fixes the dome light source 5, the lens of the black-and-white industrial camera 6 is coaxially installed on the top of the dome light source 5, and the dome light source 5 forms reflected light through the dome, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com