Cable reciprocating twisting test device

A torsion test and cable technology, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve problems such as failure to implement, and achieve the effects of convenient maintenance and replacement, prevention of deflection, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

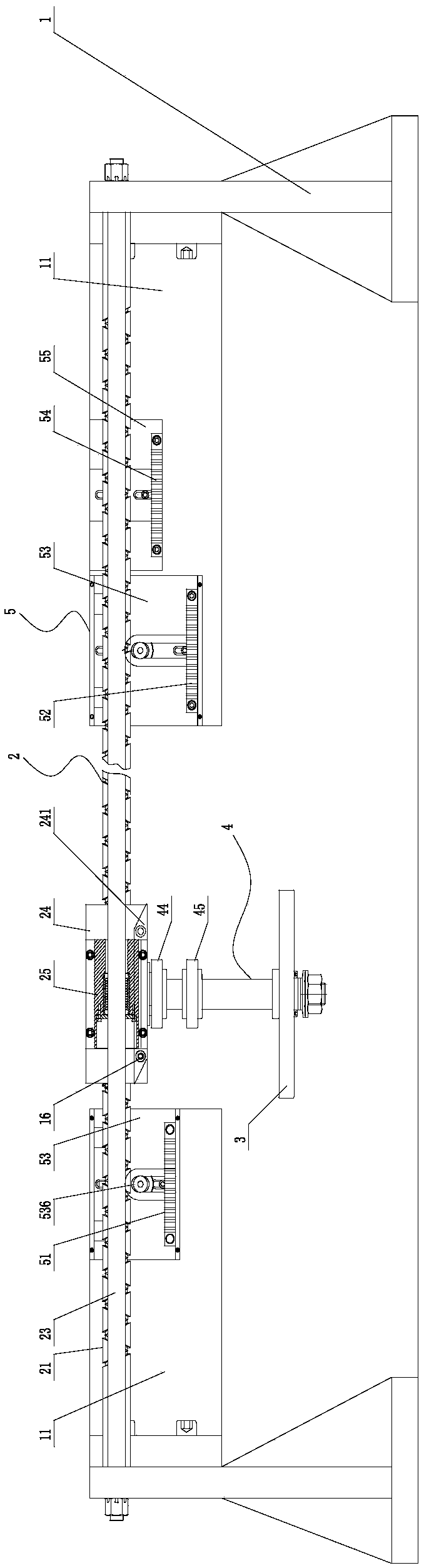

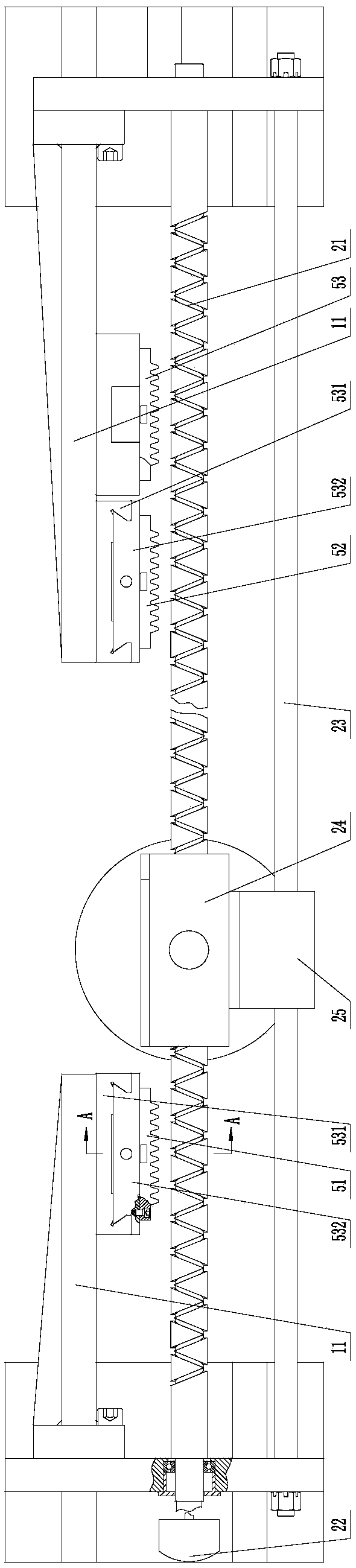

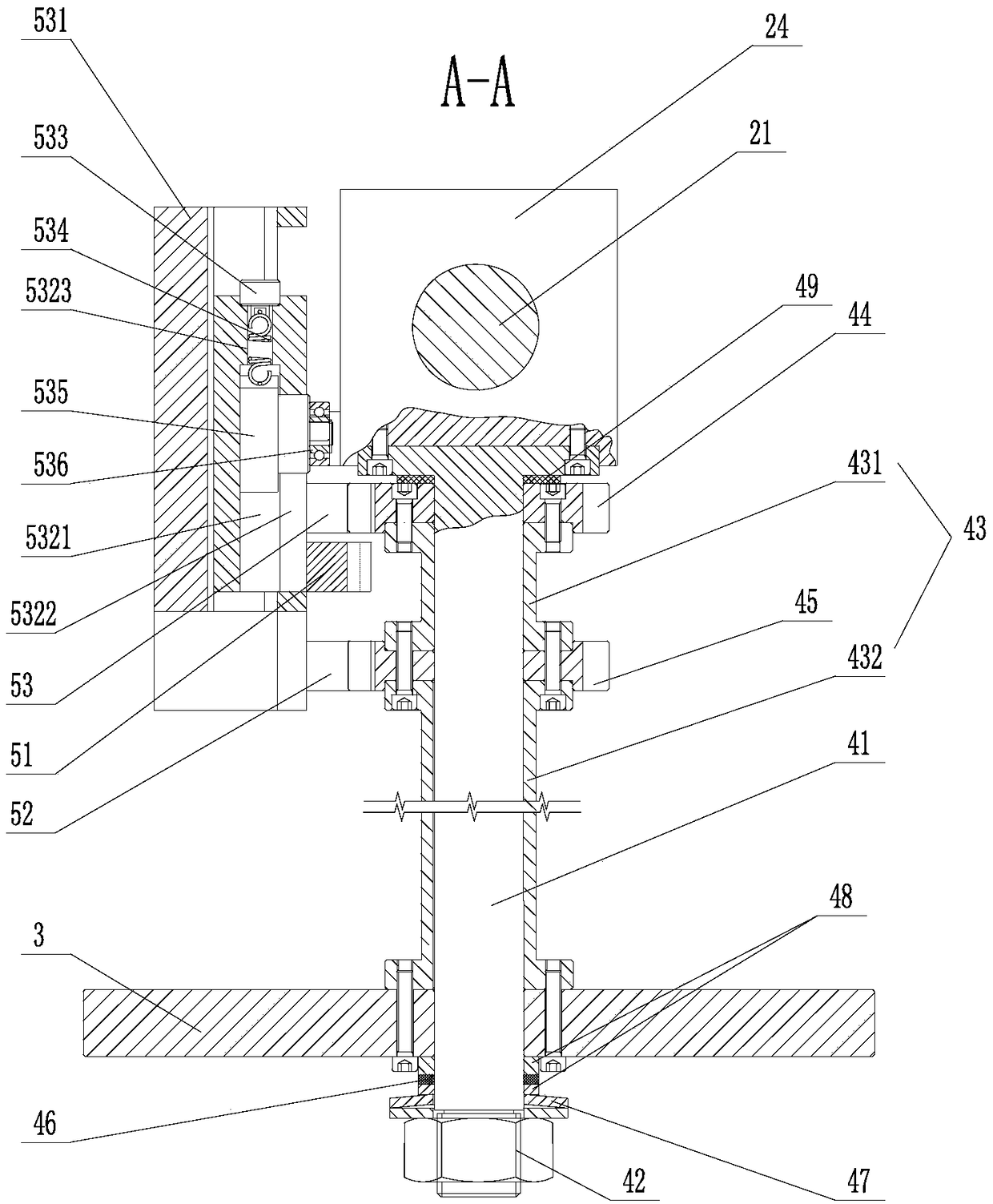

[0030] See Figure 1 to Figure 3 , The cable reciprocating torsion test device of this embodiment includes a frame 1, a transmission mechanism 2, a cable torsion plate 3, a rotating mechanism 4 and a sliding mechanism 5.

[0031] The transmission mechanism 2 is arranged on the frame 1 . Specifically, the transmission mechanism 2 includes a lead screw 21, a reduction motor 22, a polished rod 23, a reciprocating nut 24 and a bearing seat 25. The lead screw 21, the reduction motor 22 and the polished rod 23 are all arranged on the frame 1. 21 connected, used to drive the screw 21 to rotate forward and backward, the polished rod 23 is set on one side of the screw 21 and is parallel to the screw 21, the reciprocating nut 24 is set on the screw 21, and the bearing seat 25 is set on the polished rod 23 In this way, the bearing seat 25 can slide back and forth on the polished rod 23, and the reciprocating nut 24 is fixedly connected with the bearing seat 25. When the screw 21 rotates...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com