Coring device for roadbed soil and method for installing moisture sensor by using coring device

A technology for coring device and roadbed soil, which is applied to measuring devices, instruments, scientific instruments, etc., can solve the problems of easy loosening of soil core samples, easy damage to moisture sensors of backfill, and easy water ingress of moisture sensors, so as to prevent loose soil samples. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

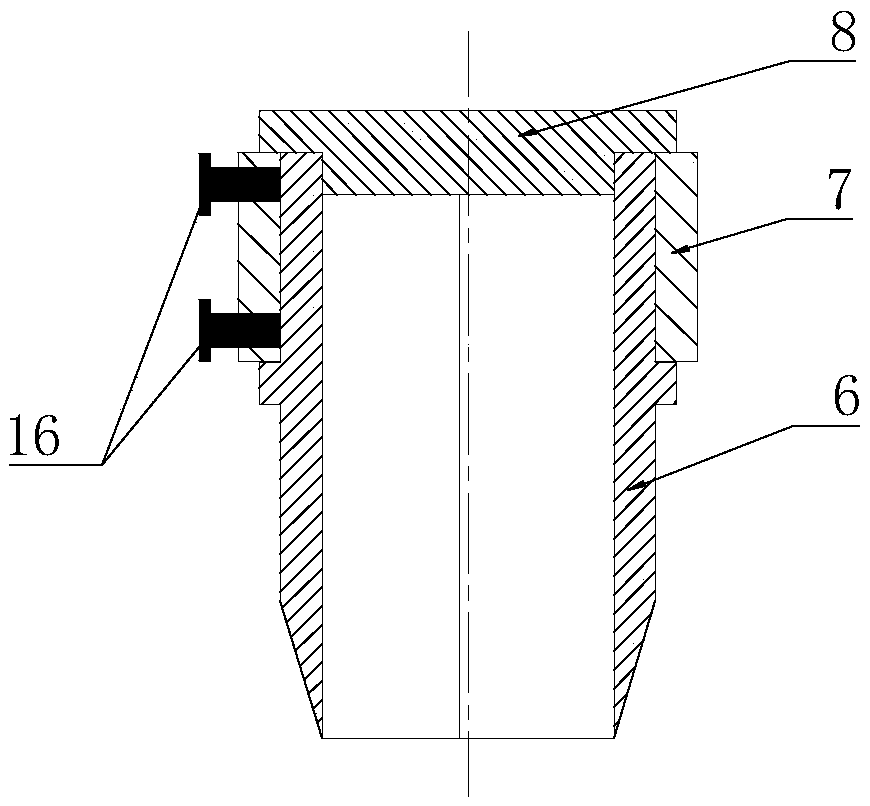

[0030] Specific implementation mode one: combine Figure 1-Figure 4 Illustrate this embodiment, the coring device for subgrade soil described in this embodiment, it includes blade 6, restraining ring 7, spacer 8 and a plurality of top wires 16; Process the limit protrusion of the restraint ring, the restraint ring 7 is an annular sleeve body, the side wall of the annular sleeve body is provided with a plurality of jacking wires 16, the restraining ring 7 is sleeved on the top of the knife body 6, each jacking wire 16 The top is supported on the outer wall of the knife body 6, and the cushion block 8 covers are contained on the knife body 6 and the restraining ring 7.

[0031] In this embodiment, the inner diameter of the blade body 6 is 70mm, and the blade angle of the blade body 8 is 17°.

specific Embodiment approach 2

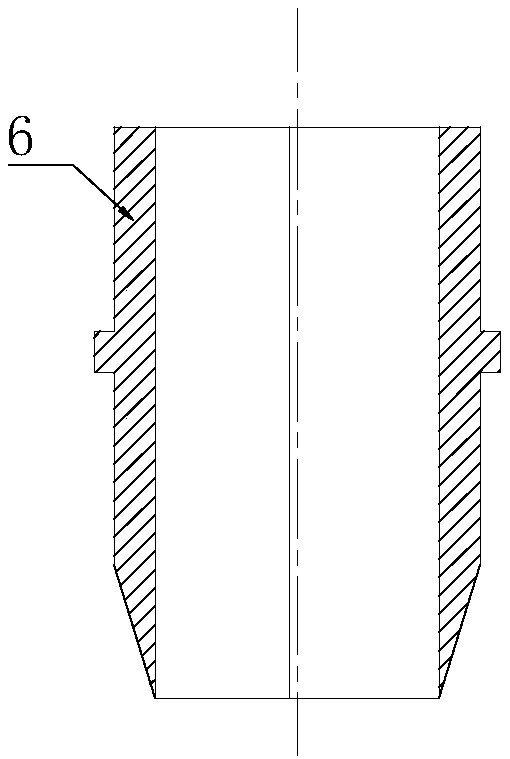

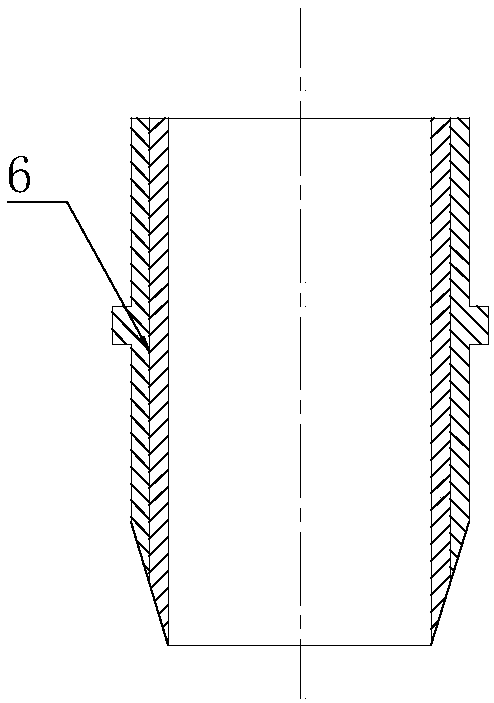

[0032] Specific implementation mode two: combination Figure 1-Figure 4 Describe this embodiment, the coring device for subgrade soil described in this embodiment, the knife body 6 is formed by two semi-annular cylinders fastened together to form an annular cylinder, and the inner walls of the two sides of one semi-annular cylinder are respectively processed with One vertical protrusion, the inner wall of the two sides of the other semi-annular cylinder is respectively processed with a vertical groove corresponding to the vertical protrusion, and each vertical protrusion on the two sides of the semi-annular cylinder corresponds to It is arranged in a vertical groove on both sides of the other semi-annular cylinder, and the vertical protrusions and vertical grooves are arranged correspondingly to increase the matching performance of the two semi-annular cylinders and prevent the two semi-annular cylinders from Relative sliding occurs, and other components and connections are th...

specific Embodiment approach 3

[0033] Specific implementation mode three: combination Figure 1-Figure 3 Describe this embodiment, the coring device for subgrade soil described in this embodiment, the section of the blade body 6 near the bottom end side wall is a wedge-shaped surface, and the cross-section of the wedge-shaped surface shrinks sequentially from top to bottom, and the bottom end of the blade body 6 is a blade portion , the edge angle of the blade portion is 17°, the effect of this structure is to insert the blade body 6 on the roadbed faster when using the blade body 6 for work, so as to increase work efficiency, and the other composition and connection relationship are the same as the specific embodiment one .

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com