Dummy bar head machining system and machining method

A processing system and processing method technology, applied in general control systems, control/regulation systems, instruments, etc., can solve problems such as low production efficiency, difficult processing of dummy heads, and uneven product quality, so as to save material costs, The effect of reducing operation steps and saving labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

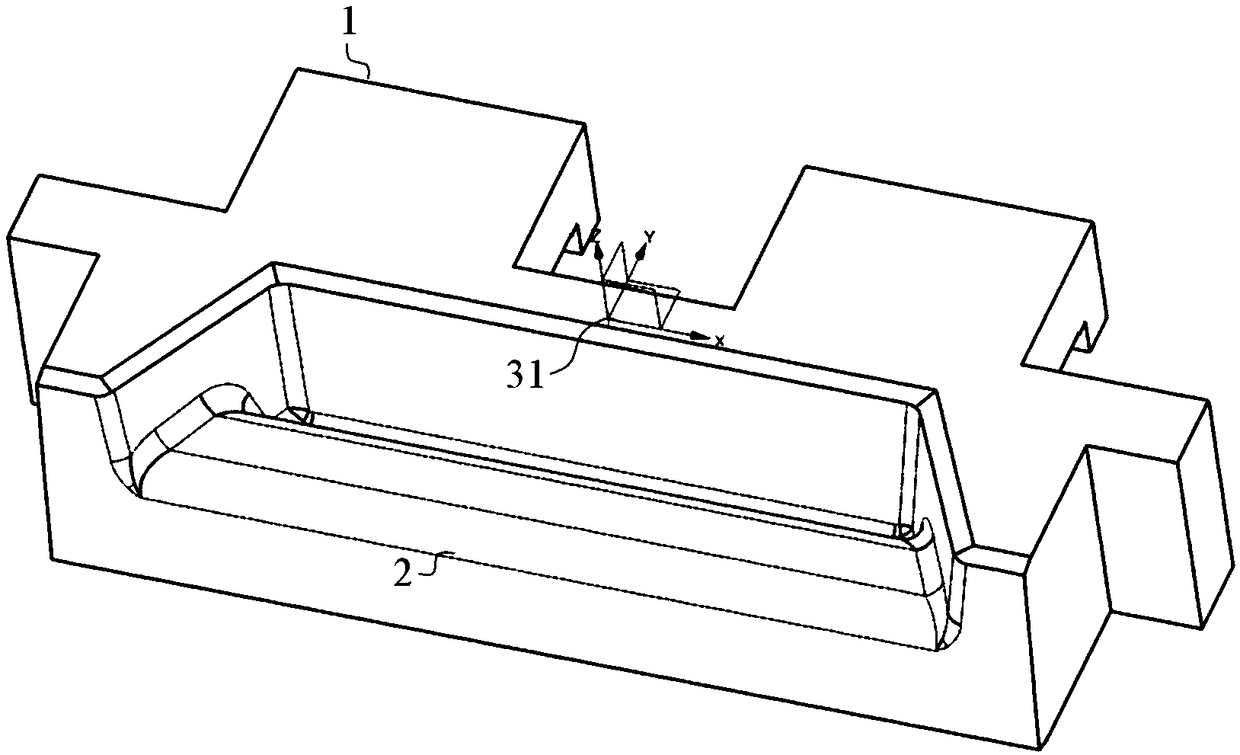

[0040] The dummy head processing system of this embodiment is used for processing the curved surface structure of the dummy head, including:

[0041] The pattern input module can draw or collect the pattern information of the surface structure 2 of the dummy head to be processed, and can convert the pattern information into an initialization pattern exchange specification file for transmission.

[0042] The pattern input module mainly presents a user interface with two functions on the screen of the smart terminal device, one is an interface for importing pattern files drawn in other terminals or programs, and the other is an interface for users to draw patterns; pattern A data transmission sub-module is loaded in the input module, so that the pattern input module has the function of directly reading in the pattern files drawn by other graphic design programs and the function of outputting the format of the initialization graphic exchange specification file format. The pattern ...

Embodiment 2

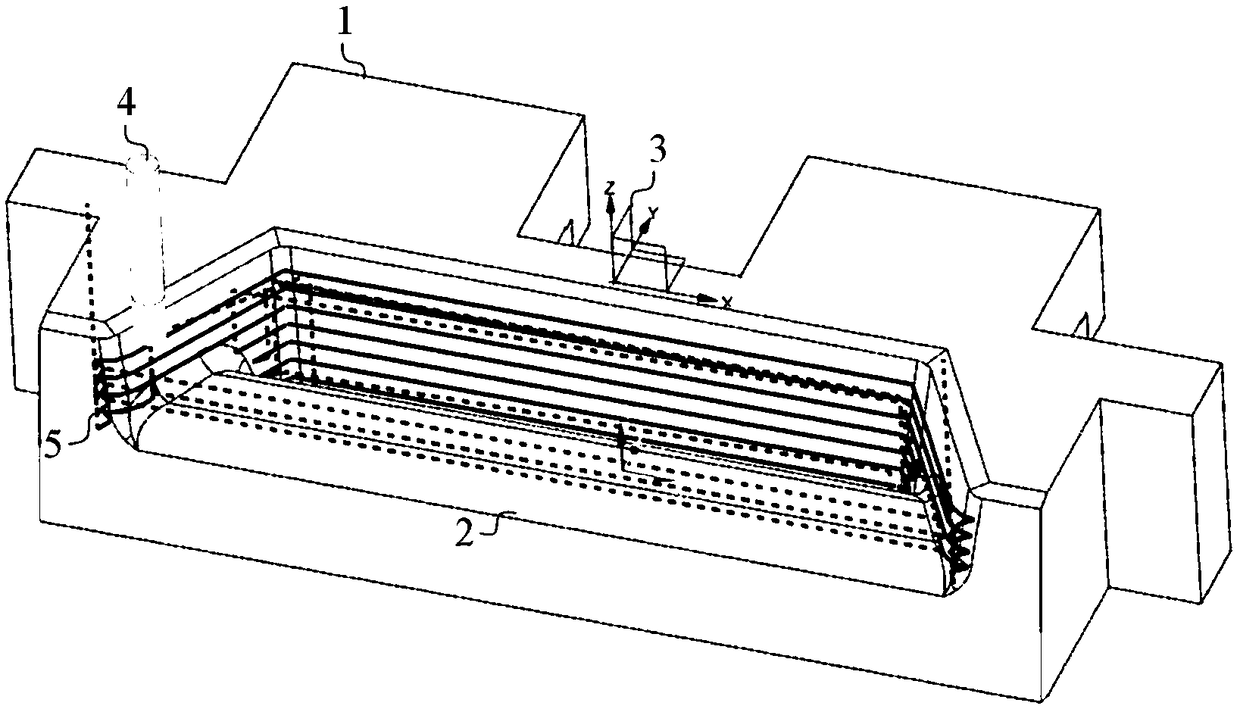

[0053] The dummy head processing system of this embodiment is further improved on the basis of Embodiment 1. The formulation of the processing plan in the NC programming module includes tool selection, processing method selection, processing route selection and cutting parameter calculation. When formulating the processing plan, flat bottom milling cutters and ball end milling cutters 4 with different diameters are selected as the processing tools, and the processing methods of layered contour finishing and multi-tool cleaning of curved surfaces are selected. The user can select a suitable tool on the user interface of the CNC programming module according to the tool conditions in the workshop. For the surface structure of the dummy head to be processed in the present invention, the default tool selection provided by the user interface is flat bottom milling cutter and ball end Milling cutter 4, more specifically ¢80 corn milling cutter, ¢32 corn ball end milling cutter and ¢40...

Embodiment 3

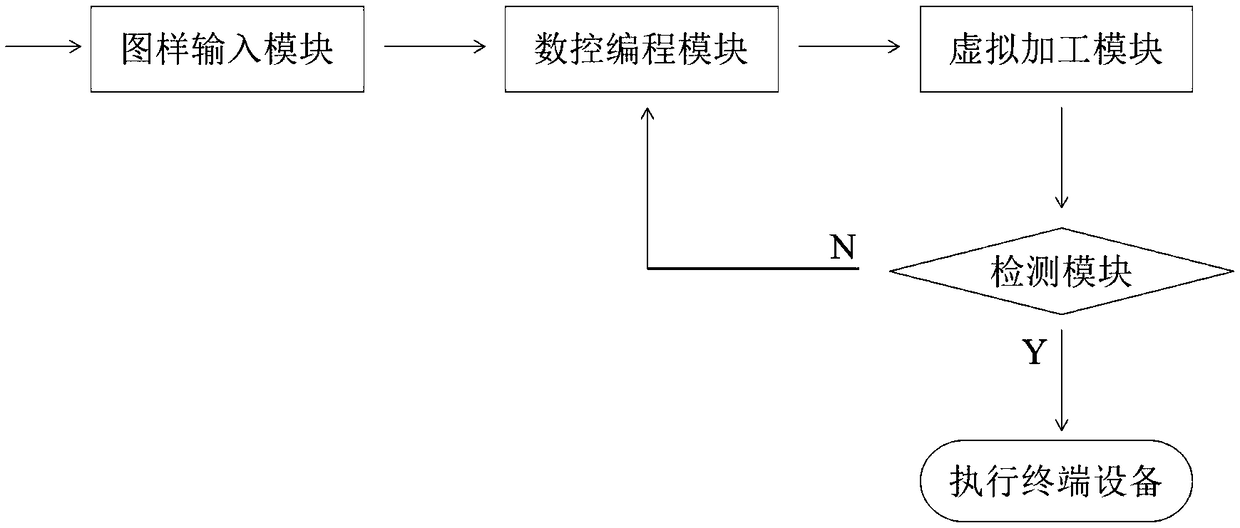

[0055] The dummy head processing system of this embodiment is further improved on the basis of embodiment 2, and also includes a virtual processing module, which can receive the numerical control program transmitted by the numerical control programming module, and perform the surface structure of the dummy head to be processed according to the numerical control program. The virtual machining of the machine transforms the machined model into an initialization graphics exchange specification file. It also includes a detection module, which detects whether the NC program can run completely in the virtual processing module. If not, it sends a signal to the NC programming module, and the NC programming module re-establishes the processing plan; if so, compares the model after virtual processing with the dummy ingot to be processed Whether the pattern information of the head curved surface structure 2 is the same, if so, send a signal to the NC programming module to send the NC progr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com