Integrated PCA-ICA blast furnace process monitoring and fault diagnosis method

A process monitoring and fault diagnosis technology, applied in program control, electrical test/monitoring, test/monitoring control system, etc., can solve the problem of difficult to take into account the coupling relationship of subsystems, difficult to capture fault symptoms, large fluctuation of blast humidity, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

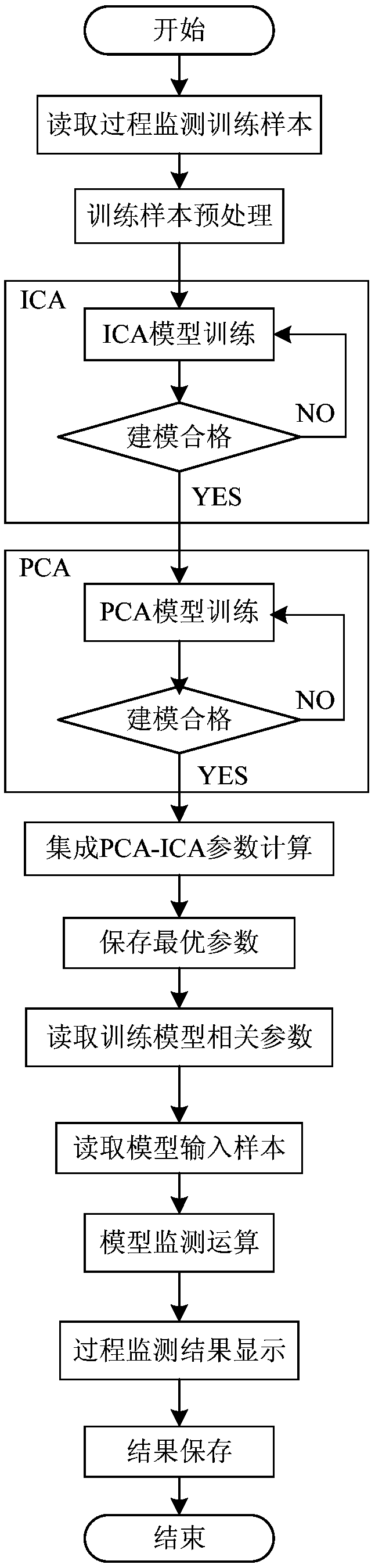

[0161] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

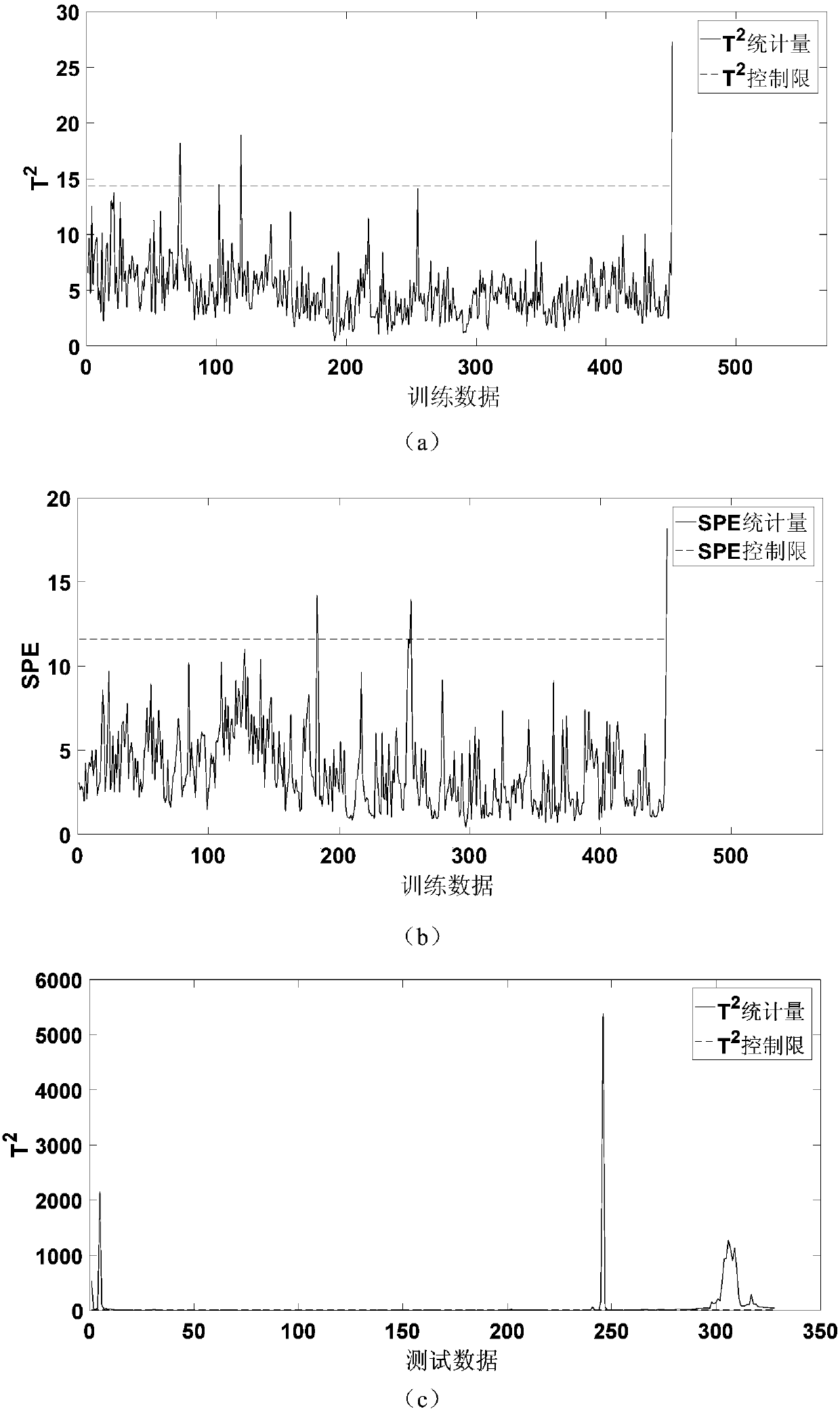

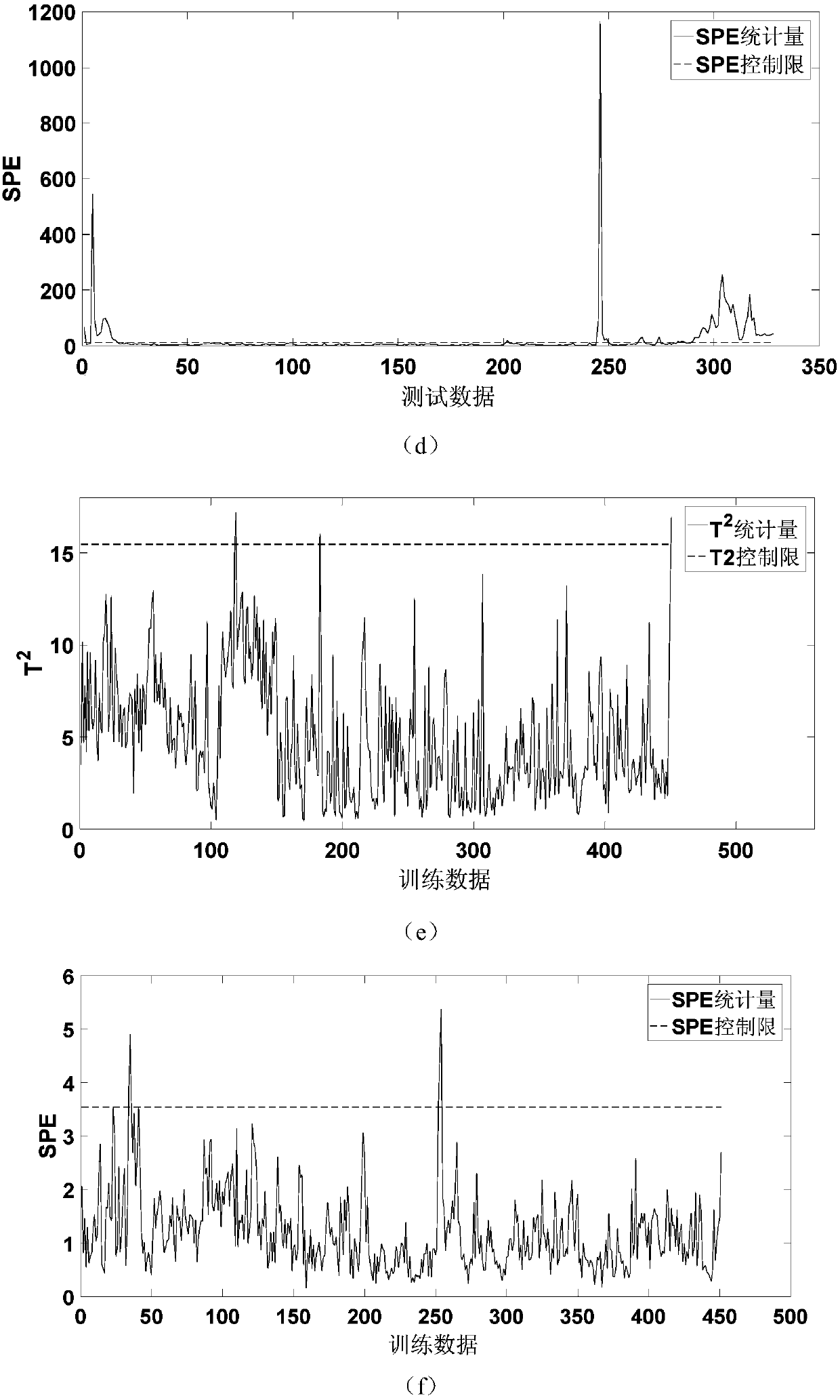

[0162] The blast furnace operating process data not only has Gaussian distribution characteristics, but also has non-Gaussian distribution characteristics. As shown in Table 1, it is the weight distribution of different process variables in the blast furnace ironmaking process.

[0163] Table 1 Weight distribution of different process variables in blast furnace ironmaking process

[0164]

[0165]

[0166] A blast furnace process monitoring and fault diagnosis method integrating PCA-ICA, which makes full use of the information contained in multivariate data and fully mines the internal structure of the data, so as to achieve the characteristics of both data variance...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com