A heat-resistant proton exchange membrane for fuel cell and a preparation method thereof

A proton exchange membrane and fuel cell technology, applied in fuel cells, circuits, electrical components, etc., can solve the problems of phosphoric acid loss, conductivity drop, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

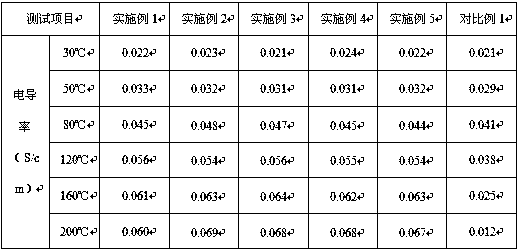

Examples

Embodiment 1

[0030] a. Dissolve organic substance A in an organic solvent, add insoluble inorganic salt B and disperse, adjust the pH to acidic and completely dissolve inorganic salt B, add additives, raise the temperature to 270°C for 4 hours, add oxidant and stir after the reaction is completed, and obtain A solution of modified organic-metal ion ligands, in which the metal ions are uniformly distributed inside the organic phase;

[0031] b. Centrifuge the solution prepared in step a, wash the centrifuge repeatedly with deionized water, then add it to an aqueous phosphoric acid solution with a mass concentration of 46%, heat at 190°C to completely evaporate the solvent, and obtain an improved phosphoric acid-doped solution. Colloidal solid material with organic phase loaded with inorganic salt;

[0032] c. The colloidal solid material obtained in step b is formed by pressing, the surface is treated with acid resistance, and dried and solidified in vacuum to obtain a heat-resistant fuel c...

Embodiment 2

[0036] a. Dissolve organic substance A in an organic solvent, add insoluble inorganic salt B and disperse, adjust the pH to acidic and completely dissolve inorganic salt B, add additives, raise the temperature to 270°C for 4 hours, add oxidant and stir after the reaction is completed, and obtain A solution of modified organic-metal ion ligands, in which the metal ions are uniformly distributed inside the organic phase;

[0037] b. Centrifuge the solution prepared in step a, wash the centrifuge repeatedly with deionized water, then add it to an aqueous phosphoric acid solution with a mass concentration of 40%, and heat at 170°C to completely evaporate the solvent to obtain an improved phosphoric acid-doped solution. Colloidal solid material with organic phase loaded with inorganic salt;

[0038] c. The colloidal solid material obtained in step b is formed by pressing, the surface is acid-resistant treated, and vacuum-dried and solidified to obtain a heat-resistant fuel cell pro...

Embodiment 3

[0042] a. Dissolve organic substance A in an organic solvent, add insoluble inorganic salt B and disperse, adjust the pH to acidic and completely dissolve inorganic salt B, add additives, raise the temperature to 270°C for 4 hours, add oxidant and stir after the reaction is completed, and obtain A solution of modified organic-metal ion ligands, in which the metal ions are uniformly distributed inside the organic phase;

[0043] b. Centrifuge the solution prepared in step a, wash the centrifuge repeatedly with deionized water, then add it to an aqueous phosphoric acid solution with a mass concentration of 50%, and heat at 200°C to completely evaporate the solvent to obtain an improved phosphoric acid-doped solution. Colloidal solid material with organic phase loaded with inorganic salt;

[0044] c. The colloidal solid material obtained in step b is formed by pressing, the surface is acid-resistant treated, and vacuum-dried and solidified to obtain a heat-resistant fuel cell pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com