Thick-film hybrid integrated heating device and preparation method for micro-atomic gas chamber

A thick-film mixing and heating device technology, which is applied in the field of micro-electromechanical systems, can solve the problems of large temperature distribution gradient, small power adjustment range, and poor control accuracy, and achieve the effects of convenient production, improved reliability, and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below with reference to the accompanying drawings and embodiments.

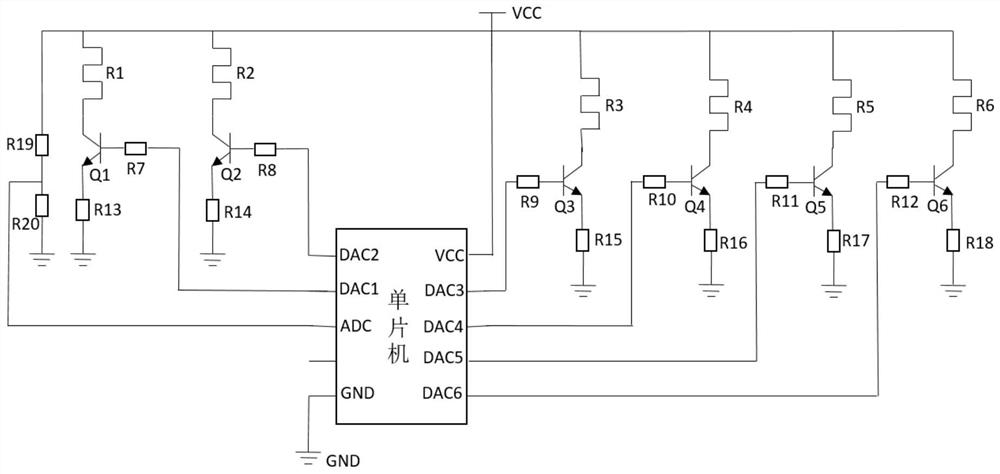

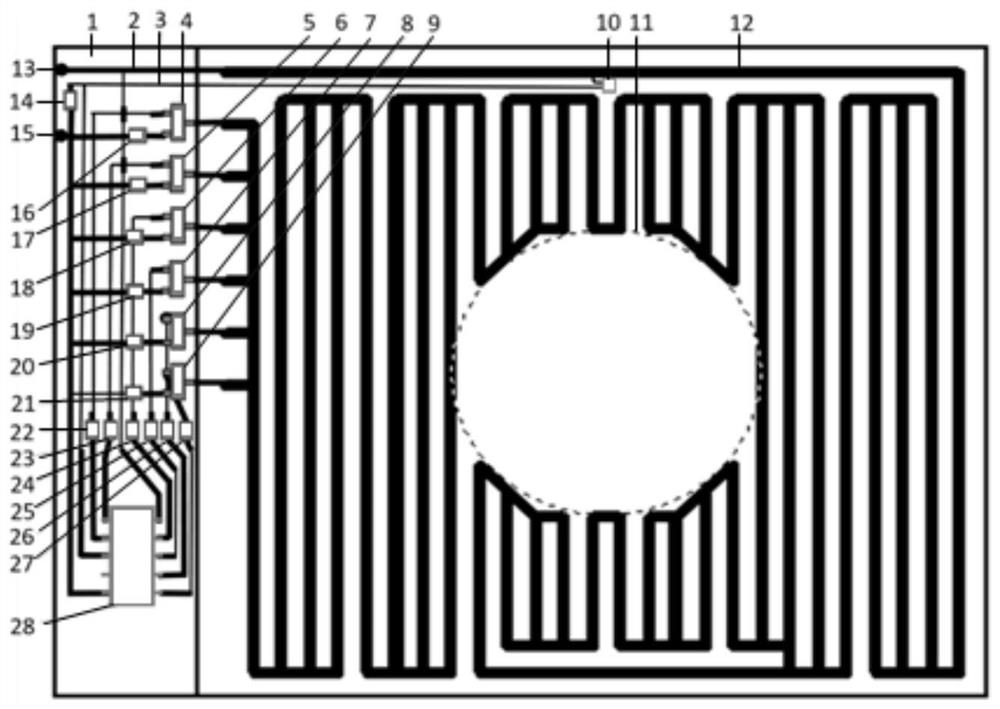

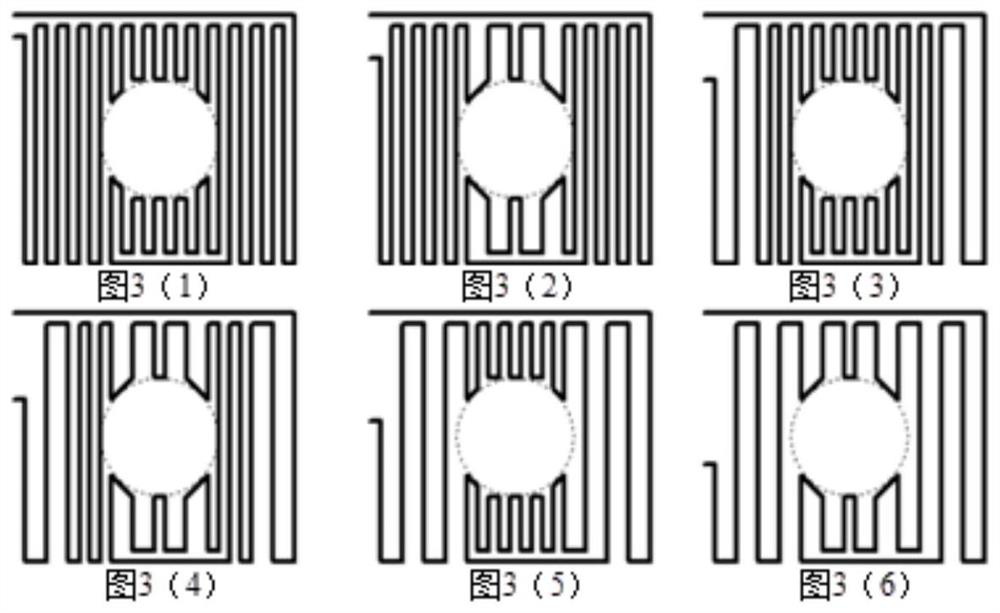

[0037]The invention provides a thick-film hybrid integrated heating device facing a micro-atomic gas chamber, comprising a heating sheet, the heating sheet includes a substrate provided with light-passing holes and 2 to 10 layers of heating resistors printed on the surface of the substrate. The upper surface of the layer heating resistor is printed with an insulating medium layer used to separate two adjacent layers of heating resistors. One end of each layer of heating resistors is connected to the power supply, and the other end is connected to the collector of a chip triode respectively. The emitters are grounded respectively through current limiting resistors, and the bases of the chip transistors are respectively connected to the digital-to-analog conversion port of the single-chip microcomputer through the series resistance, and the analog-to-digital...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com