Valve pistol for a high-pressure cleaning device

A high-pressure cleaning and valve gun technology, applied in the direction of liquid cleaning methods, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of unfavorable roughness, damage to the sealing ring, damage to the sealing ring, etc., and achieve low cost, Avoid Gap Squeeze Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

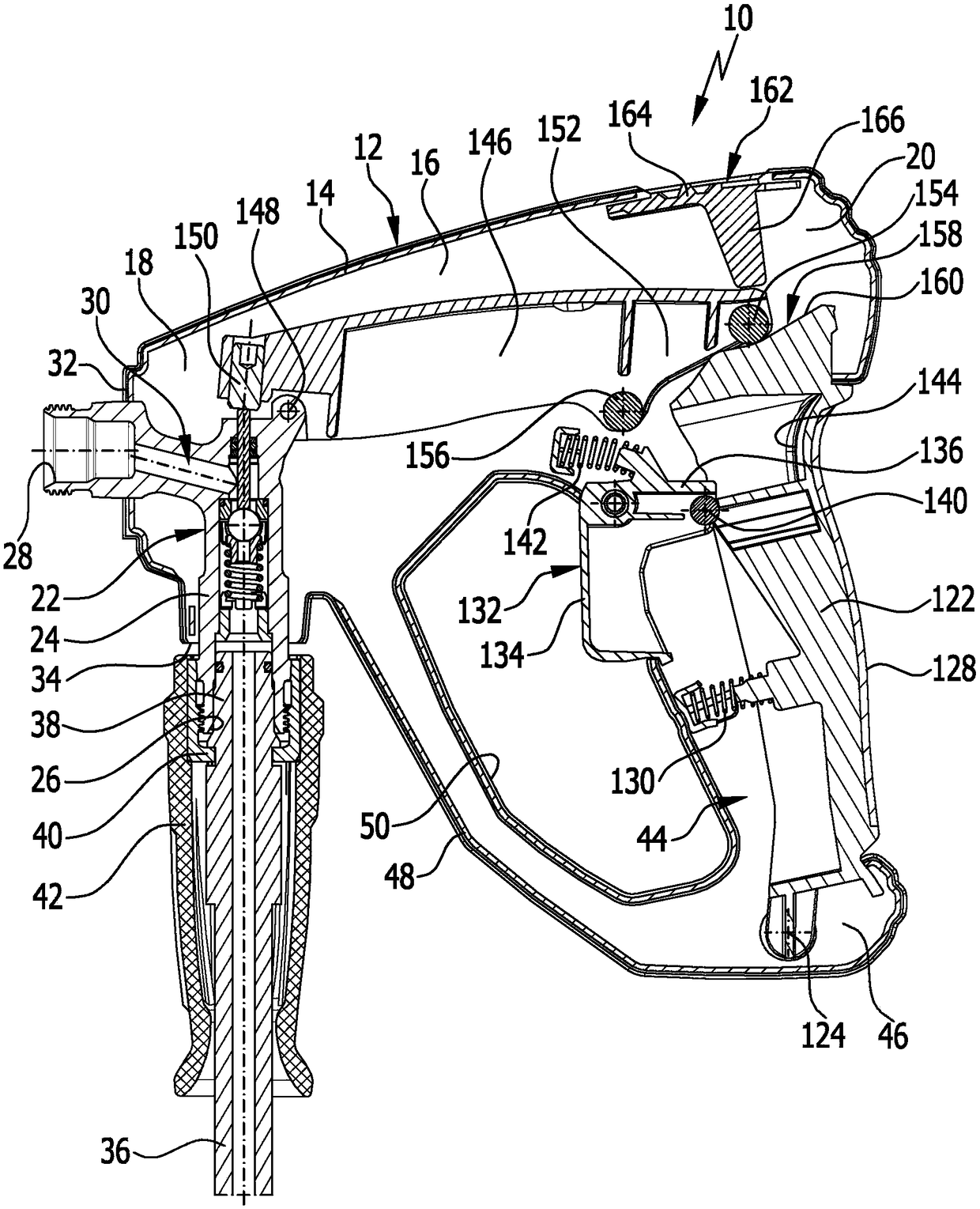

[0036] exist figure 1 An advantageous embodiment of the valve gun according to the invention is schematically shown in FIG. 1 and is generally assigned the reference numeral 10 . The valve gun 10 comprises a gun housing 12 which is formed in a conventional manner from a first housing half 14 and a second housing half, not shown in the figures. The gun housing 12 has a central housing area 16 which is arranged between a front housing area 18 and a rear housing area 20 .

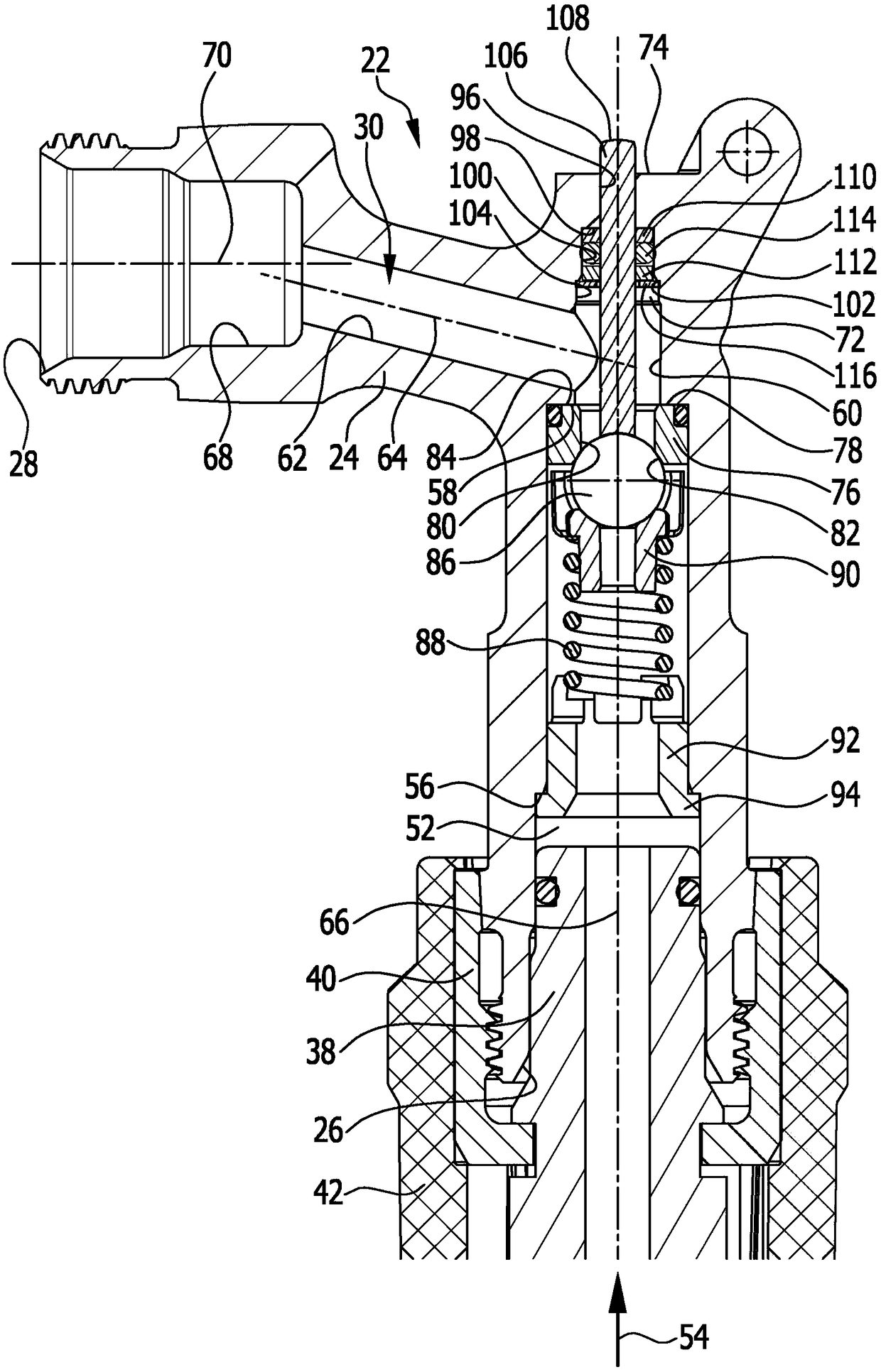

[0037] The front housing region 18 accommodates a valve 22 which has a valve housing 24 . The valve housing 24 has an inlet 26 and an outlet 28 which are in flow connection with one another via a through-channel 30 . In the embodiment shown, the outlet 28 protrudes from the front side 32 of the gun housing 12 . A nozzle can, for example, be connected to the outlet 28 . In the embodiment shown, the inlet 26 protrudes from the underside 34 of the gun housing 12 . In the embodiment shown, a pressure hose 36 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com