A column dismantling machine

A cylinder dismantling machine and column technology, which is applied in the direction of assembly machines, metal processing, metal processing equipment, etc., can solve the problems of expensive rework costs, equipment performance that cannot meet full specifications and multiple structures, and poor manufacturability, etc., to achieve improved The effect of increasing the ability and scope, avoiding rigid interference, and having many structural forms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with accompanying drawing.

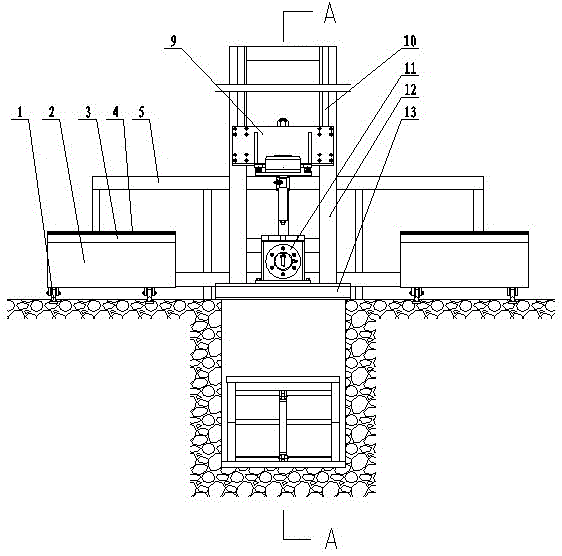

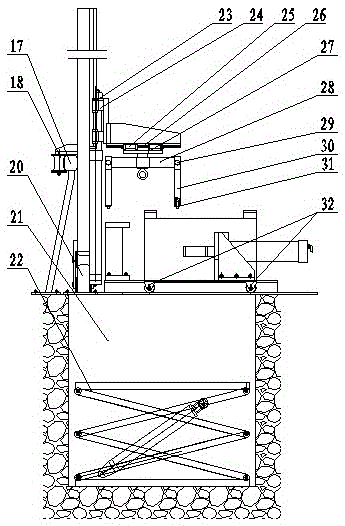

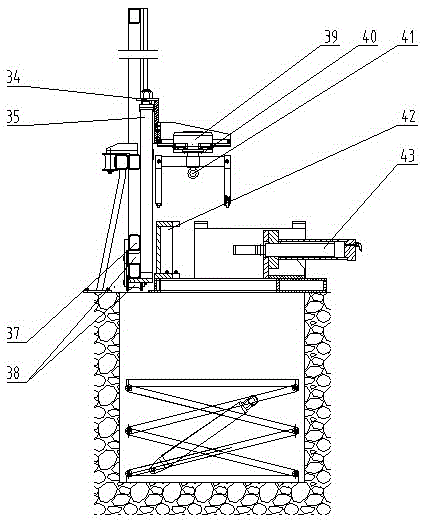

[0013] like Figure 1 to Figure 4 As shown, the column dismantling machine of the present invention includes a mobile workbench 2, a sliding frame 12, a hydraulic lifting frame 9, a rotating system 40 and a clamping device 11; 22. It is used to change the height of the groove bottom to meet the placement of workpieces of different lengths; a base 13 is installed above the ground groove 21, and the base 13 has a through hole connected to the ground groove 21, and the clamping device 11 is fixed on it; the ground groove 21 Parallel pre-buried track 1 on the ground plane on both sides, on track 1 is placed mobile worktable 2, and mobile workbench 2 passes through scroll wheel Move, meet the placement of workpieces of different lengths by moving back and forth; place a ground rail 20 on one side of the vertical groove 21, install at least one sliding rack 12 on the ground rai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com