Cleaning coke deposits from process equipment

A process equipment and a technology for removing carbon deposits. It is used in the cleaning of non-rotating equipment, mechanical equipment, lighting and heating equipment. It can solve the problems of time-consuming and uneconomical water spraying.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

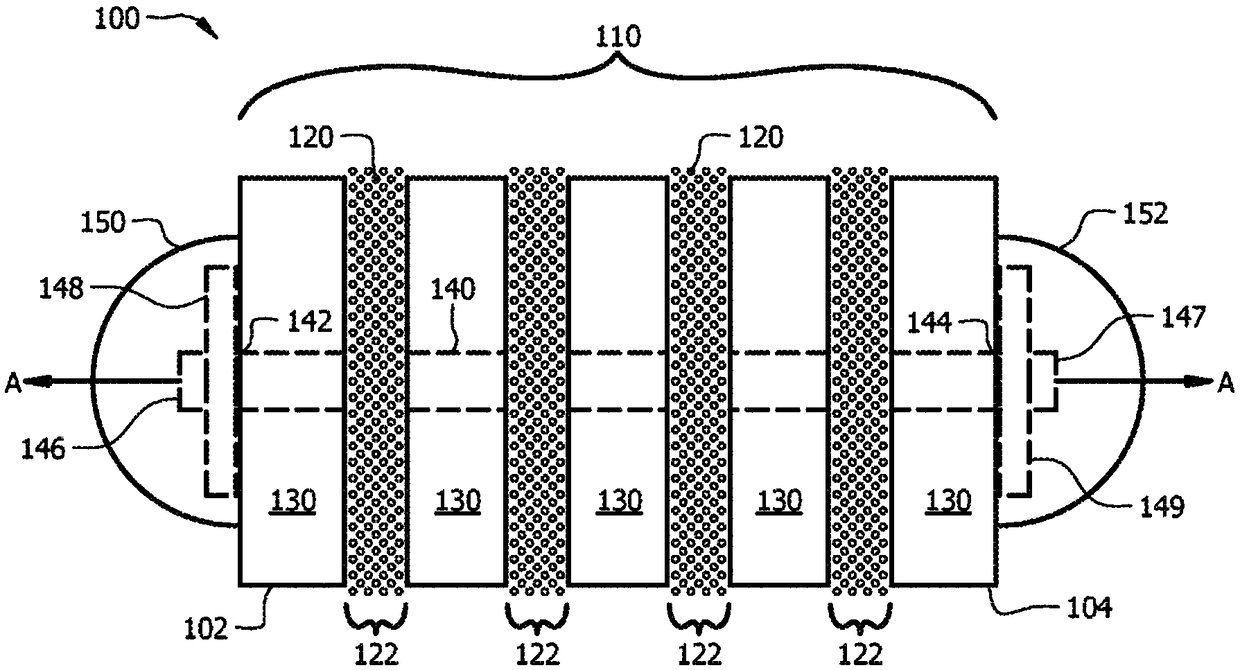

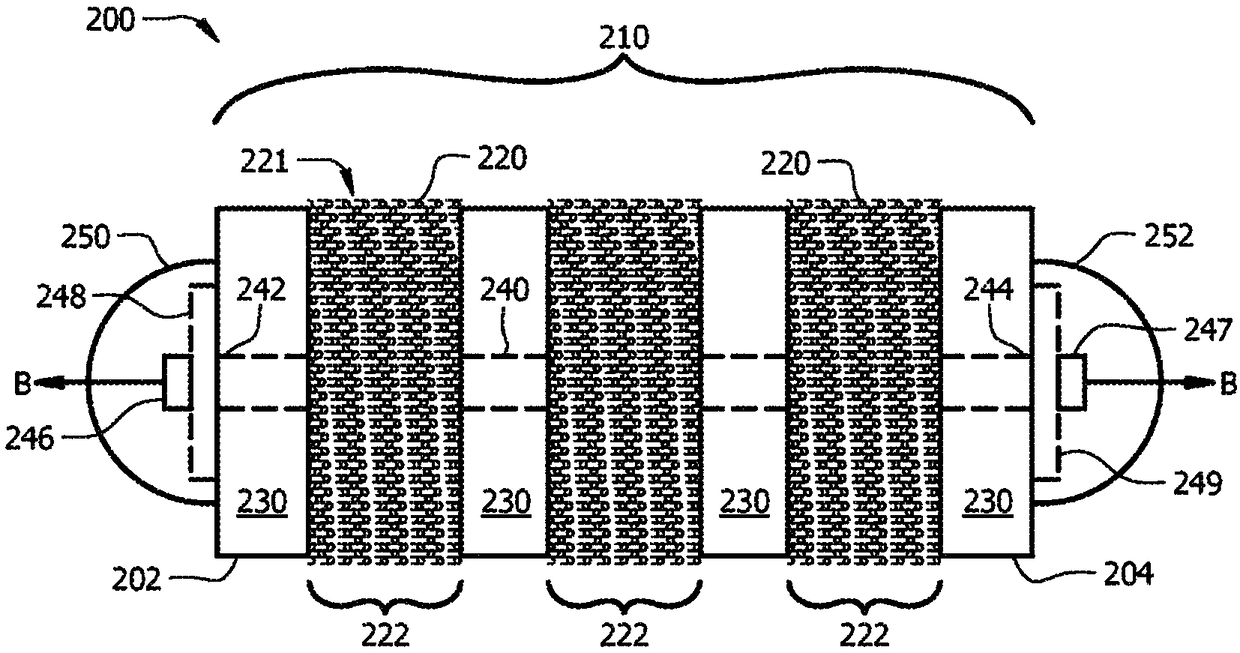

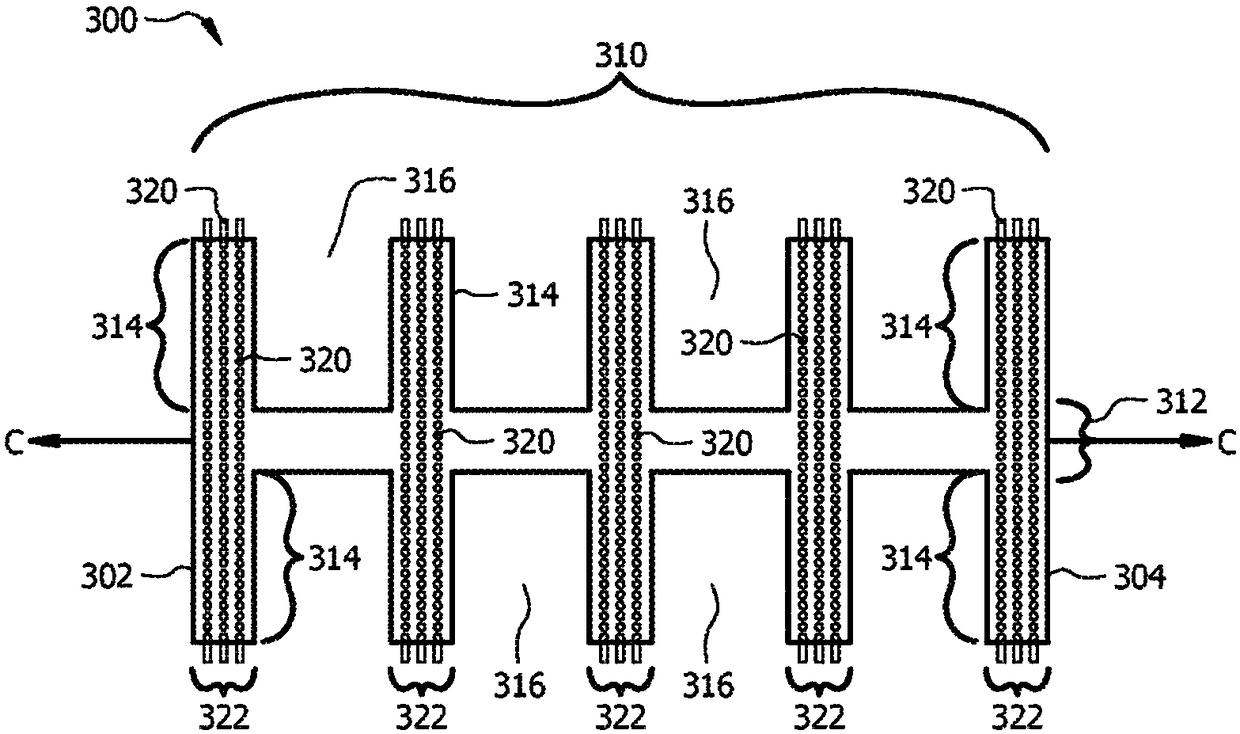

[0015] Disclosed herein are aspects of one or more flexible pigs for removing one or more carbon deposits (e.g., coke billets) from one or more interior surfaces of process equipment and methods of using the same .

[0016] Reference herein to "process equipment" refers to any hydrocarbon process equipment that is exposed to reactions and / or conditions that form carbon deposits on interior surfaces to which the interior surfaces are exposed. For simplicity and clarity, as an aspect of the disclosed process equipment, a furnace tube with a stannide layer as a protective layer is discussed herein for use in a catalytic reforming process.

[0017] As used herein, "interior surface" refers to one or more interior surfaces of process equipment made of metal (e.g., carbon steel, mild steel, alloy steel, stainless steel, austenitic stainless steel, or combinations thereof), and Refers to one or more interior surfaces of process equipment having a protective metal layer thereon, such...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com