Glazing comprising a clip-on profiled bead for a clip-on cover part

A technology for glass windows and profiles, applied in windshields, glass/slag layered products, windows, etc., to achieve the effect of easy manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

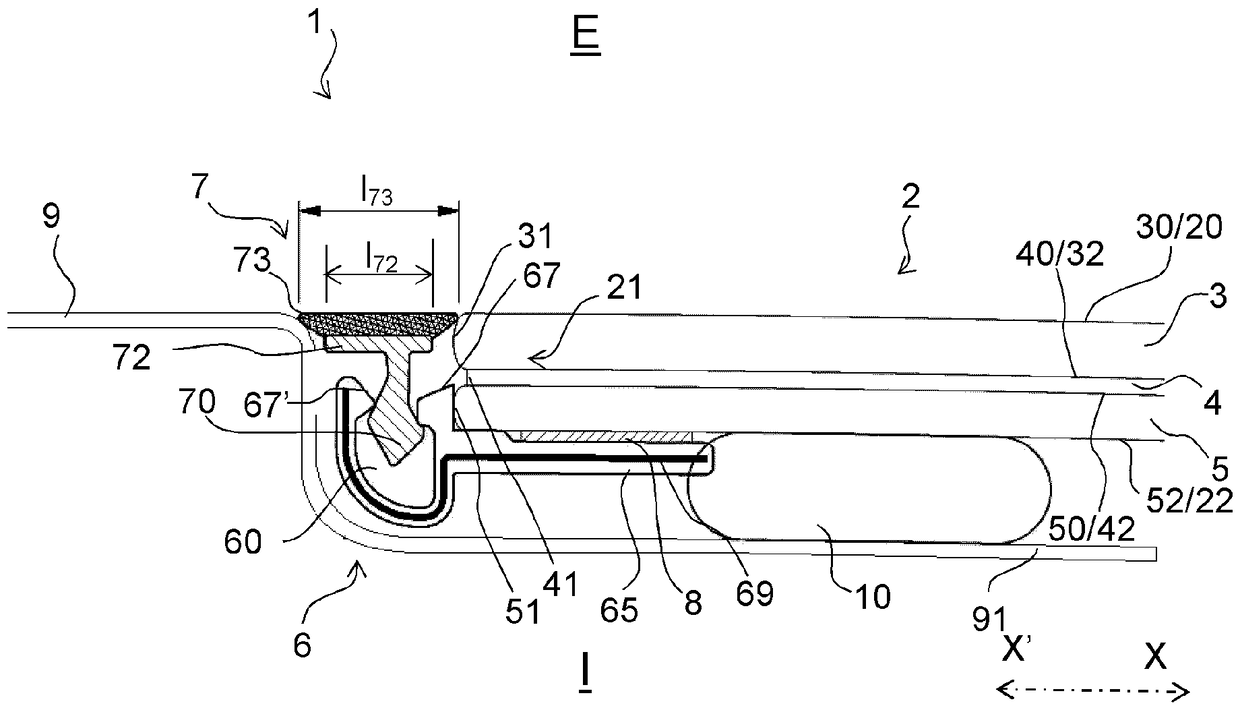

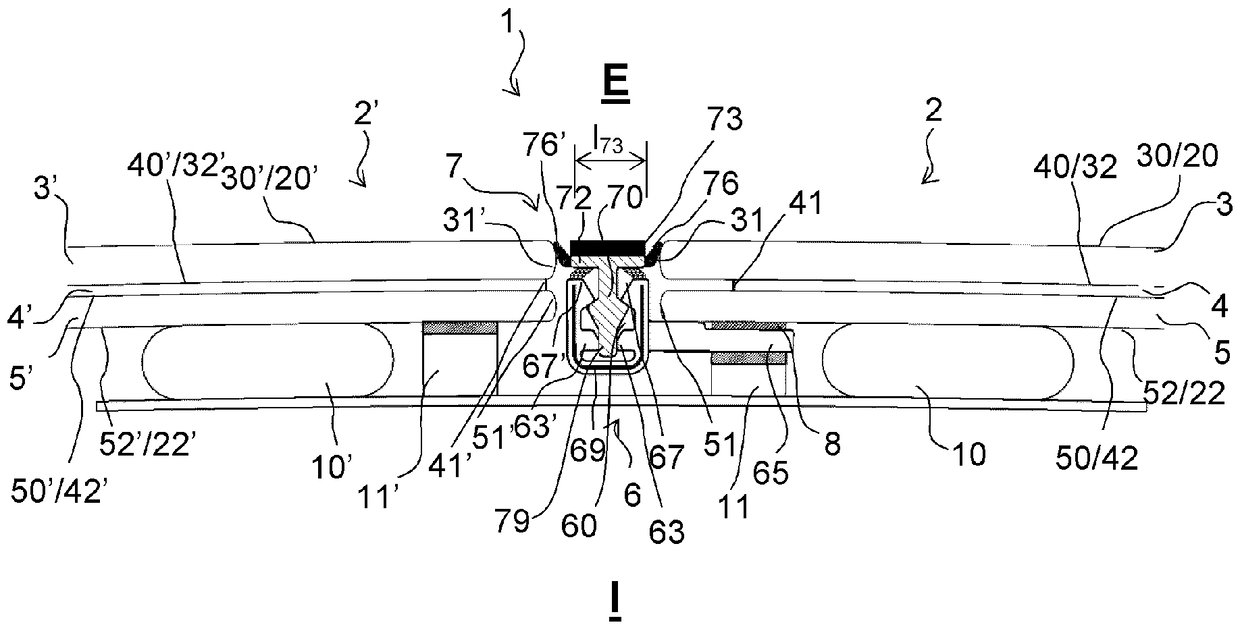

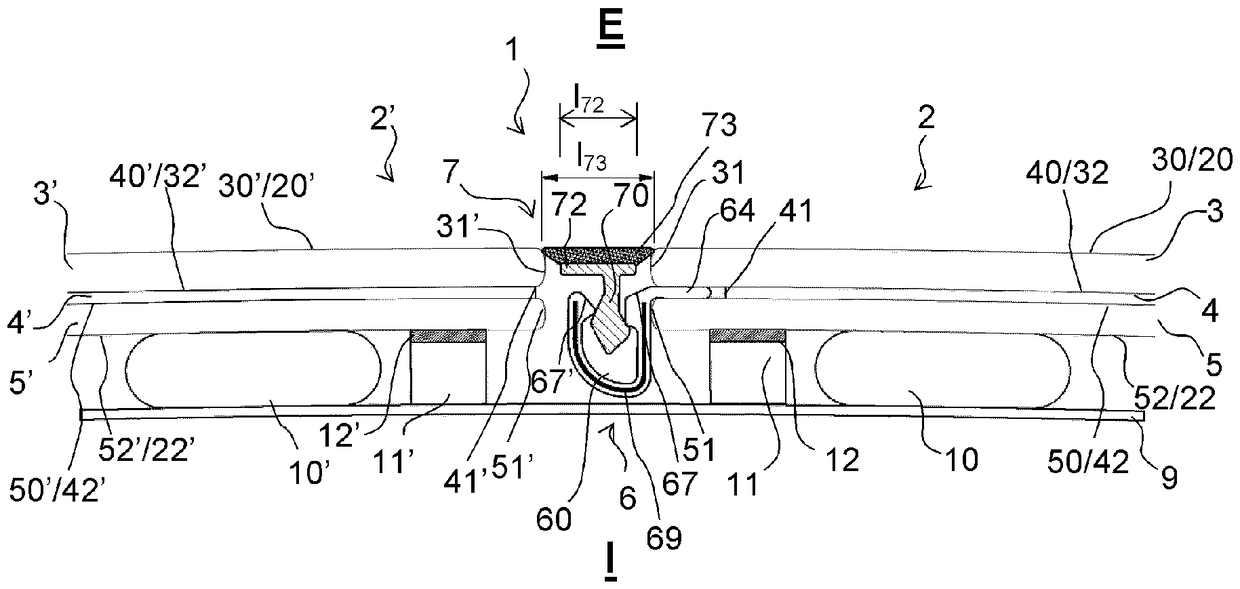

[0104] The present invention relates to glazing 1, as in Figure 1 to Figure 7 Visible in part, the glazing 1 comprises at least one pane 2 in a single sheet or laminated.

[0105] By way of example, the invention is described in the context of an application as a vehicle glazing enabling a separation between an exterior space E outside the vehicle and an interior space I inside the vehicle. The terms "outer" and "inner" are therefore considered with respect to the outer space E and the inner space I, respectively.

[0106] The glazing 2 thus has an outer face 20 oriented towards the outer space E, an inner face 22 oriented towards the inner space I and a peripheral side 21 located between these two faces.

[0107] In particular, the present invention is described as a fixed sunroof applied to a vehicle, and therefore, the drawing is a cross-sectional view along a perpendicular line of a glass window 1 installed, pasted in a window opening of a vehicle body.

[0108] for F...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com