Method for producing sic substrate provided with graphene precursor and method for surface treating sic substrate

一种表面处理、石墨烯的技术,应用在石墨烯、单层石墨烯、处理后等方向,能够解决未描述SiC基板与石墨烯片结构等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

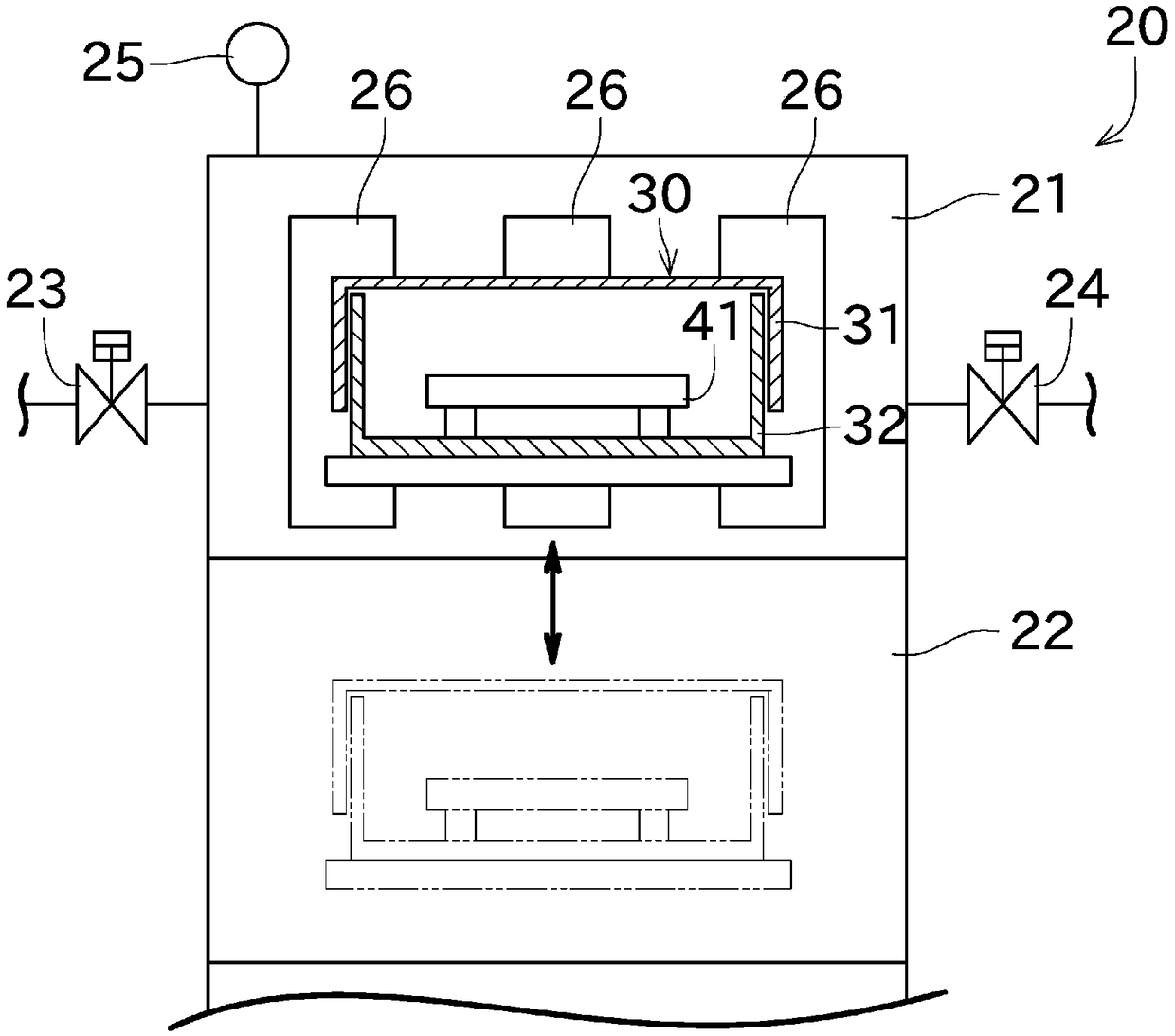

[0062] Hereinafter, embodiments of the present invention will be described with reference to the drawings. First, refer to figure 1 , the high-temperature vacuum furnace 20 used for the heat treatment of this embodiment will be described.

[0063] like figure 1 As shown, a high-temperature vacuum furnace (heating device) 20 includes a main heating chamber 21 and a preheating chamber 22 . The main heating chamber 21 is capable of heating a SiC substrate 41 (single crystal SiC substrate) having at least a surface made of single crystal SiC to a temperature of 1000° C. or higher and 2300° C. or lower. The preheating chamber 22 is a space for preheating before heating the SiC substrate 41 in the main heating chamber 21 .

[0064] A vacuum forming valve 23 , an inert gas injection valve 24 and a vacuum gauge 25 are connected to the main heating chamber 21 . The vacuum forming valve 23 can adjust the degree of vacuum of the main heating chamber 21 . The inert gas injection valv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| etching rate | aaaaa | aaaaa |

| etching rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com