High heat-shrinkable polyamide fiber and blended yarn and fabric using the polyamide fiber

A polyamide fiber, shrinkage technology, applied in the direction of single-component polyamide rayon, fabric, knitting, etc., can solve the problems of high Young's modulus, hard hand feeling, etc., and achieve the effect of excellent shrinkage characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

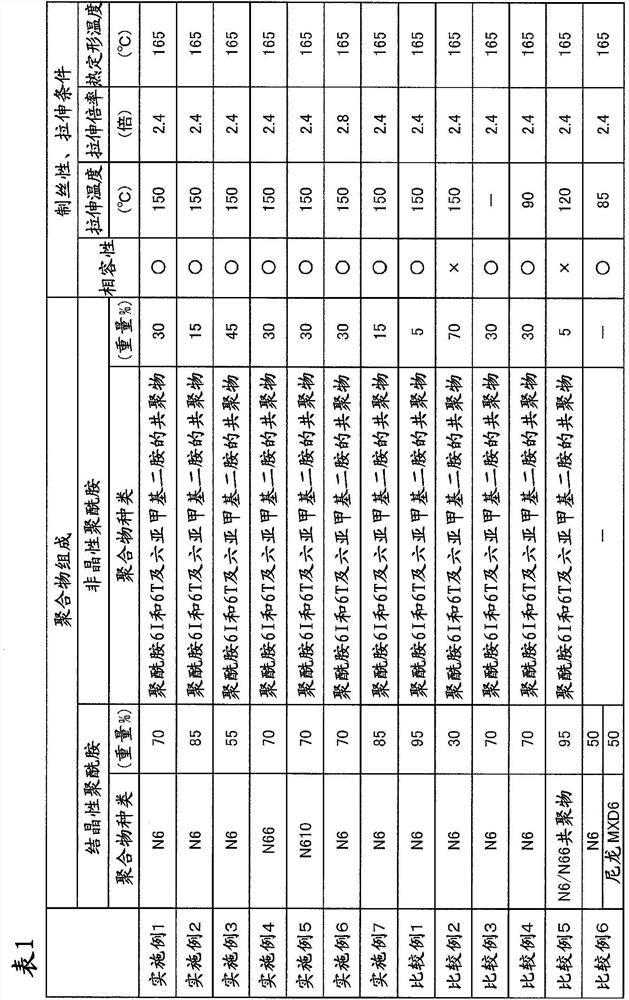

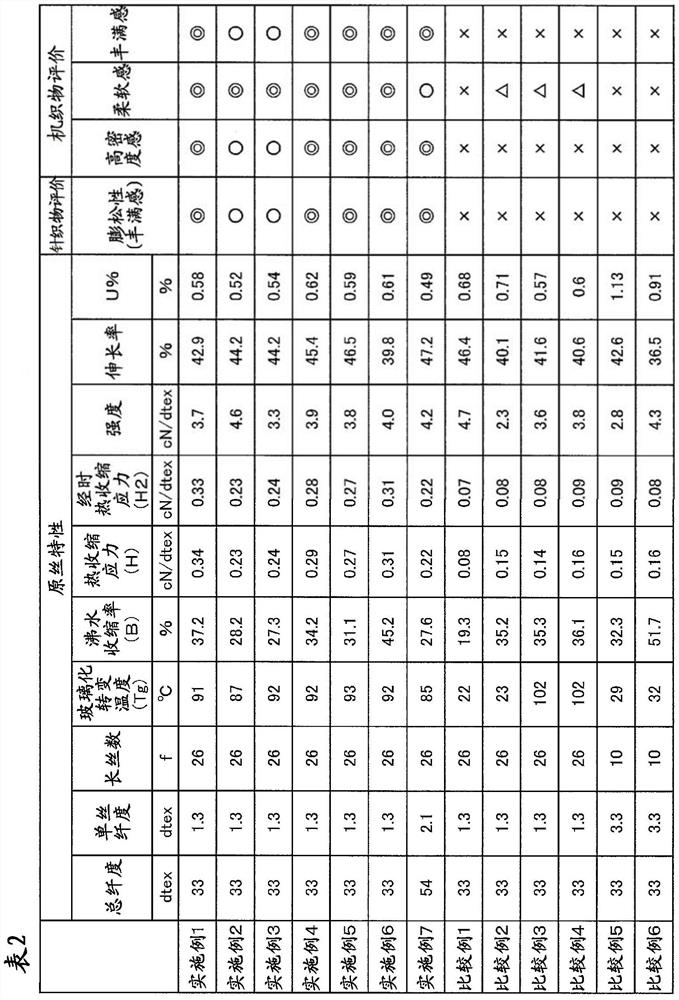

Embodiment 1

[0116] Polycaprolactam (N6) (relative viscosity ηr: 2.62, melting point 222°C) as a crystalline polyamide and isophthalic acid / terephthalic acid as a non-crystalline polyamide at a copolymerization ratio of 7 / 3 Polycondensate of phthalic acid (6I) / terephthalic acid (6T) / hexamethylenediamine (relative viscosity ηr: 2.10), the weight ratio of crystalline polyamide / non-crystalline polyamide is 70 / 30 Melt-kneading was carried out at 265° C. using a single-screw extruder, and melt discharge was carried out using a spinneret having 26 circular discharge holes (spinning temperature: 265° C.). After being melted and discharged, the filaments are cooled, oiled, and interwoven, and then drawn with the first godet roller (stretching temperature: 150°C) at 1500m / min, and then stretched to 2.4 times and then heat-set at 165°C. A polyamide yarn of 33 dtex26 filaments (relative viscosity ηr: 2.46, glass transition temperature (Tg): 91° C.) was obtained at a winding speed of 3500 m / min.

Embodiment 2

[0118] Except that the weight ratio of crystalline polyamide / non-crystalline polyamide was 85 / 15, spinning was carried out in the same manner as in Example 1 to obtain polyamide filaments of 33 dtex26 filaments (relative viscosity ηr: 2.54, Glass transition temperature (Tg): 87°C).

Embodiment 3

[0120] Except that the weight ratio of crystalline polyamide / non-crystalline polyamide was 55 / 45, spinning was carried out in the same manner as in Example 1 to obtain polyamide filaments of 33 dtex26 filaments (relative viscosity ηr: 2.39, Glass transition temperature (Tg): 92°C).

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com