Camshaft adjusting system with means for catching hydraulic fluid draining from a valve in order to directly recirculate the fluid into the camshaft adjuster

A technology of camshaft adjuster and camshaft adjustment, which is applied in fluid pressure actuators, valve devices, engine components, etc., and can solve problems such as high inertia

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

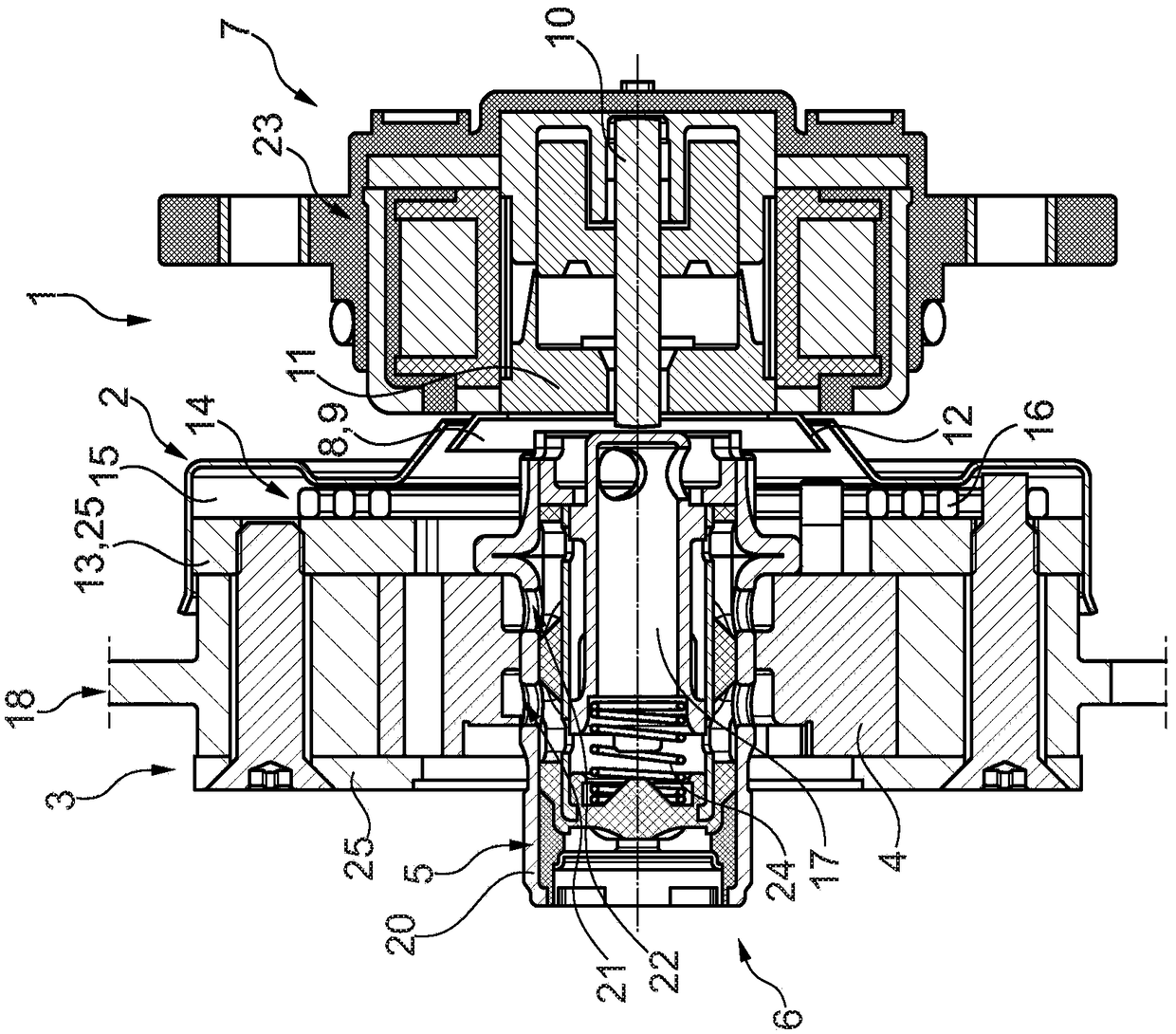

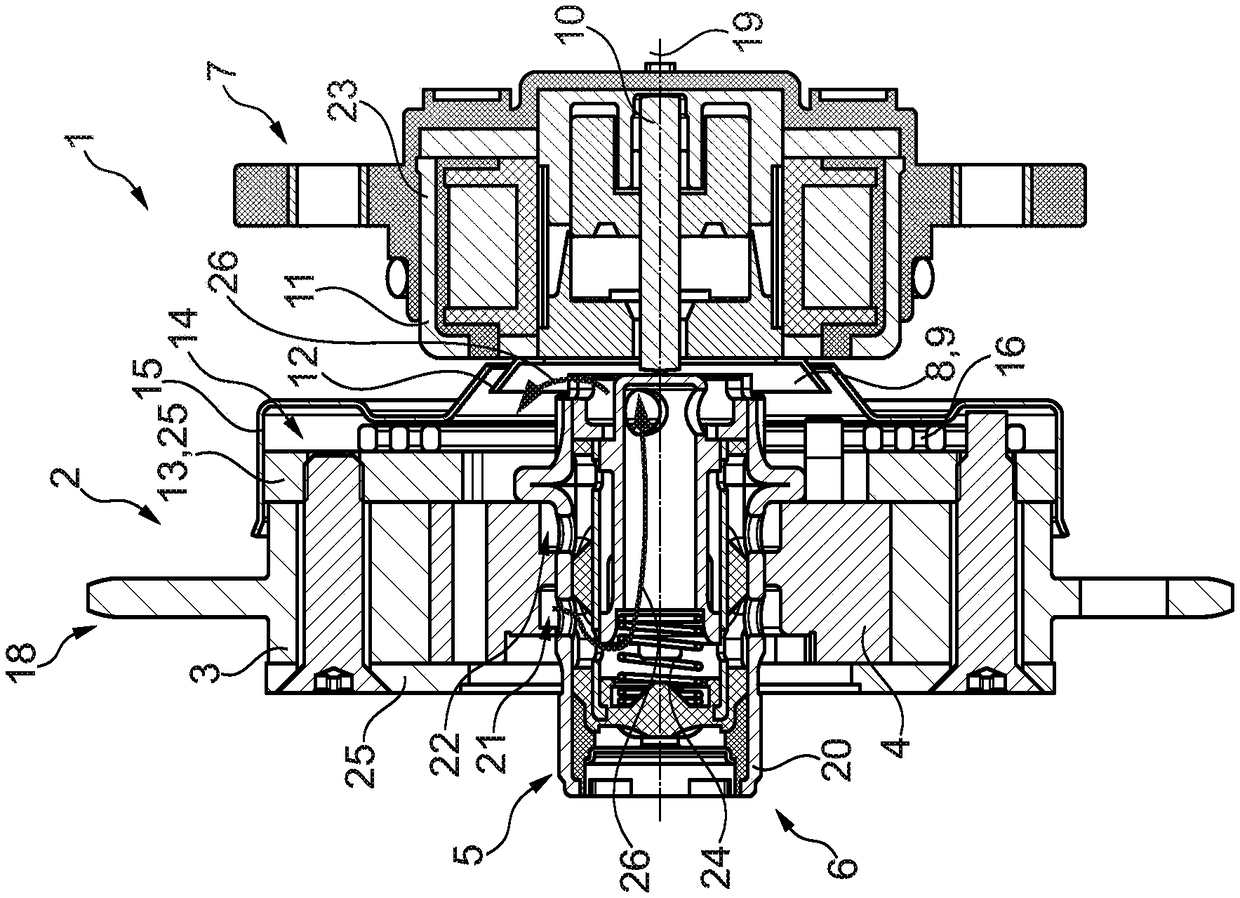

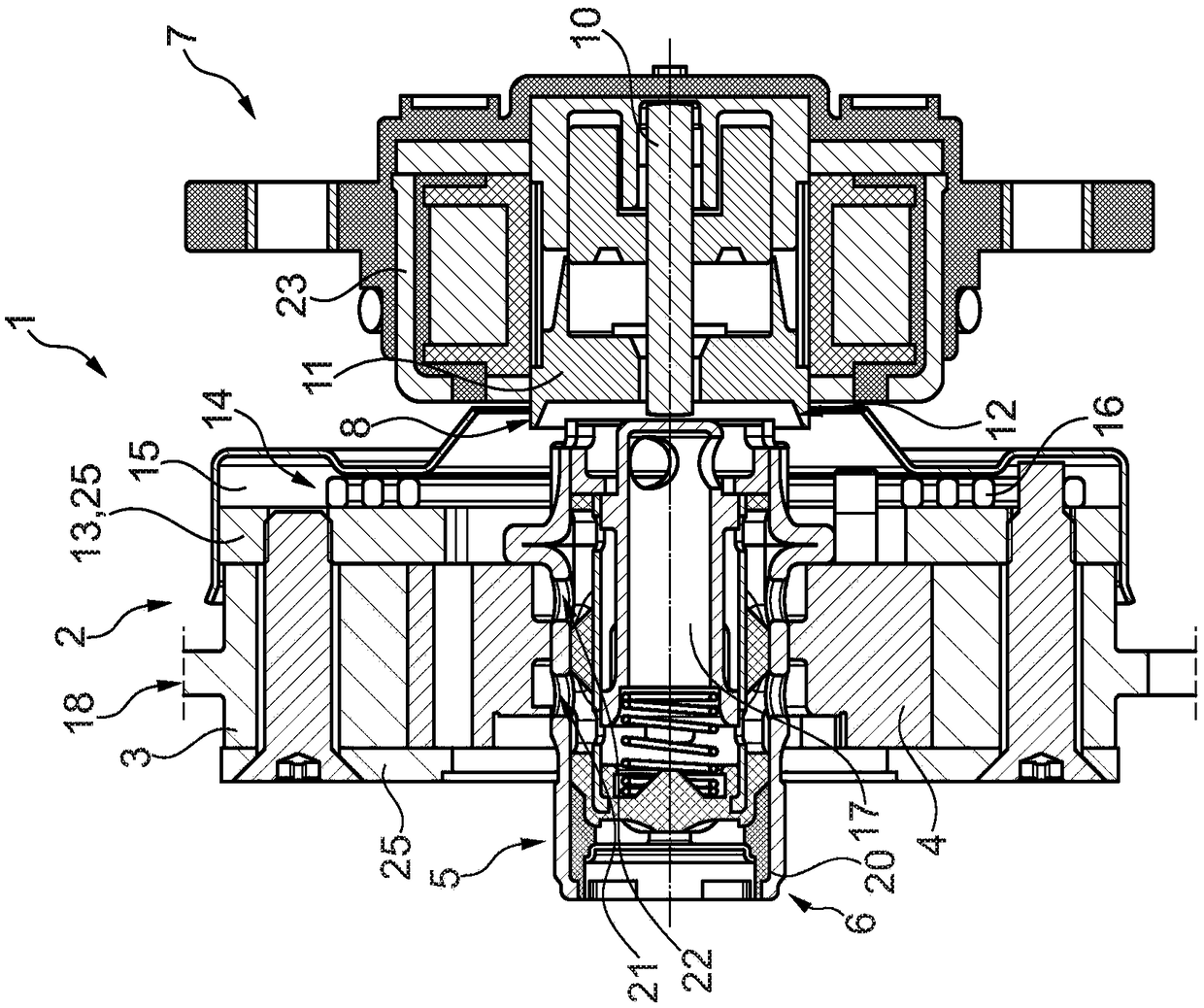

[0027] exist figure 1 A camshaft adjustment system 1 according to a first preferred embodiment is shown schematically in . The camshaft adjustment system 1 is formed from a camshaft adjuster 2 and an actuator 7 acting on the camshaft adjuster 2 in an adjusting manner.

[0028] The camshaft adjuster 2 is basically embodied here as a hydraulic camshaft adjuster 2 . The camshaft adjuster 2 is designed according to the vane unit type / vane unit design. Correspondingly, camshaft adjuster 2 has an outer component referred to as stator 3 . The stator 3 is connected in a rotationally fixed manner to the traction means, ie the chain, of the traction means transmission via the traction means receptacle 18 during operation of the internal combustion engine, the traction means being connected in a conventional manner to the crankshaft of the internal combustion engine in a non-rotatable manner. The traction means receptacle 18 is also referred to as a drive wheel.

[0029] On its radia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com