Method for operating an internal combustion engine, device for the open-loop and closed-loop control of an internal combustion engine, injection system, and internal combustion engine

A technology of injection system and internal combustion engine, applied in charging system, engine control, fuel injection control, etc., to save storage space, improve the possibility of influence, and save computing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

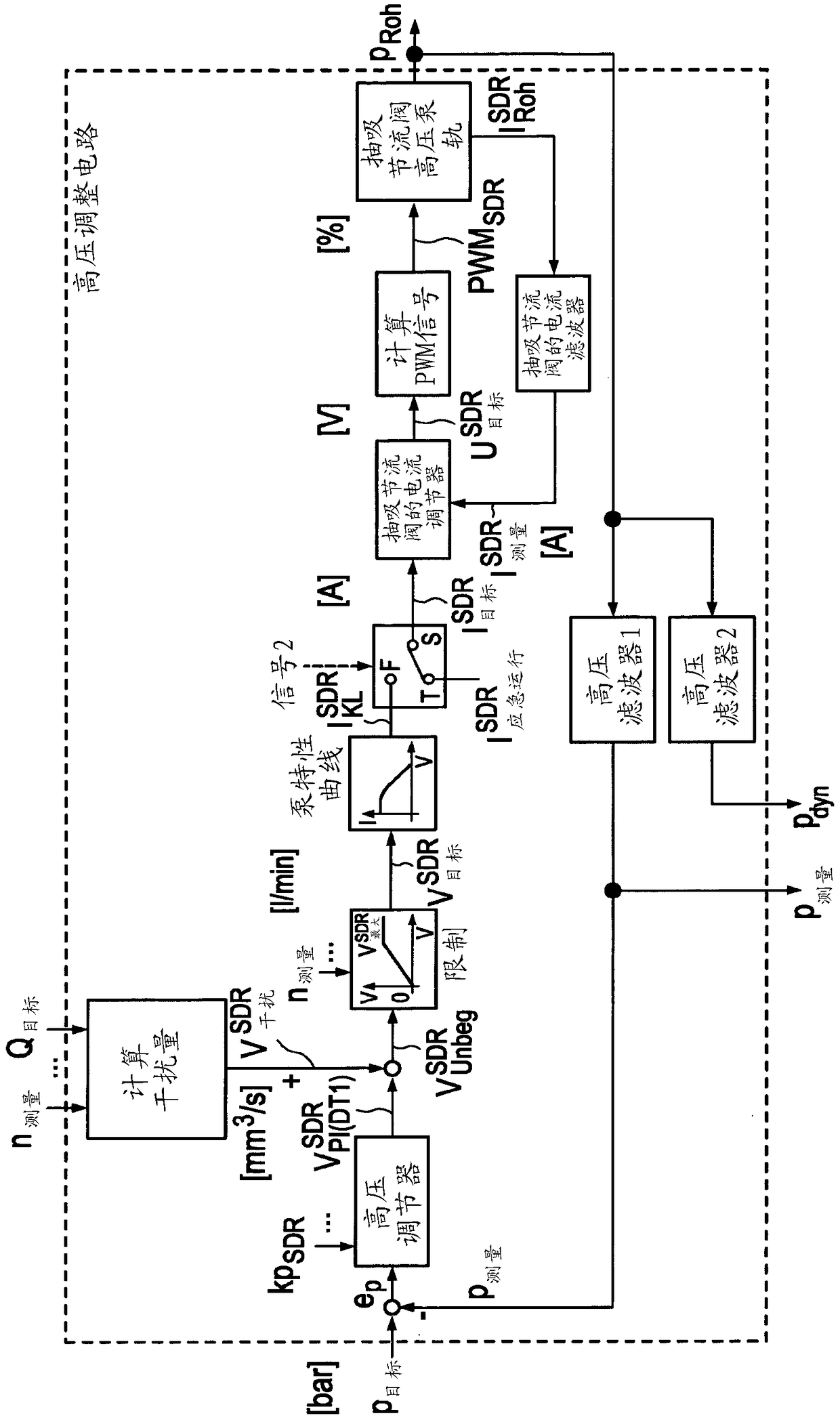

[0062] figure 1 A device corresponding to the prior art as described in DE 10 2014 213 648 B3 is shown. The internal combustion engine 1 has an injection system 3 here. The injection system 3 is preferably configured as a common rail injection system. It has a low-pressure pump 5 for delivering fuel from the fuel container 7, a suction throttle valve 9 on the adjustable low-pressure side that affects the fuel-volume flow to the high-pressure pump 11, and Under pressure, a high-pressure pump 11 that delivers fuel to the high-pressure accumulator 13, a high-pressure accumulator 13 for storing fuel, and preferably a plurality of injectors 15 for injecting fuel into the combustion chamber 16 of the internal combustion engine 1 . Alternatively, it is possible that the injection system 3 is also provided with a single reservoir, wherein, for example, a single reservoir 17 is integrated in the injector 15 as an additional buffer space. In the embodiment shown here, a pressure regu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com