Active matrix substrate, method for producing same, and display device

An active matrix and manufacturing method technology, applied in semiconductor/solid-state device manufacturing, optics, instruments, etc., can solve problems such as poor contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

[0073]

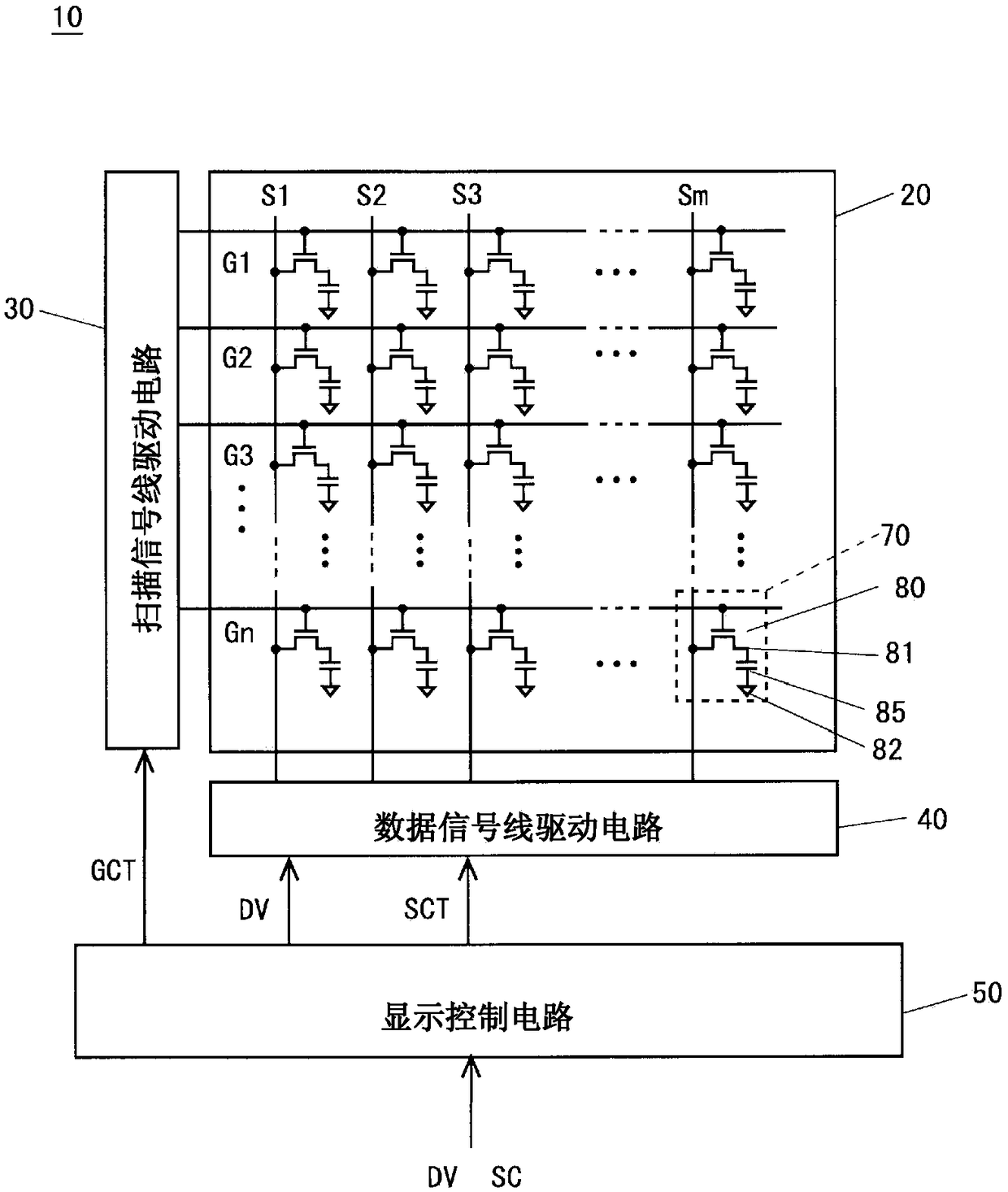

[0074] figure 1 It is a block diagram showing the configuration of a liquid crystal display device 10 including the active matrix substrate of the first embodiment. Such as figure 1 As shown, the liquid crystal display device 10 includes a liquid crystal panel 20, a scanning signal line driving circuit 30, a data signal line driving circuit 40, and a display control circuit 50. As will be described later, the liquid crystal panel 20 combines an active matrix substrate and a color filter The substrates are bonded together.

[0075] Formed on the liquid crystal panel 20 are: m data signal lines S1 to Sm; n scanning signal lines G1 to Gn; (m×n) pixel forming portions 70 . Each pixel forming portion 70 includes: a thin film transistor (Thin Film Transistor: TFT) 80, the gate electrode of which is connected to the scanning signal lines G1-Gn passing through the corresponding intersection, and the source electrode is connected to each data signal line passing through...

no. 2 approach

[0112]

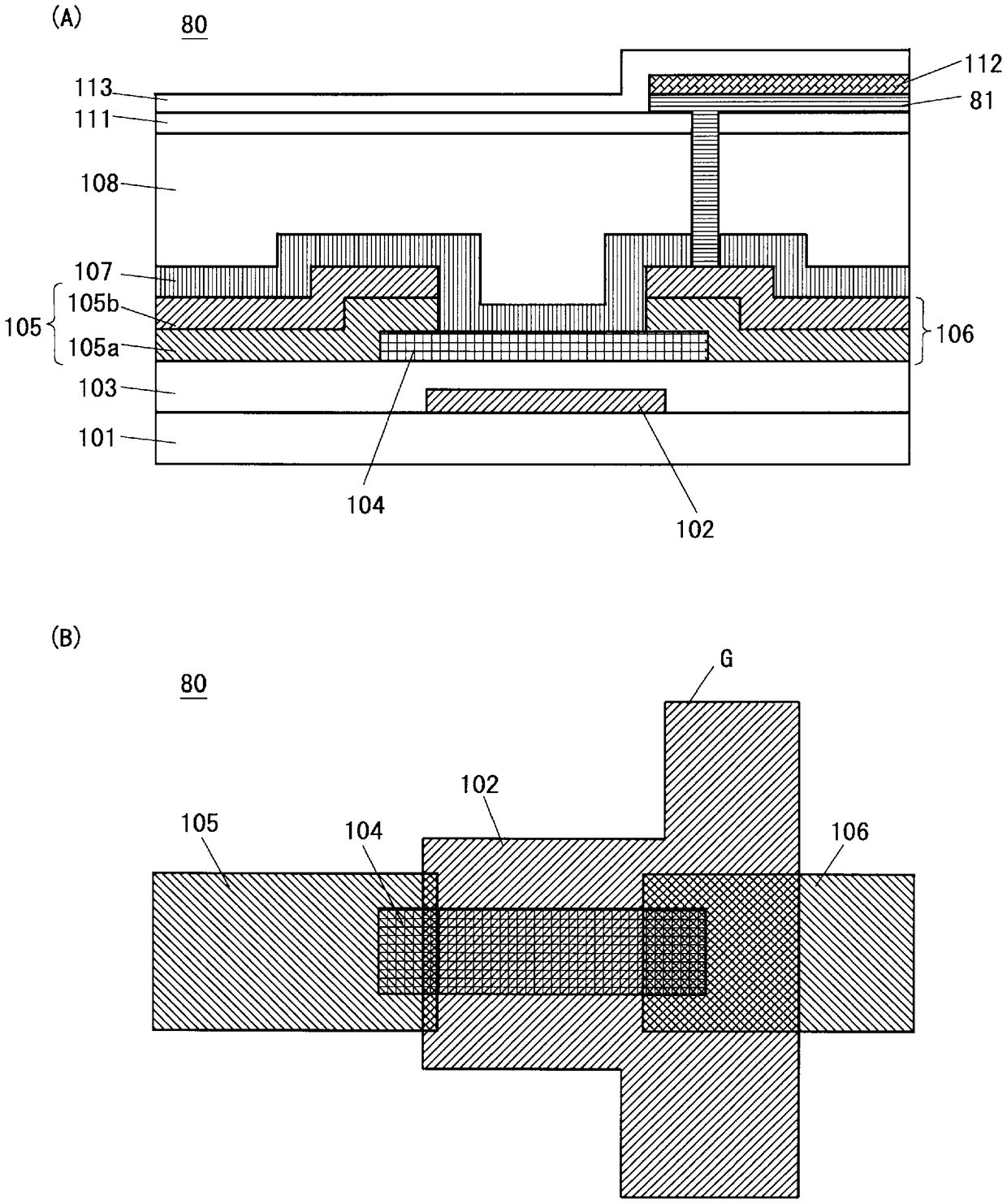

[0113] Figure 8 is a diagram showing the structure of the wiring connection structure 151 included in the active matrix substrate 10a of the second embodiment, and more specifically, Figure 8 (A) is a sectional view showing the wiring connection structure 151, Figure 8 (B) is a plan view of the wiring connection structure 151 . Such as Figure 8 (A) and Figure 8 As shown in (B), the wiring connection structure 151 of this embodiment has the same Figure 4 The wiring connection configuration 150 shown is a very similar configuration. Therefore, yes Figure 8 (A) and Figure 8 In the wiring connection structure 151 shown in (B), the same structure as the wiring connection structure 150 is denoted by the same reference numeral, and the description is abbreviate|omitted, and a different structure is demonstrated.

[0114] and Figure 4 Similarly to the case shown, an opening 103 c is formed in the gate insulating film 103 inside the contact hole 140 . The e...

no. 3 approach

[0125]

[0126] Figure 10 is a diagram showing the structure of the wiring connection structure 152 included in the active matrix substrate 10a of the third embodiment, and more specifically, Figure 10 (A) is a sectional view of the wiring connection structure 152, Figure 10 (B) is a plan view of the wiring connection structure 152 . Such as Figure 10 (A) and Figure 10 As shown in (B), the wiring connection structure 152 of this embodiment has Figure 15 (A) and Figure 15 The conventional wiring connection structure 250 shown in (B) has a very similar structure. Therefore, yes Figure 10 (A) and Figure 10 In the wiring connection structure 152 shown in (B), the same structure as the wiring connection structure 250 is denoted by the same reference numeral, and description is abbreviate|omitted, and a different structure is demonstrated.

[0127] Such as Figure 10 (A) and Figure 10 As shown in (B), in the wiring connection structure 152 of this embodiment, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com