Large particle feed screening and air drying device

An air-drying device and large particle technology, which is applied in the direction of feed, drying gas arrangement, filter and sieve, etc., can solve the problems of independent dispersion and high energy consumption, and achieve the effect of increasing air circulation, strengthening air-drying effect, and good circulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

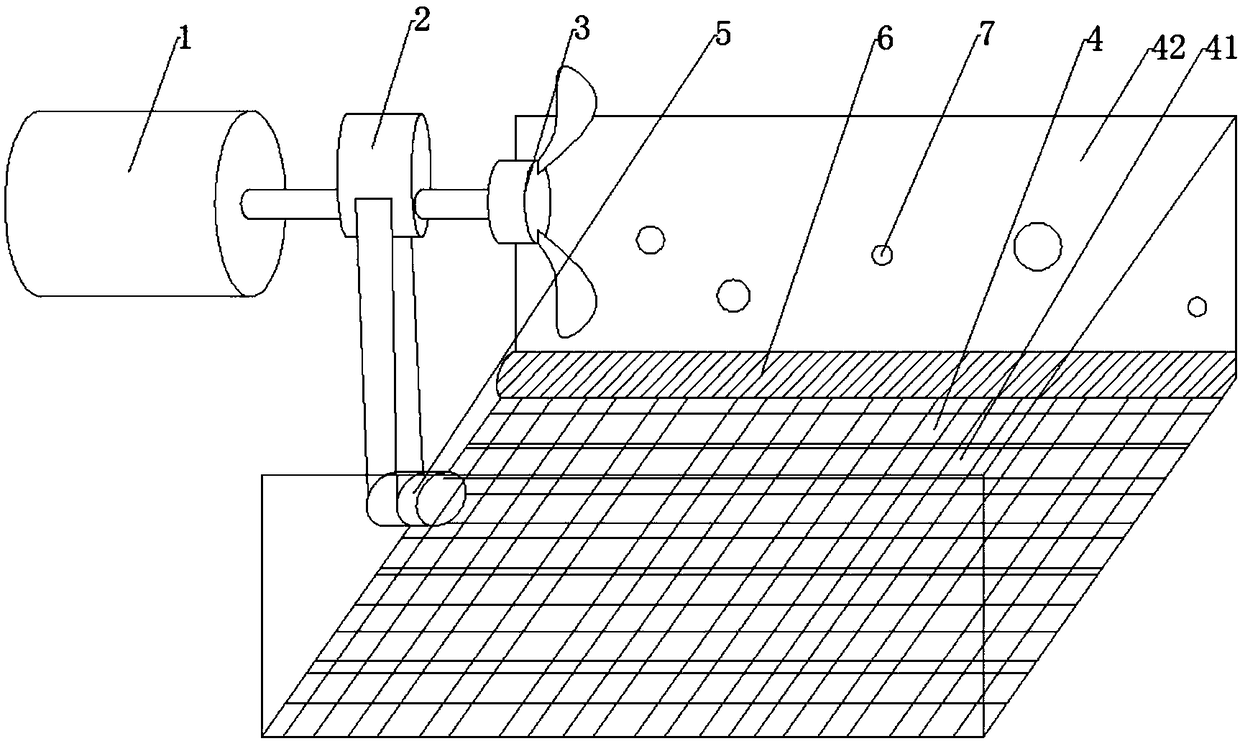

[0024] A large particle feed screening and air-drying device, comprising a mounting frame, a driving motor is fixed on the mounting frame, a fan is sleeved on the output shaft of the driving motor, the blades of the fan rotate around the output shaft of the driving motor, and the output shaft of the driving motor A cam is also set on the top, and the axis of the cam coincides with the axis of the output shaft of the drive motor; an air-drying box is installed on one side of the fan, the windward side and the top of the air-drying box are set as openings, and the bottom of the air-drying box is a screening drain plate, which is air-dried The rest of the side of the box is a partition, the partition is transparent glass, and there are many round holes on the partition; there are evenly square leak holes on the screening leak board, and the square leak holes are suitable for the particle size of the large pellet feed; One side of the bottom of the air-drying box is hinged on the m...

Embodiment 2

[0026] A large particle feed screening and air-drying device, comprising a mounting frame, a driving motor is fixed on the mounting frame, a fan is sleeved on the output shaft of the driving motor, the blades of the fan rotate around the output shaft of the driving motor, and the output shaft of the driving motor There is also a cylindrical wheel on the eccentric sleeve; there is an air-drying box on one side of the fan, the windward side and the top of the air-drying box are set as openings, the bottom of the air-drying box is a screening drain plate, and the remaining sides of the air-drying box are partitions. Transparent glass, and there are many round holes on the partition; square leak holes are uniformly opened on the screening drain plate, and the square leak holes are suitable for the particle size of large pellet feed; one side of the bottom of the air-drying box is hinged by a hinge shaft On the mounting frame, a pulley is hinged on one side of the bottom of the air-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com