Battery liquid injecting hole cleaning method and cleaning device

A technology for cleaning devices and liquid injection holes, which is applied in the direction of cleaning methods and appliances, battery pack parts, chemical instruments and methods, etc. It can solve problems such as residual electrolyte, incomplete cleaning, and affecting the welding quality of sealing nails. The effect of safe and reliable operation and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

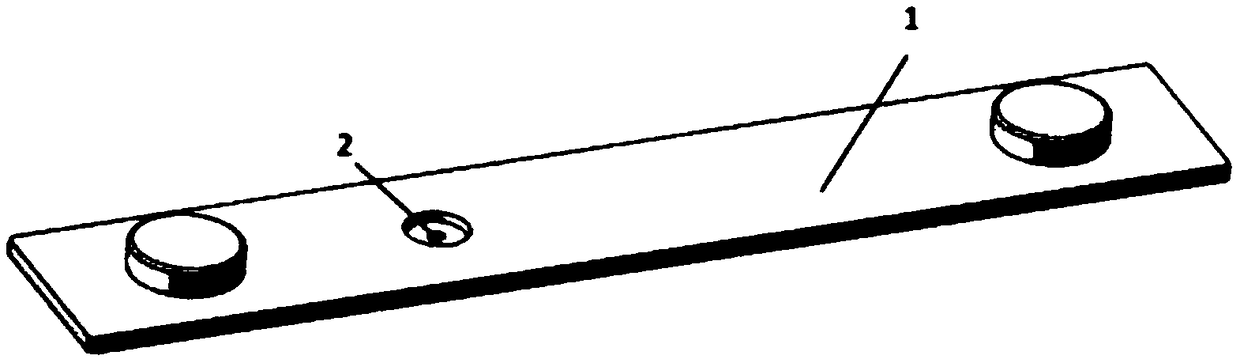

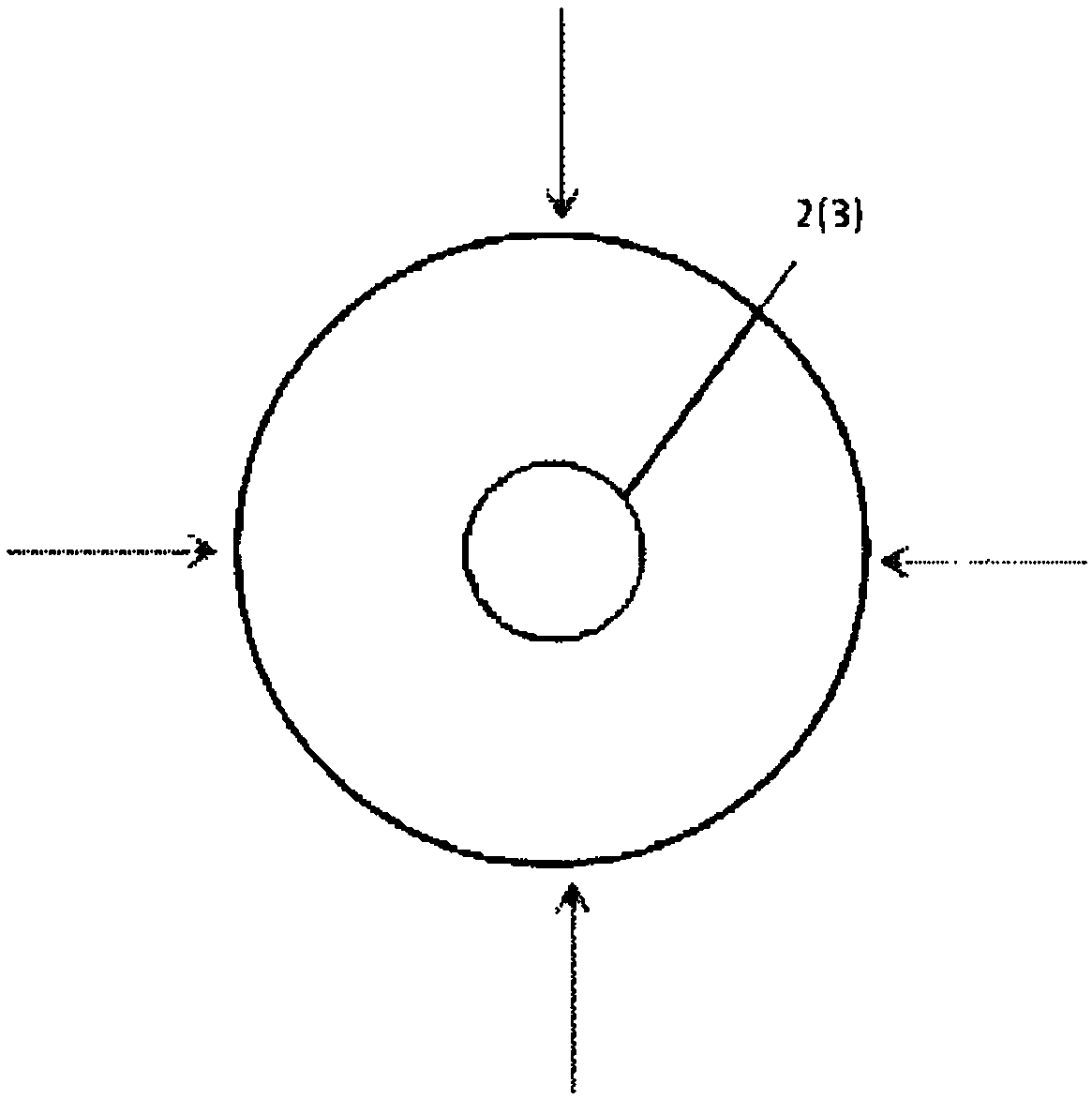

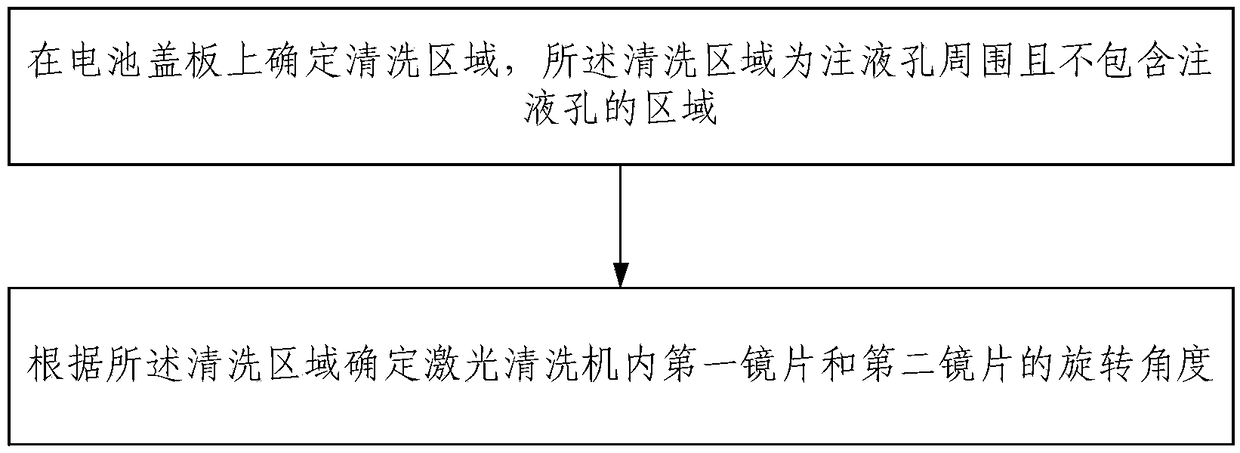

[0033] image 3 A preferred embodiment of the liquid injection hole 2 cleaning method on the battery of the present invention is shown, as image 3 As shown, the cleaning method includes: determining the cleaning area on the battery cover plate 1, the cleaning area is the area around the liquid injection hole 2 and not including the liquid injection hole 2; according to the cleaning area, the first lens 10 and the The angle of rotation of the second eyeglass 11; the first eyeglass 10 is inclined to the lower right, and the second eyeglass 11 is inclined to the upper right; the first eyeglass 10 is opposite to the laser head of the laser cleaning machine 7, and is positioned on the upper right of the second eyeglass 11 side; laser cleaning machine 7 also includes two motors; the motors are respectively connected with the first lens 10 and the second lens 11, and are respectively used to drive the first lens 10 and the second lens 11 to rotate.

[0034] Specifically, after the ...

Embodiment 2

[0042] Such as Figure 6 As shown, the present invention provides a cleaning device for the battery liquid injection hole 2, comprising: a laser cleaning machine 7; two motors, a rotatable first lens 10 and a second lens 11 are arranged in the laser cleaning machine 7; 10 is inclined to the lower right, and the second eyeglass 11 is inclined to the upper right; the first eyeglass 10 is opposite to the laser head of the laser cleaning machine 7, and is positioned at the upper right of the second eyeglass 11; the motor is connected to the first eyeglass 10 and the eyeglass respectively. They are connected and used to drive the first lens 10 and the second lens 11 to rotate respectively.

[0043] Specifically, the positional relationship between the first lens 10 and the second lens 11 in the laser cleaning machine 7 is as follows: Figure 4 As shown, and the first lens 10 and the second lens 11 are respectively connected to the motor, that is, one motor is connected to the firs...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com