Synthetic block of polycrystalline diamond composite sheet and method for synthesizing polycrystalline diamond composite sheet

A polycrystalline diamond and composite sheet technology, which is applied in the field of superhard material manufacturing, can solve the problems of inconsistent sintering degree between the center and edge of the diamond polycrystalline layer, obvious pressure and temperature gradients, and large performance differences, so as to reduce further loss , reduce heat transfer, good thermal insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

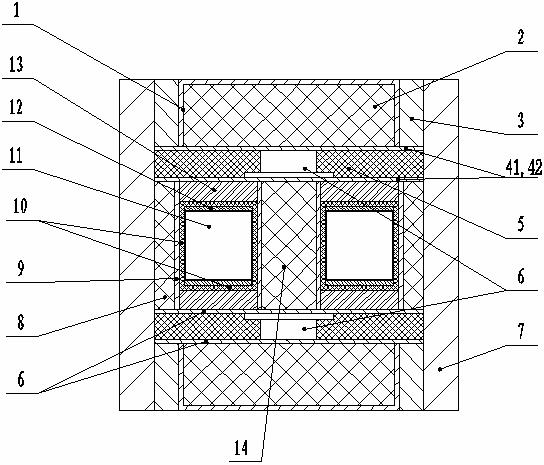

[0032] Simultaneously synthesize two polycrystalline diamond composite blocks at one time, such as figure 1 As shown, it includes a cylindrical synthetic cavity layer 8, a synthetic casing and an isolation layer 10. The synthetic cavity layer 8 is located in a hollow columnar synthetic casing, and the top and bottom of the synthetic cavity layer 8 are symmetrically provided with a conductive thermal insulation layer and Conductive pressure transmission layer, the middle part of the synthesis chamber layer 8 is provided with a synthesis stem 14, and a synthesis chamber is arranged around the synthesis stem 14, the synthesis chamber is located in the volume surrounded by the isolation layer 10, and the synthesis chamber is used to place the Crystalline diamond composite sheet stock 11, the top and bottom of the synthesis chamber are provided with insulating sheets 12, the top and bottom of the isolation layer 10 are provided with pressure transmission sheets 13, between the isola...

Embodiment 2

[0038] A kind of method utilizing synthetic block described in embodiment 1 to synthesize polycrystalline diamond compact, comprises the following steps:

[0039] 1) Place the pyrophyllite block 7 and the pyrophyllite ring 3 in a vacuum sintering furnace, and evacuate until the pressure in the furnace reaches 3×10 - 2 Below Pa, heat to 280°C and keep it warm for 36 hours; the insulating sheet 12 is baked at 720°C for 8 hours, and set aside;

[0040] 2) Carry out resistance classification for the resistance of the heating tube 9, and the resistance error between the heating tubes 9 of the same type and the same specification material is not more than 1%;

[0041] 3) Place the polycrystalline diamond compact blank 11 in a vacuum sintering furnace, and roughly evacuate until the pressure in the furnace reaches 7×10 -2 Below Pa, heat to 180°C for 1 hour, then continue vacuuming and heat to 700°C until the pressure inside the furnace is stable at 3×10 -3 Below Pa, then stop vacu...

Embodiment 3

[0051] A kind of method utilizing synthetic block described in embodiment 1 to synthesize polycrystalline diamond compact, comprises the following steps:

[0052] 1) Place the pyrophyllite block 7 and the pyrophyllite ring 3 in a vacuum sintering furnace, and evacuate until the pressure in the furnace reaches 3×10 - 2 Below Pa, heat to 260°C and keep it warm for 48 hours; the insulating sheet 12 is baked at 750°C for 6 hours, and set aside;

[0053] 2) Carry out resistance classification for the resistance of the heating tube 9, and the resistance error between the heating tubes 9 of the same type and the same specification material is not more than 1%;

[0054] 3) Place the polycrystalline diamond compact blank 11 in a vacuum sintering furnace, and roughly evacuate until the pressure in the furnace reaches 7×10 -2 Below Pa, heat to 150°C for 1 hour, then continue vacuuming and heat to 650°C until the pressure inside the furnace is stable at 3×10 -3 Below Pa, then stop vacu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| percent by volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com