A strong shear chemical reactor

A chemical reactor, strong shear technology, applied in chemical/physical/physical-chemical stationary reactors, graft polymer adhesives, adhesive types, etc., can solve the problem of limited impact force, difficult industrialization, The long time required for vibration and other problems can achieve the effects of stable pressure field, high extrusion efficiency and high grafting rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

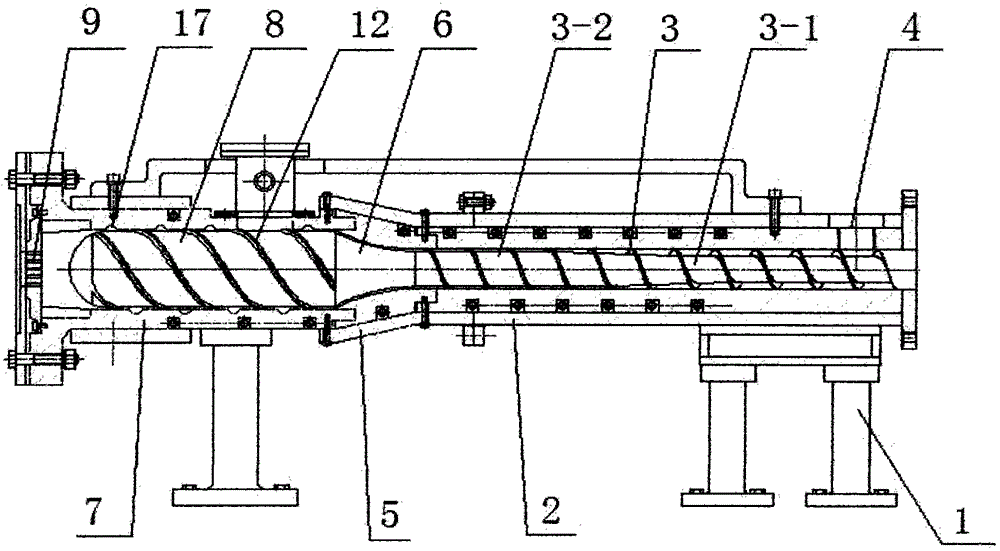

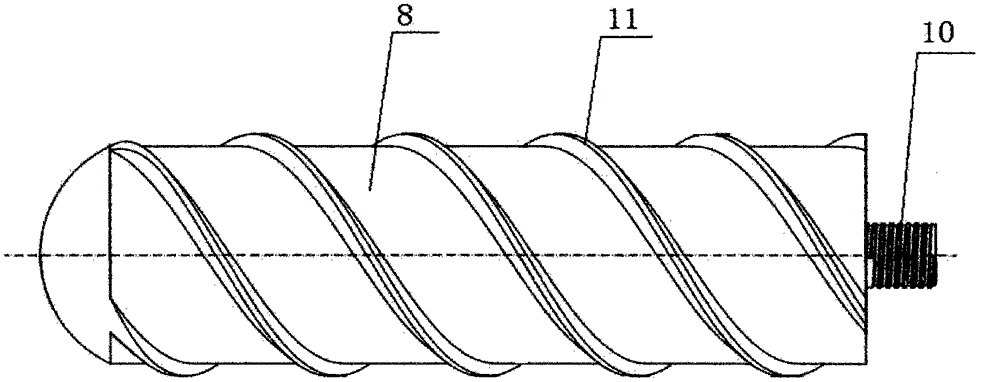

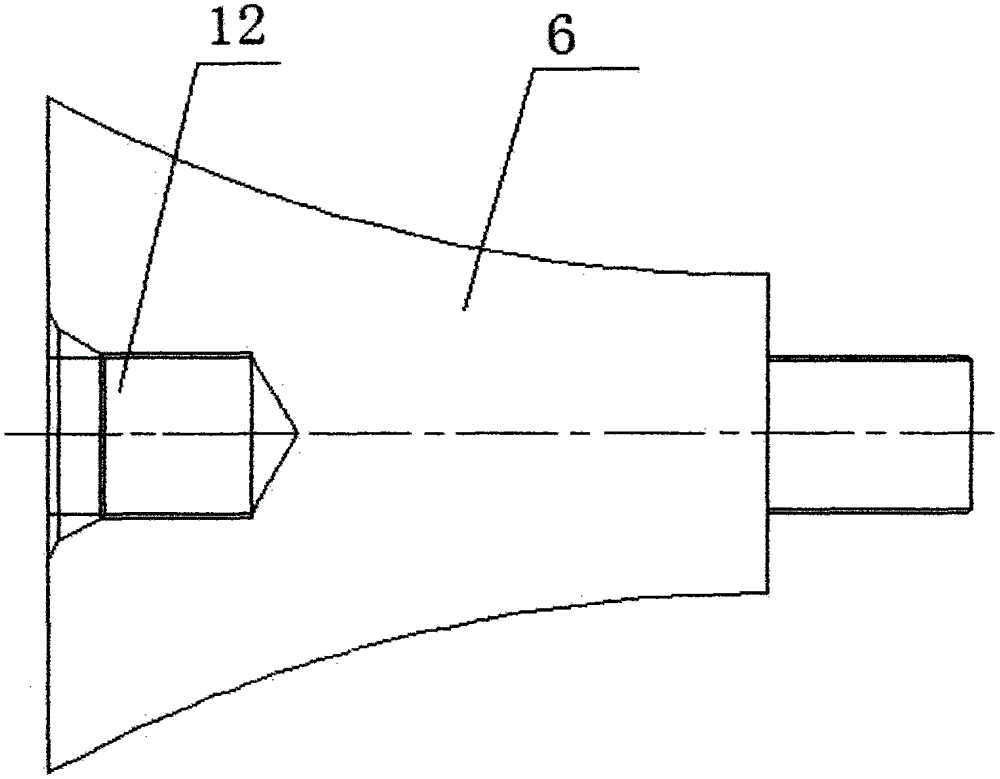

[0026] Such as figure 1 As shown, a kind of strong shear force chemical reactor of the present invention comprises frame 1, barrel 2, screw rod 3, and described barrel 2 is horizontally fixed on described frame 1, and described screw rod 3 can Rotatingly arranged in the barrel 2, the screw 3 is divided into a melting section screw 3-2 and a feeding section screw 3-1, and the barrel 2 where the feeding section screw 3-1 is located is provided with a feeding Port 4, the port of the barrel 2 where the screw 3-2 of the melting section is located is connected to the connecting barrel 5, and the inner cavity of the connecting barrel 5 is a circle that gradually increases from the connection end with the barrel 2 to the ot...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com