Steel truss girder unit lifting method used in lifting mode of single lifting point

A steel truss girder and mode technology, which is applied in the field of overall hoisting and installation of steel truss girder unit bridge positions of long-span steel structure cable-stayed bridges or suspension bridges, can solve the problems of increasing safety risks of construction operations, secondary damage to the surface of steel structures, Surface damage of steel structure panels and other problems, to achieve the effect of convenient and quick installation and dismantling, good construction effect and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] This embodiment provides a method for hoisting a steel truss girder unit in a single hoisting point hoisting mode, including the following steps:

[0033] Step 1, assembling the fabricated steel lifting lug device 1;

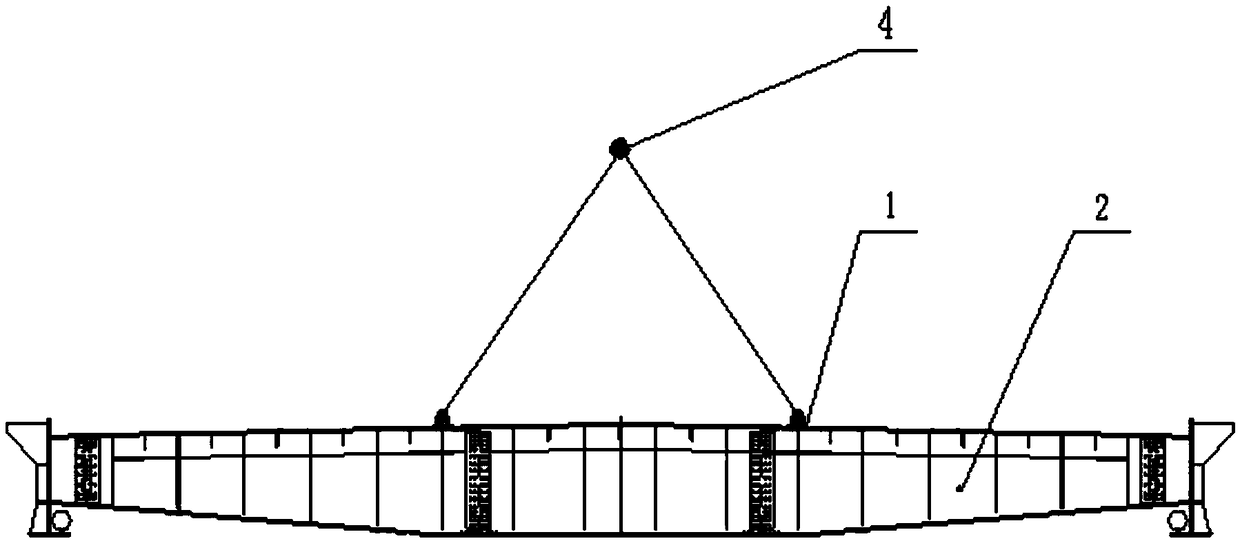

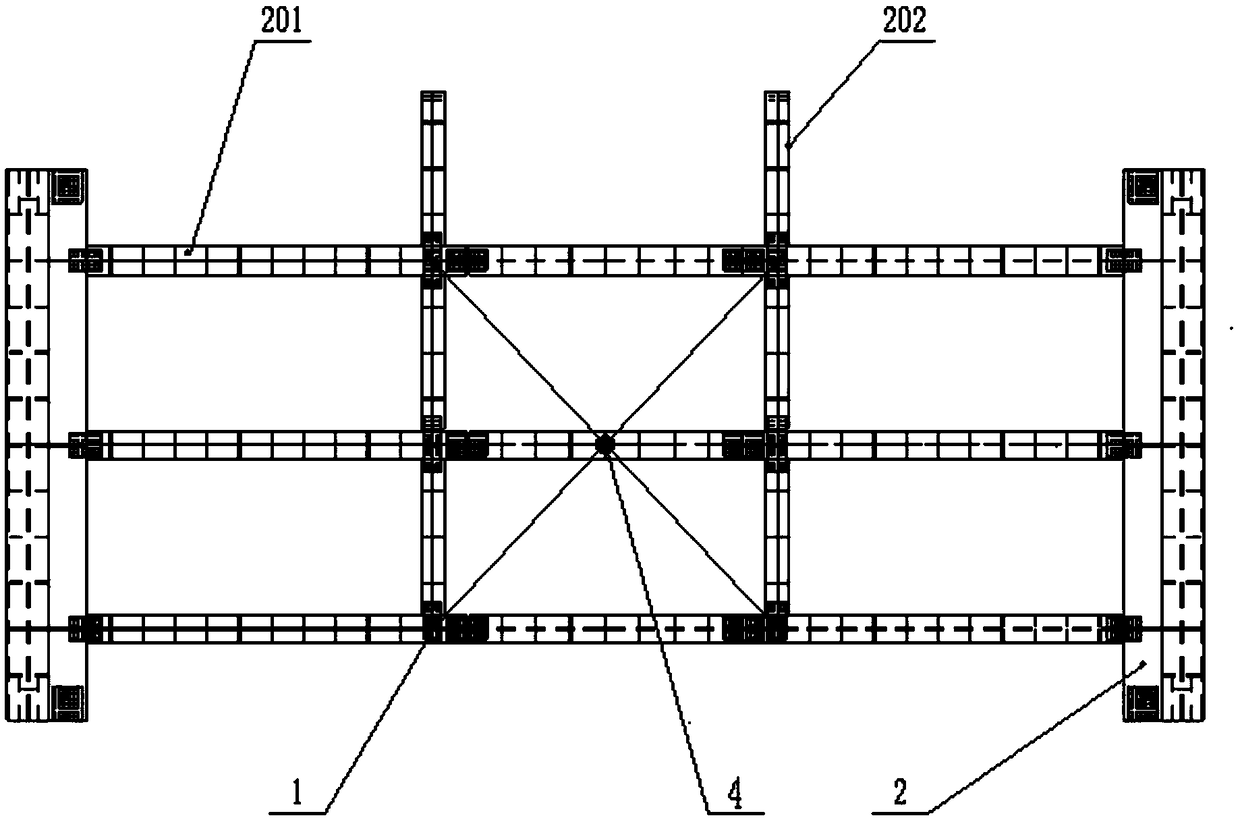

[0034] Step two, such as Image 6 As shown, select a plurality of positions for installing the assembled steel lifting lug device 1 on the beam or longitudinal beam of the steel truss beam unit 2, and fix the assembled steel lifting lug device 1 on the steel truss beam unit 2 through high-strength bolts 3 ;

[0035] Step 3: Transport the lifting equipment to the top of the steel truss girder unit 2. The lifting equipment is connected to the assembled steel lifting lug device 1 through multiple lifting wire ropes, slings or hanging plates. The number of lug devices 1 is the same, and the location of the assembled steel lug device 1 is the lifting connection lifting point. When lifting, all the lifting connection lifting points converge to the single lift...

Embodiment 2

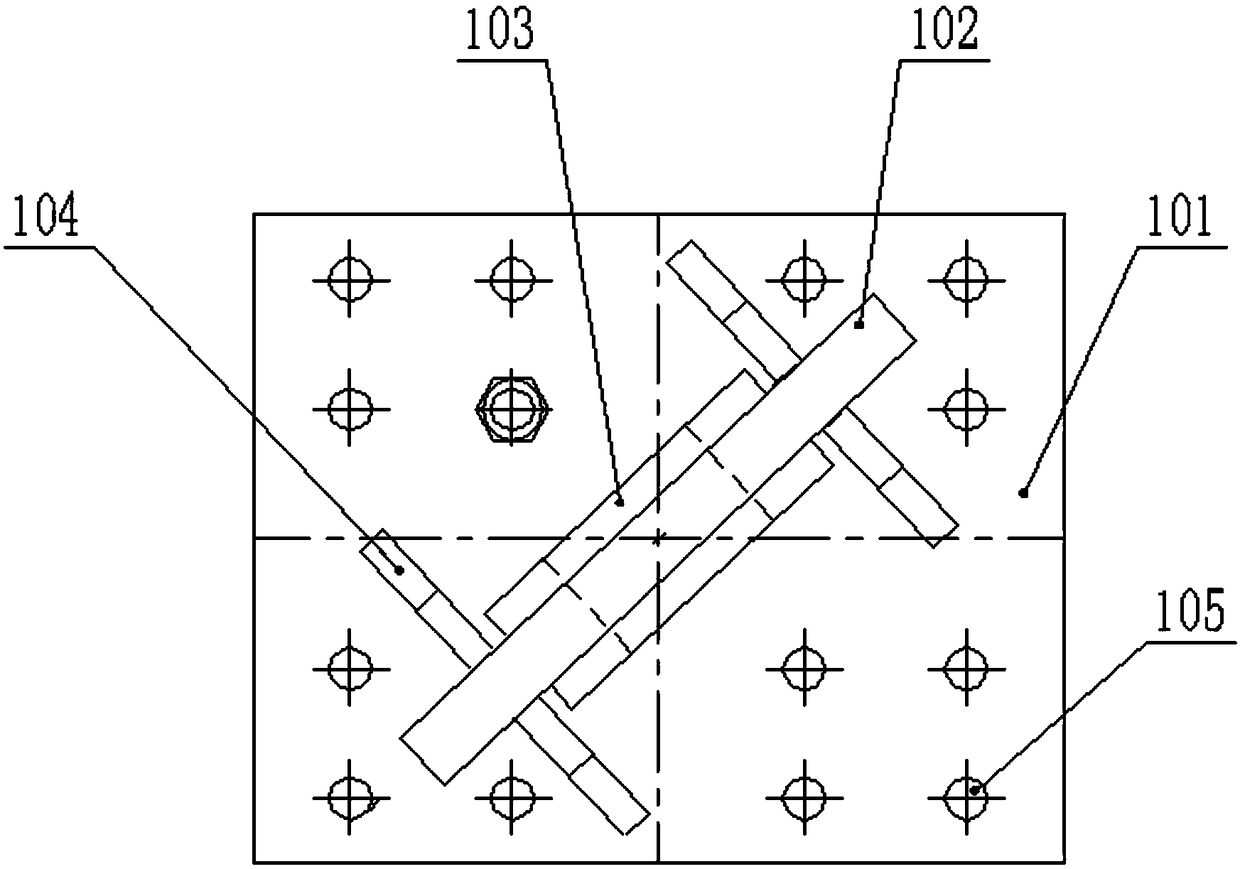

[0041] like image 3 , Figure 4 and Figure 5 As shown, on the basis of Example 1, the assembled steel lug device 1 is composed of a pressure-bearing connecting plate 101, an ear plate 102, a reinforcing plate 103 and a stiffening plate 104, and the pressure-bearing connecting plate 101 is rectangular As a steel plate member, the ear plate 102 is obliquely and vertically welded on the pressure-bearing connecting plate 101, and the center of the top of the ear plate 102 is provided with a hoisting hole. There are two reinforcing plates 103, and the two reinforcing plates 103 are respectively welded to the ear plate 102 and clamp the ear plate 102 in the middle, and the center of the reinforcing plate 103 is provided with a hoisting hole with the same specifications as the hoisting hole of the ear plate 102. There are several stiffening plates 104, and several stiffening plates The plates 104 are welded perpendicular to the ear plate 102 at the angle between the pressure-bear...

Embodiment 3

[0046] Preferably, the stiffening plate 104 is made of Q345 steel plate with a thickness of 12 mm. There are four stiffening plates 104 in total, and two of them form a group opposite to each other and are welded at the angle between the pressure-bearing connecting plate 101 and the lug plate 102 . Both the ear plate 102 and the reinforcing plate 103 are made of Q345 steel plate, the ear plate 102 is 30 mm thick, the reinforcing plate 103 is a circular steel plate with a diameter of φ220 mm and a thickness of 10 mm, and the ear plate 102 and the reinforcing plate 103 are hoisted through the same hole. The hole diameter is φ100mm. The size of the pressure-bearing connecting plate 101 is 500×400 mm, the thickness is 25 mm, and the material is a rectangular steel plate of Q345. There are several holes on the rectangular steel plate for connecting the pressure-bearing connecting plate 101 to the steel truss unit 2 Bolt holes 105.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com