Construction method of using tools to install rubber waterstop for bridge expansion joint

A construction method and technology of rubber belts, which are applied in the direction of erecting/assembling bridges, bridges, bridge parts, etc., can solve problems such as damage to waterstops, affecting the sealing quality of rubber waterstops and weathering steel, and water seepage at beam ends. Convex and convex wrinkles, smooth appearance, good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The tools used include flat shovels, curved shovels, front and back shovels, and lever shovels;

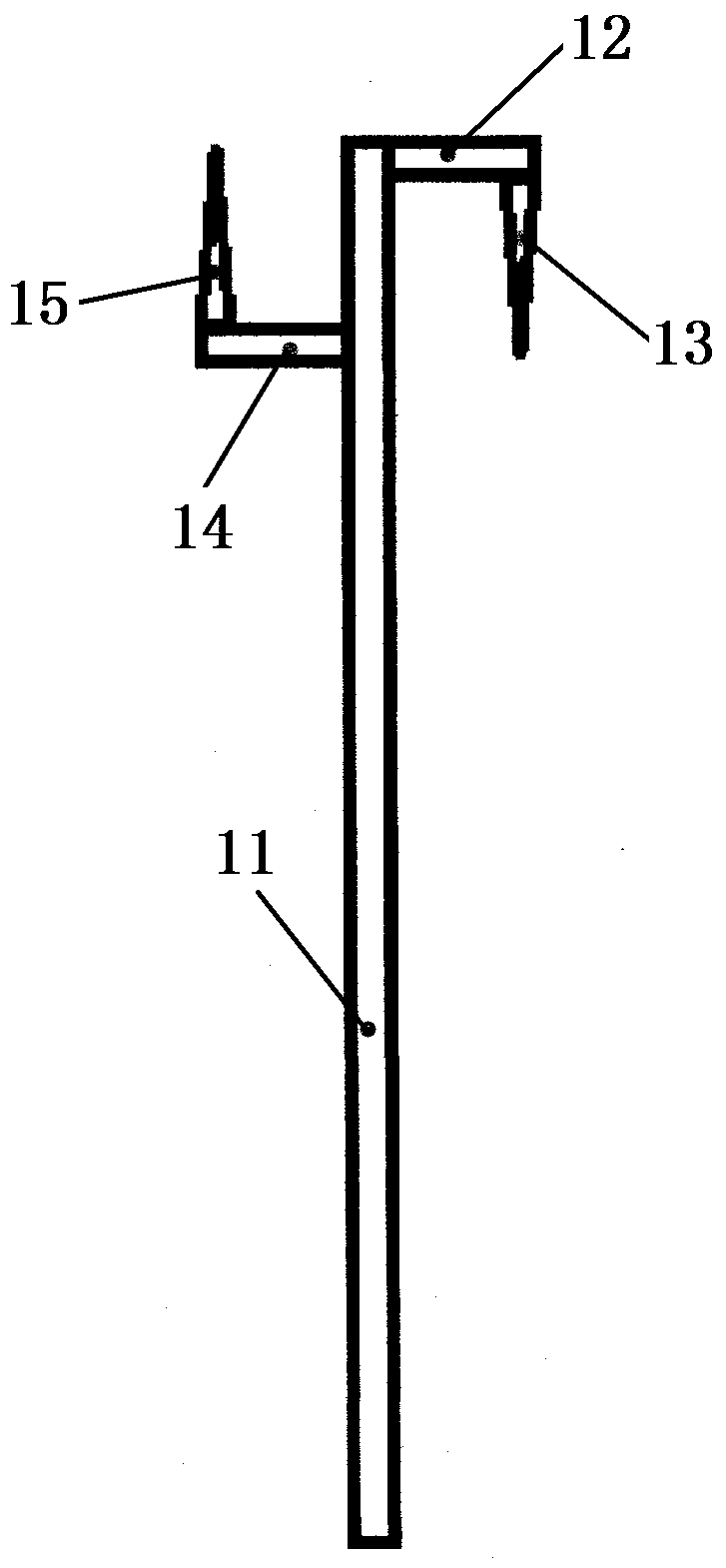

[0017] refer to figure 1 , the front and back hoe includes a handle 11, the front end of the handle is fixed with a right connecting plate 12, the front end of the right shovel head 13 is connected to the right connecting plate, the tip of the right shovel head faces backward, and the left connecting plate 14 is fixed behind the right connecting plate On the handle of the handle, the rear end of the left shovel head 15 is connected to the left connecting plate, and the tip of the left shovel head is forward;

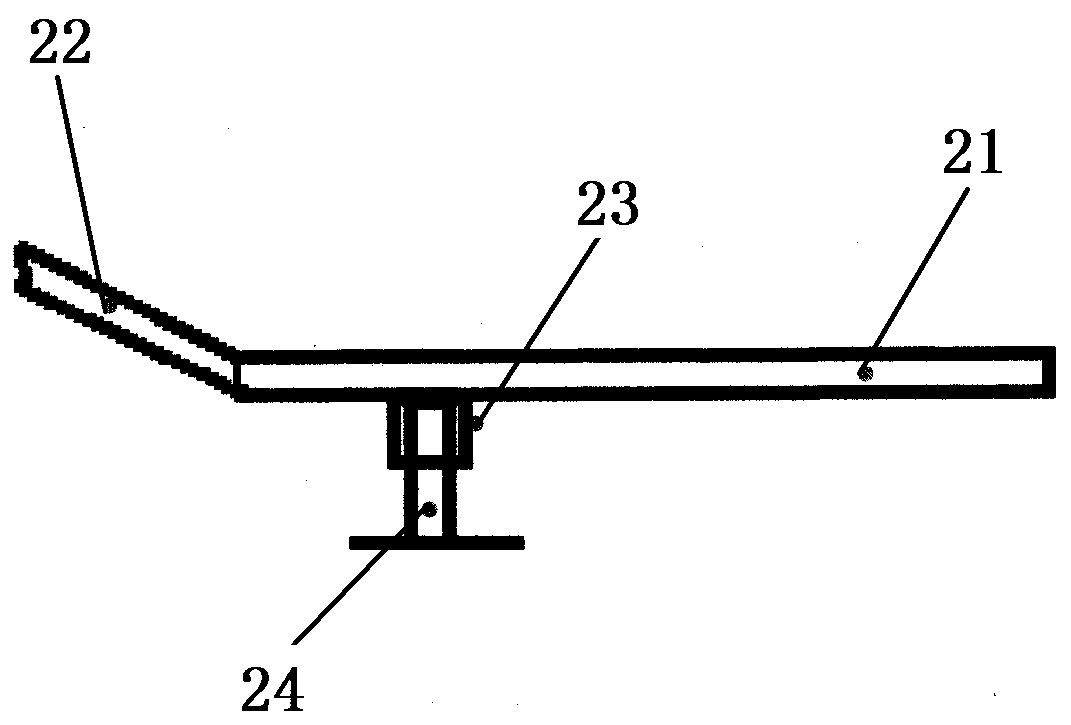

[0018] refer to figure 2 , the lever shovel includes a handle 21, the shovel head 22 is fixed on the front end of the handle, the front portion of the handle is fixed with a connecting sleeve 23, the inner wall of the connecting sleeve is threaded, and the adjusting bolt 24 is screwed in the connecting sleeve;

[0019] First, clean the expansion joints. During the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com