Cable-force uniformity monitor system and construction method for construction of parallel steel strand inclined stay cable

A technology of parallel steel strand and monitoring system, applied in tension measurement, bridge parts, erection/assembly of bridges, etc., can solve problems such as beam deformation and uneven force, achieve high work efficiency, low labor cost input, and simple operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

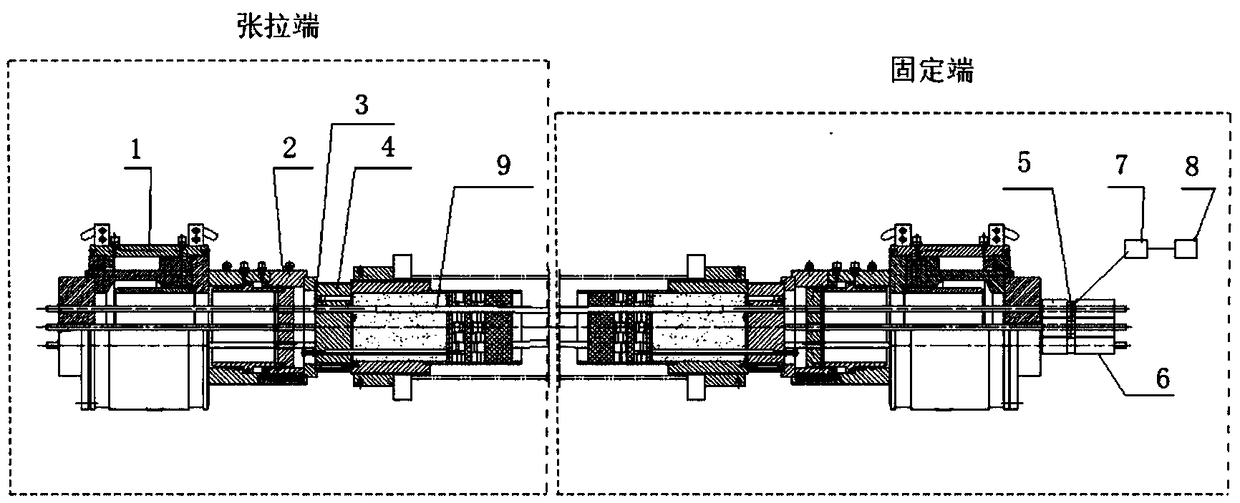

Embodiment approach 1

[0016] A cable force uniformity monitoring system for parallel steel strand cable-stayed cables during construction, characterized in that it includes a tension end and a fixed end of steel strand cable-stayed cables, and the steel strand tension end includes a working anchor Plate 3, working clip 4, top pressure jack 2, tension jack 1, working anchor plate 3 is worn on steel strand stay cable 9, working clip 4 is located on working anchor plate 3, and the top pressure jack 2 Installed on the rear end of the working anchor plate 3, it is used to tighten the working clip 4 after the tensioning is completed; pull; the pressure sensor 5 is installed on the steel strand stay cable 9 at the fixed end of the steel strand stay cable, and each steel strand stay cable 9 is equipped with a pressure sensor 5; A grip-wrapped anchorage tied on the steel strand stay cable 9 is used to form pressure on the pressure sensor 5 when the steel strand stay cable 9 is stretched; the data acquisitio...

Embodiment approach 2

[0018] The process of using this system to monitor the construction of steel strand stay cables is as follows: step 1, installation of the cable force uniformity monitoring system for parallel steel strand stay cables; step 2, determining the steel strand stay cable according to the tension force 0-100% F graded tensioning process of 9, start the tensioning jack 1 top pair of parallel steel strand cables 9 overall graded tensioning, squeeze the sleeve and squeeze the pressure sensor; step 3, after the tensioning force of each stage is loaded , within the pressure holding time, the upper computer 8 controls the data acquisition module 7 to collect the data of the pressure sensor 5, and uses the cable force value of each steel strand stay cable 9 collected as the tension control force value, and records The cable force value of each steel strand stay cable 9; step 4, the upper computer 8 reads the cable force value monitored by the pressure sensor 5 through the data acquisition m...

Embodiment approach 3

[0020] On the basis of Embodiment 2, the graded tensioning in step 2 can be divided into five grades of tensioning: 20% F, 40% F, 60% F, 80% F, and 100% F.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com