Decorative sheet foamed by straw and manufacturing technology of decorative sheet

A manufacturing process and decorative panel technology, applied in covering/lining, layered products, construction, etc., can solve the problems of surface panel deformation, affecting appearance, insufficient internal strength, etc., to achieve improved impact resistance, increased weight, and increased strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

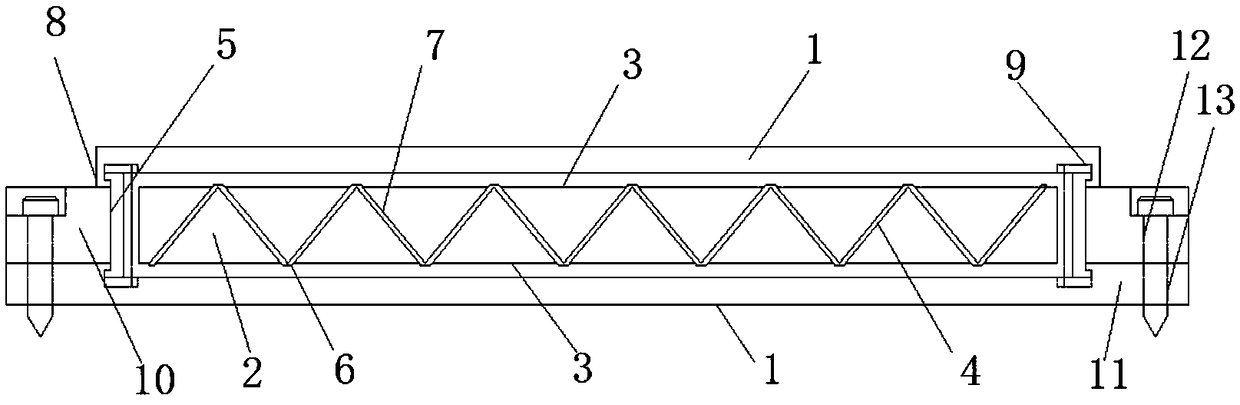

[0036] Such as Figure 1-Figure 5 As shown, the present invention provides a straw foamed decorative board, which includes two surface boards 1 arranged on the upper and lower sides and a foamed sandwich layer 2 located between the surface boards 1. The foamed sandwich layer 2 Straw segments with a length of 2-6mm are uniformly mixed. A reinforcing frame is also provided between the surface plates 1, and the foamed sandwich layer 2 fills the gap portion of the reinforcing frame. The reinforcing frame includes two layers of grid plates 3 respectively laid on the inner sides of the two layers of the surface panels 1 and a supporting plate connected to the grid plates 3. The inner side of the grid plate 3 is provided with a number of mounting grooves 16 with a trapezoidal cross section. The supporting plate is a corrugated plate 4 with triangular grooves. The top of the corrugated plate 4 is ground and flat with the mounting groove 16 With the matching trapezoidal structure, the...

Embodiment 2

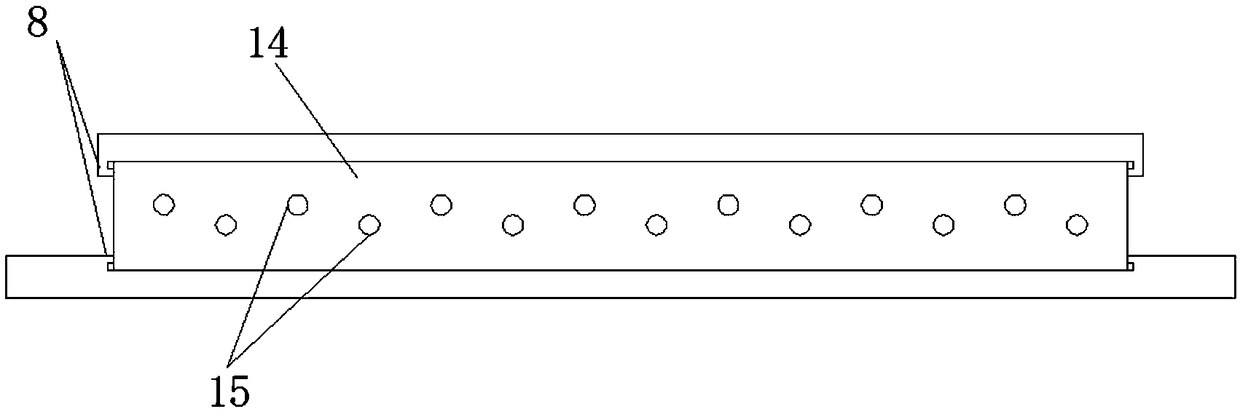

[0056] The basic structure and manufacturing process of the decorative board in this embodiment are the same as those in the first embodiment. The difference lies in that: before the surface board 1 is manufactured, a model including the surface board 1, the side sealing board 14 and the side connecting board 5 is scaled down and manufactured. The surface plate 1 is a flat plate, and the side part of the corrugated plate 4 adjacent to the side connecting plate 5 is fixed in the model, and the side connecting plate 5 is slidably installed in the model. Mark the initial position of the side connecting plate 5, and inject the mixed foaming material into the cavity between the side part of the corrugated board 4 and the side connecting plate 5 according to the ratio, and conduct a foaming test. After the foaming is completed, measure the foamed side The moving distance l of the connecting plate 5 is calculated in proportion to the moving distance L of the side connecting plate 5 in ...

Embodiment 3

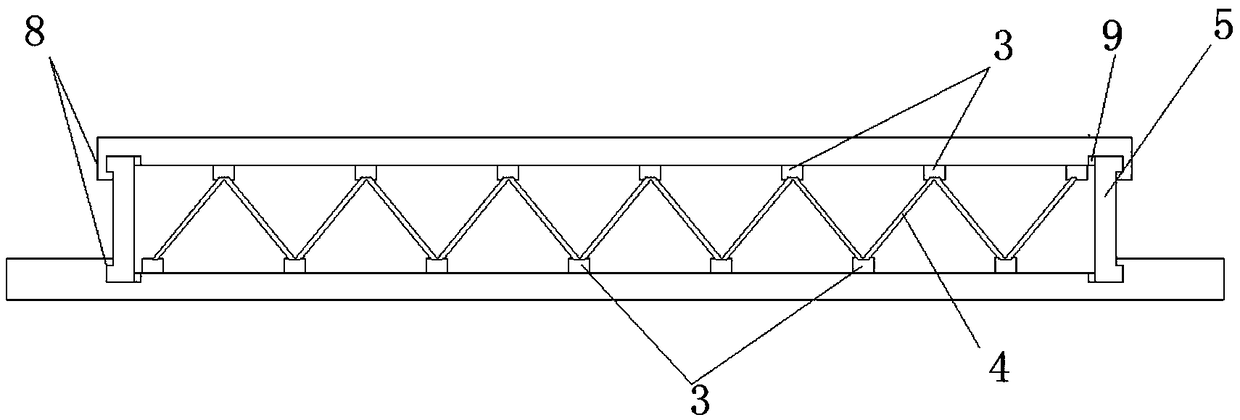

[0058] The basic structure and manufacturing process of the decorative board in this embodiment are the same as those in Embodiment 1, and the difference lies in the structure of the grid board 3. The grid on the grid plate 3 is in a rhombus shape, the grid ribs 17 forming the grid intersect with the ribs 6 of the corrugated plate 4 obliquely, and the installation groove 16 is provided at the intersection between the grids or the grid plate 3 on the side. The structural grid plate 3 can decompose the longitudinal force under the action of the longitudinal force of the corrugated plate 4, and the structural strength is higher than that in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com