Lateral telescopic casing-following drilling tool

A telescoping technology for heel pipe drilling tools, which is applied in the fields of geotechnical drilling and water well construction. It can solve problems such as the adverse effects of pipe boots and casings, affecting the depth of heel pipes, and affecting the quality of drilling, so as to improve drilling performance. Efficiency, improve the efficiency and depth of the follow-up pipe, and the effect of light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In order to make the purpose, technical solutions and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with specific embodiments and with reference to the accompanying drawings. The "first" and "second" used in the present invention are not Indicates any order, quantity, or importance and is used only to distinguish different components.

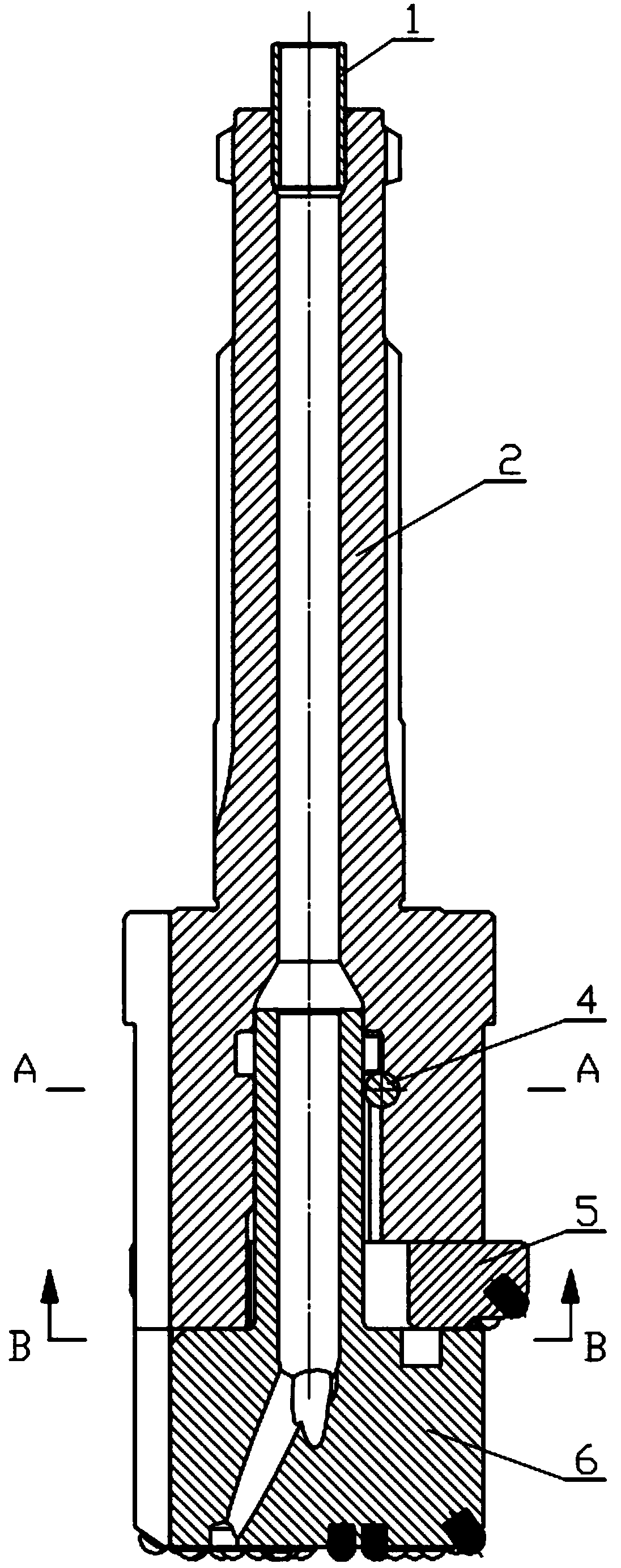

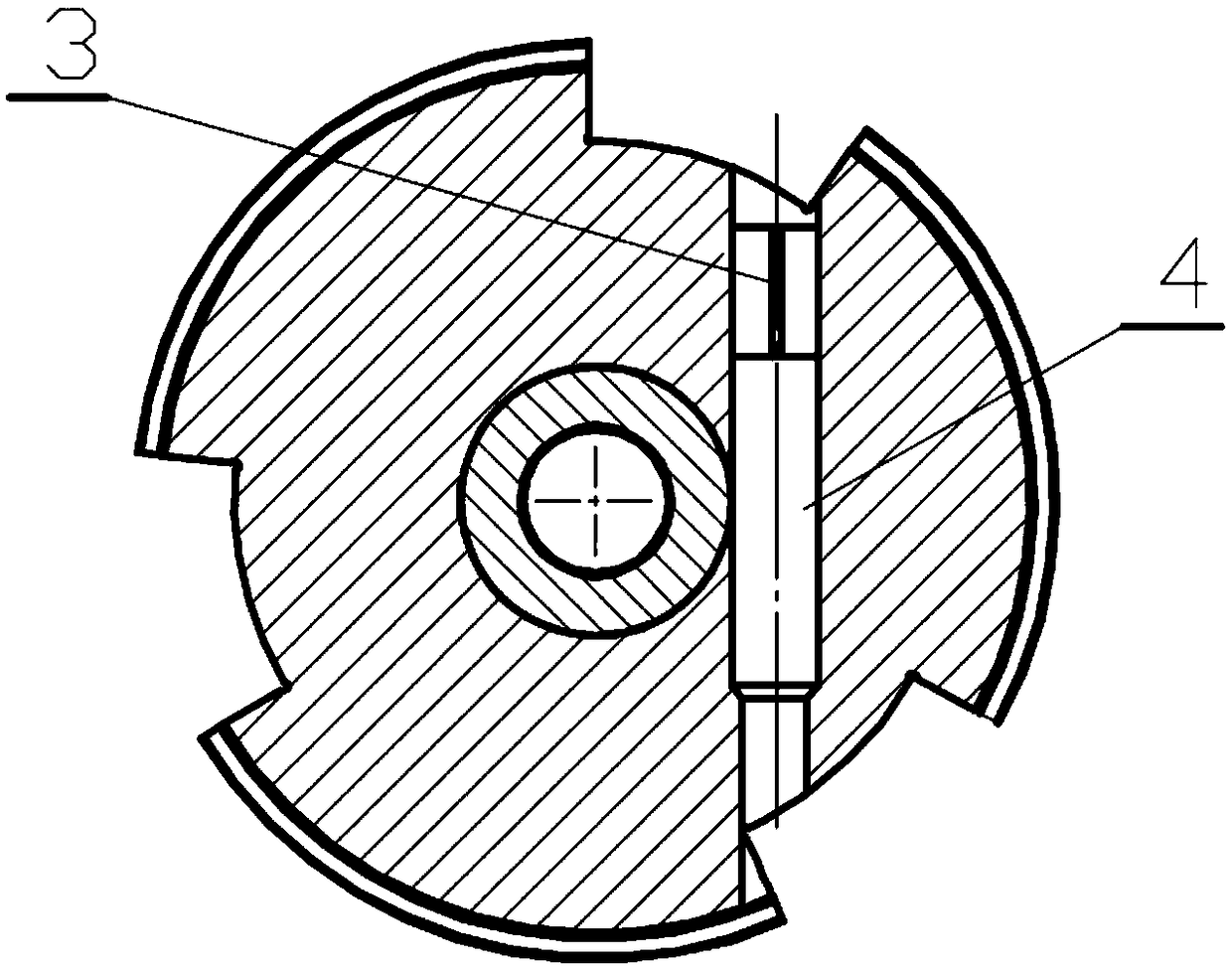

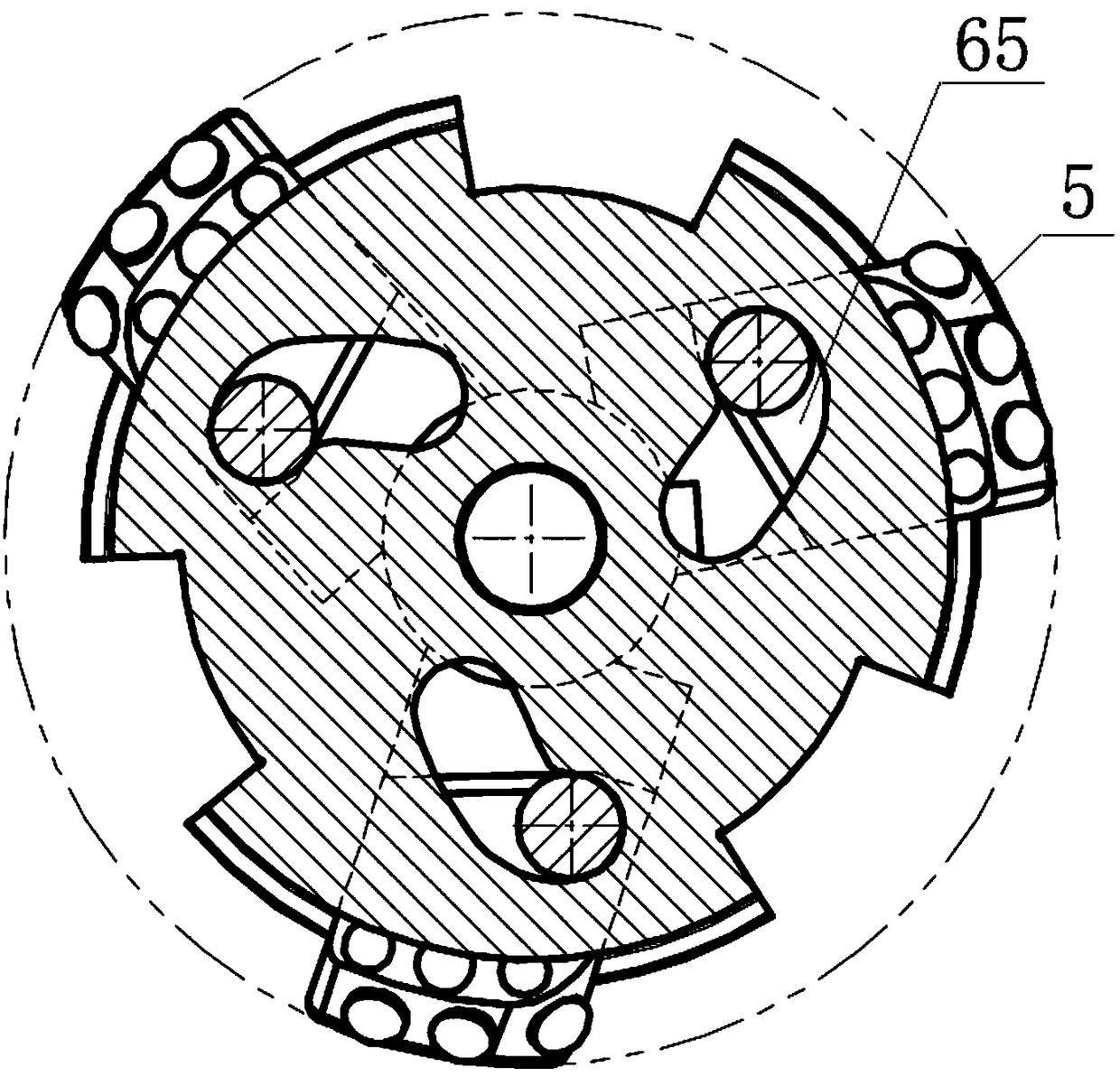

[0040] Such as Figure 1 to Figure 8 As shown, the laterally telescopic follow-up drilling tool includes a nylon sleeve 1, a drill body 2, an elastic pin 3, a suspension cross pin 4, a reaming drill 5 and a center drill 6.

[0041] Described center bit 6 is positioned at the below of bit body 2, and center bit 6 is divided into bit head and is used to connect the location central tube 63 of bit body, and drill head is cylindrical, and the diameter of location center tube 63 is less than the diameter of drill head. Diameter, the positioning central tube 63 is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com