Control method for reducing engine oil dilution level of in-cylinder direct injection gasoline engine

A technology of direct injection and dilution level in the cylinder, which is applied in the direction of machine/engine, engine lubrication, mechanical equipment, etc., can solve the problems of reduced dynamic optimization potential of spray motion and high oil dilution level, so as to reduce the amount of oil dilution and reduce piston Air leakage, reducing the effect of oil dilution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

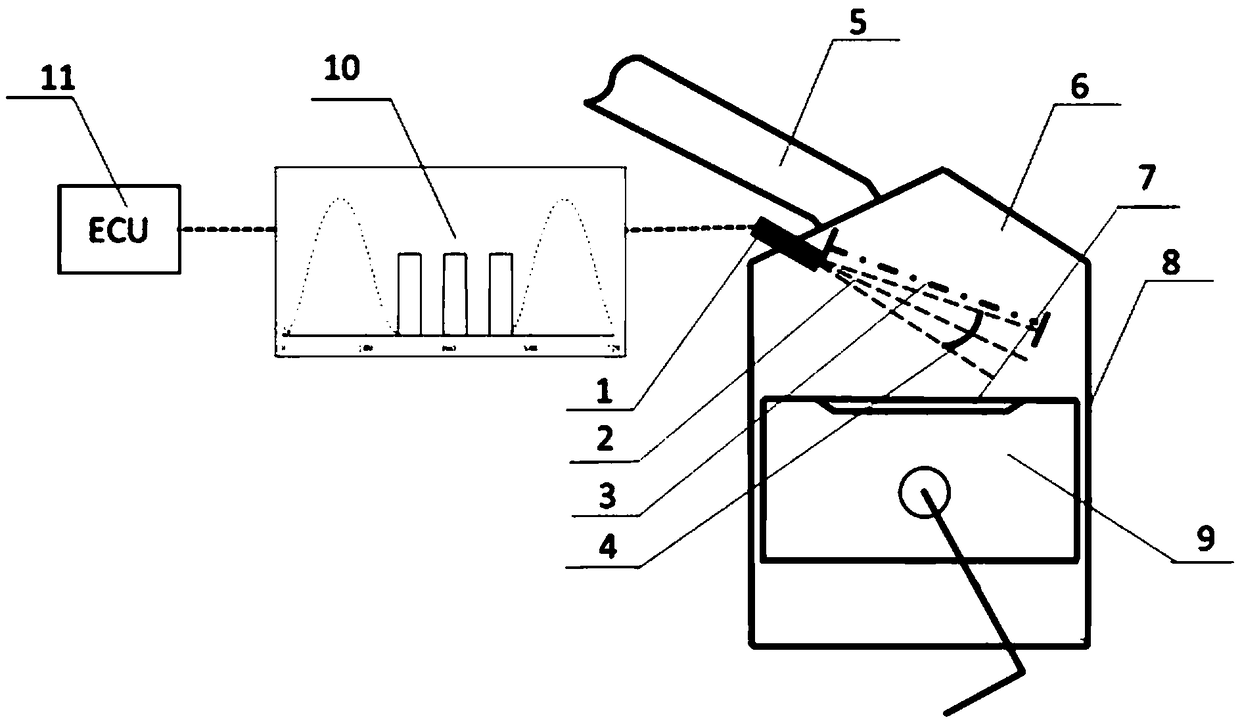

[0036] The present invention will be further described below in conjunction with accompanying drawing.

[0037] A control method for reducing the oil dilution level of an in-cylinder direct-injection gasoline engine, on the basis of liquid gasoline source control, gaseous gasoline source control, gaseous gasoline enhanced precipitation control and gaseous gasoline enhanced recovery control are added; the control method includes the following steps :

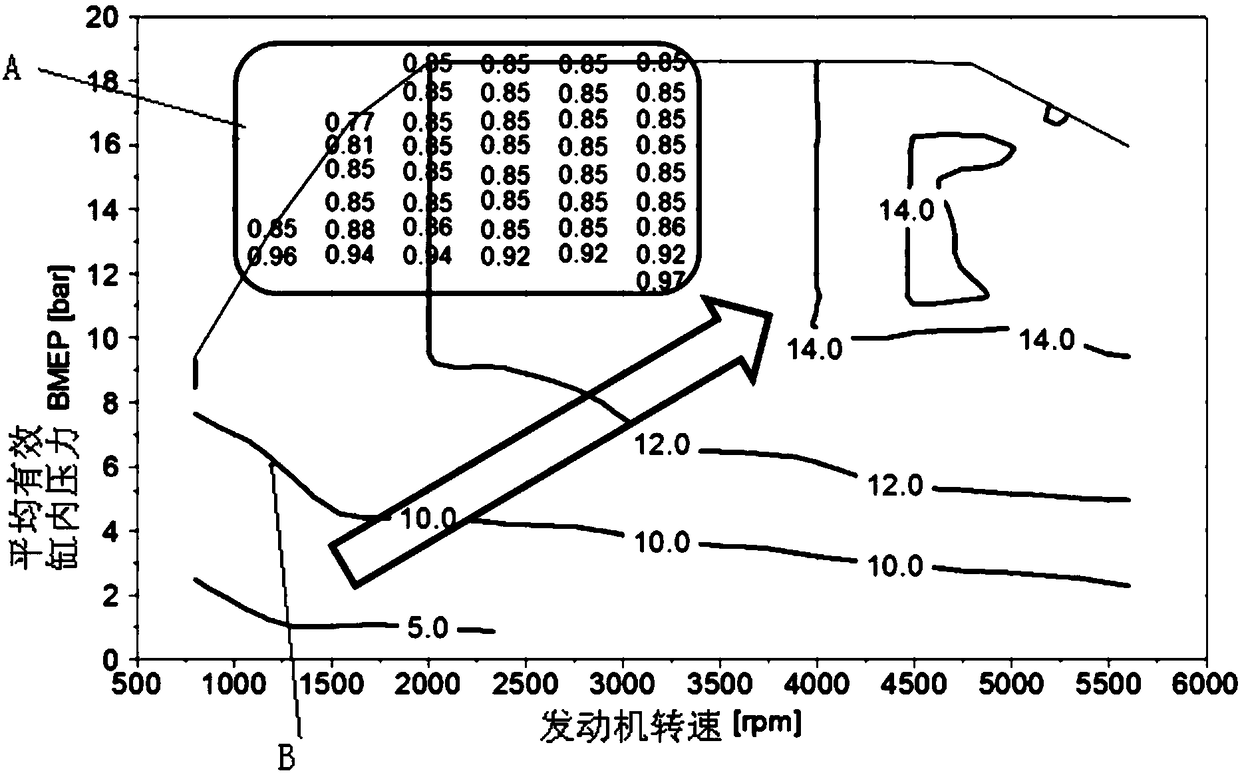

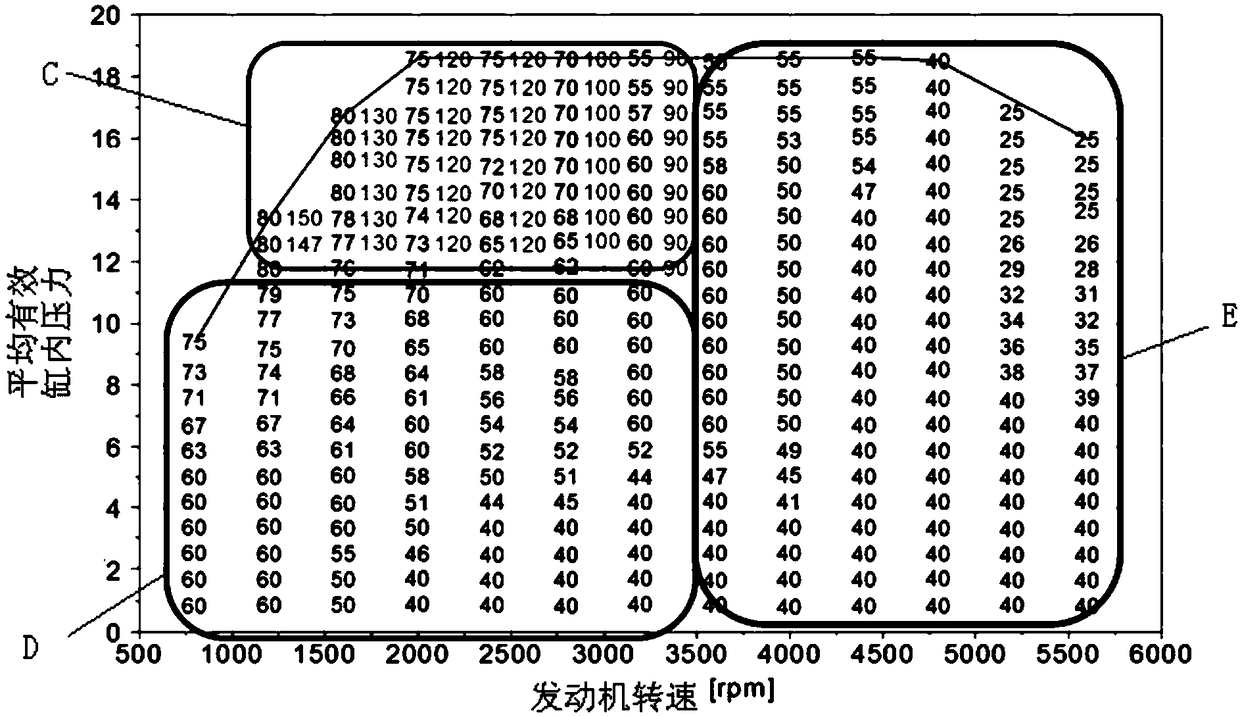

[0038] (1) Liquid gasoline source control: optimize the structure of the combustion system and the fuel injection control strategy of the in-cylinder direct injection gasoline engine.

[0039] When the engine is in the intake and compression strokes, combined with the optimized mechanical structure of the combustion system, through the optimized fuel injection control strategy, the amount of liquid gasoline injected into the engine cylinder and hit the cylinder wall is controlled to reduce the oil dilution level the goal of.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com