Engine oil dilution improvement device

An oil and fuel technology, applied in mechanical equipment, engine components, machines/engines, etc., can solve the problems of low cost performance, high cost, low absolute fuel quantity, etc., to optimize oil dilution, reduce the degree of oil dilution, and eliminate mixing Possible Effects of Oil Pans

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

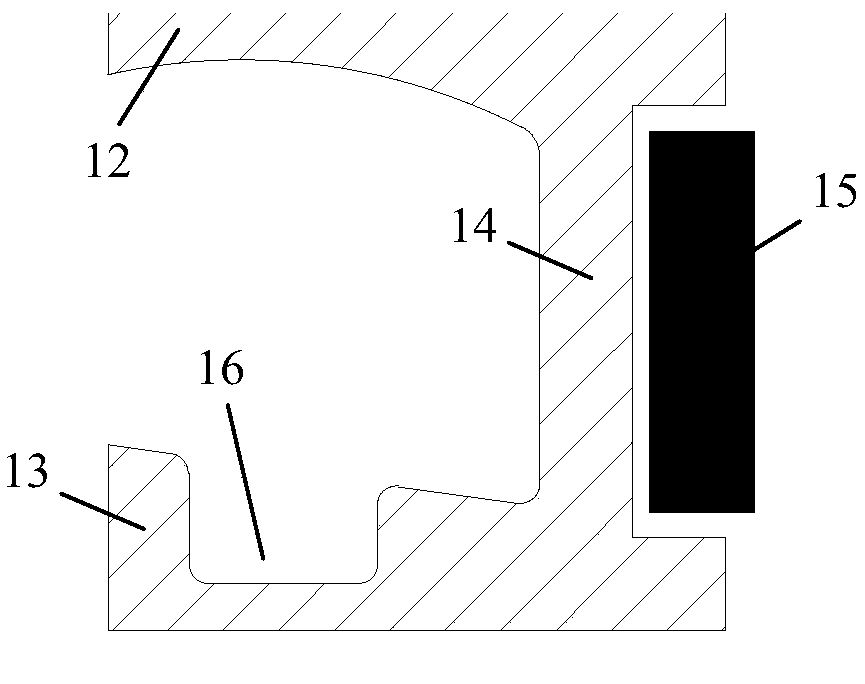

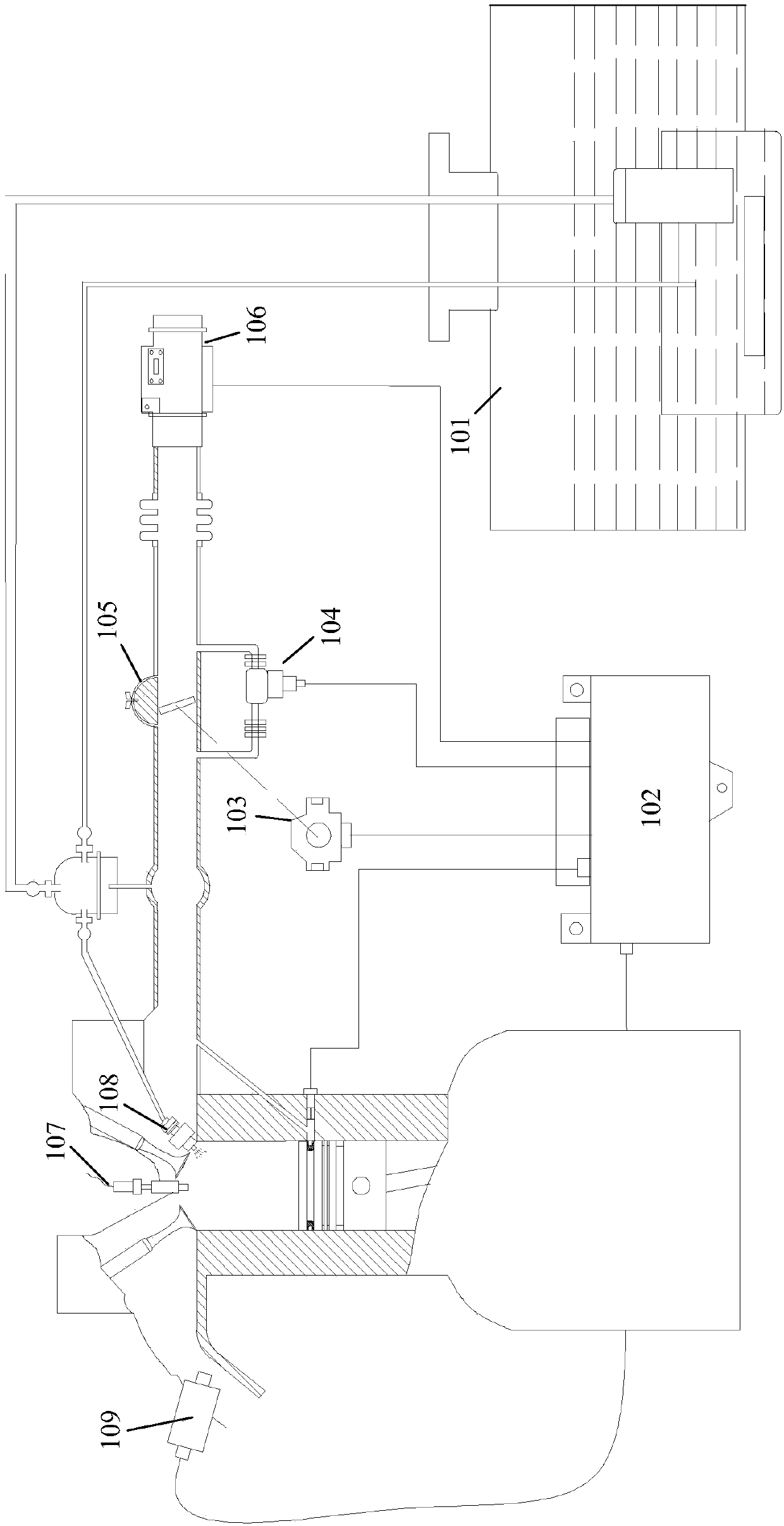

[0066] figure 1 is a schematic diagram of the overall structure of the engine control system equipped with the first embodiment of the device for improving engine oil dilution of the present invention. figure 2 is a schematic diagram of an engine cylinder equipped with a first embodiment of the device for improving oil dilution of the present invention. It can be seen that, in addition to the device for improving engine oil dilution of the present invention, the engine control system also includes a fuel pump 101, an electronic control unit 102, a throttle valve position switch 103, an idle speed actuator 104, a pressure regulator 105, an air flow rate Meter 106, spark plug 107, nozzle 108, oxygen sensor 109 and other components, the engine cylinder also includes spark plug 107 and nozzle 108 and other components. Since the structures of these components and their connections are known to those skilled in the art and are not directly related to the inventive concept of the p...

no. 2 example

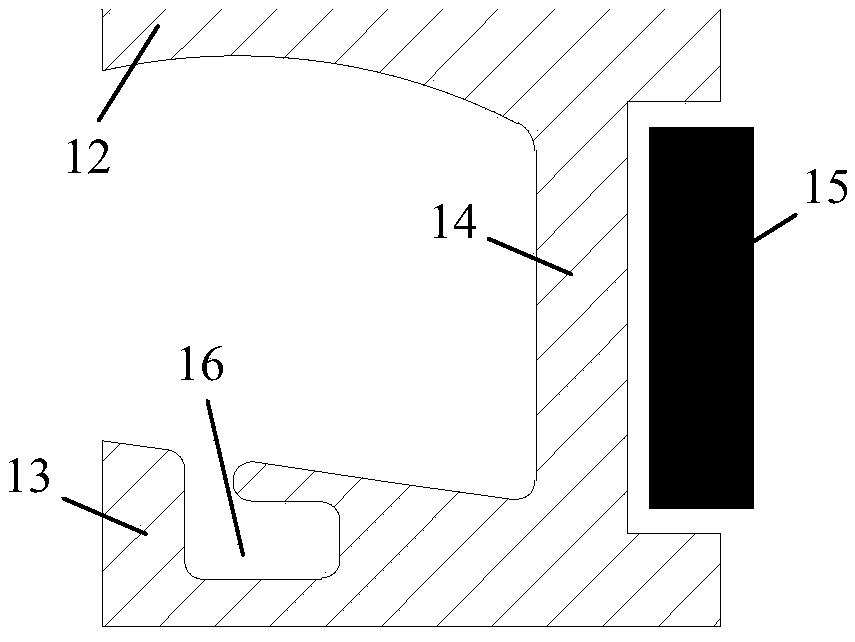

[0074] Figure 4 is a schematic diagram of the general structure of the engine control system equipped with the second embodiment of the device for improving engine oil dilution of the present invention. Figure 5 is a schematic diagram of an engine cylinder equipped with a second embodiment of the device for improving oil dilution of the present invention. Figure 6 A second embodiment of the device for improving oil dilution according to the invention is shown. The above drawings and Figures 1 to 3 The content shown is basically similar.

[0075] In the second embodiment of the present invention, the device for improving engine oil dilution includes an oil collector ring 10 for scraping Coanda fuel and an electronically controlled valve 11 for sucking fuel oil from the oil collector ring 10 . A total of five ring grooves are designed on the piston wall of this embodiment. Figure 6 In the middle direction from top to bottom, there are heat insulation groove 1, oil colle...

no. 3 example

[0078] Figure 7 is a schematic diagram of the overall structure of an engine control system equipped with a third embodiment of the device for improving engine oil dilution of the present invention. Figure 8 is a schematic diagram of an engine cylinder equipped with a third embodiment of the device for improving oil dilution of the present invention. Figure 9 A third embodiment of the device for improving oil dilution according to the invention is shown. The above drawings and Figures 1 to 3 The content shown is basically similar.

[0079] In the third embodiment of the present invention, the device for improving oil dilution includes an oil collector ring 10 for scraping Coanda fuel and an electronically controlled valve 11 for sucking fuel oil from the oil collector ring 10 . A total of four ring grooves are designed on the piston wall of this embodiment. Figure 9 Along the middle direction from top to bottom are the first gas ring groove 2, the second gas ring groo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com