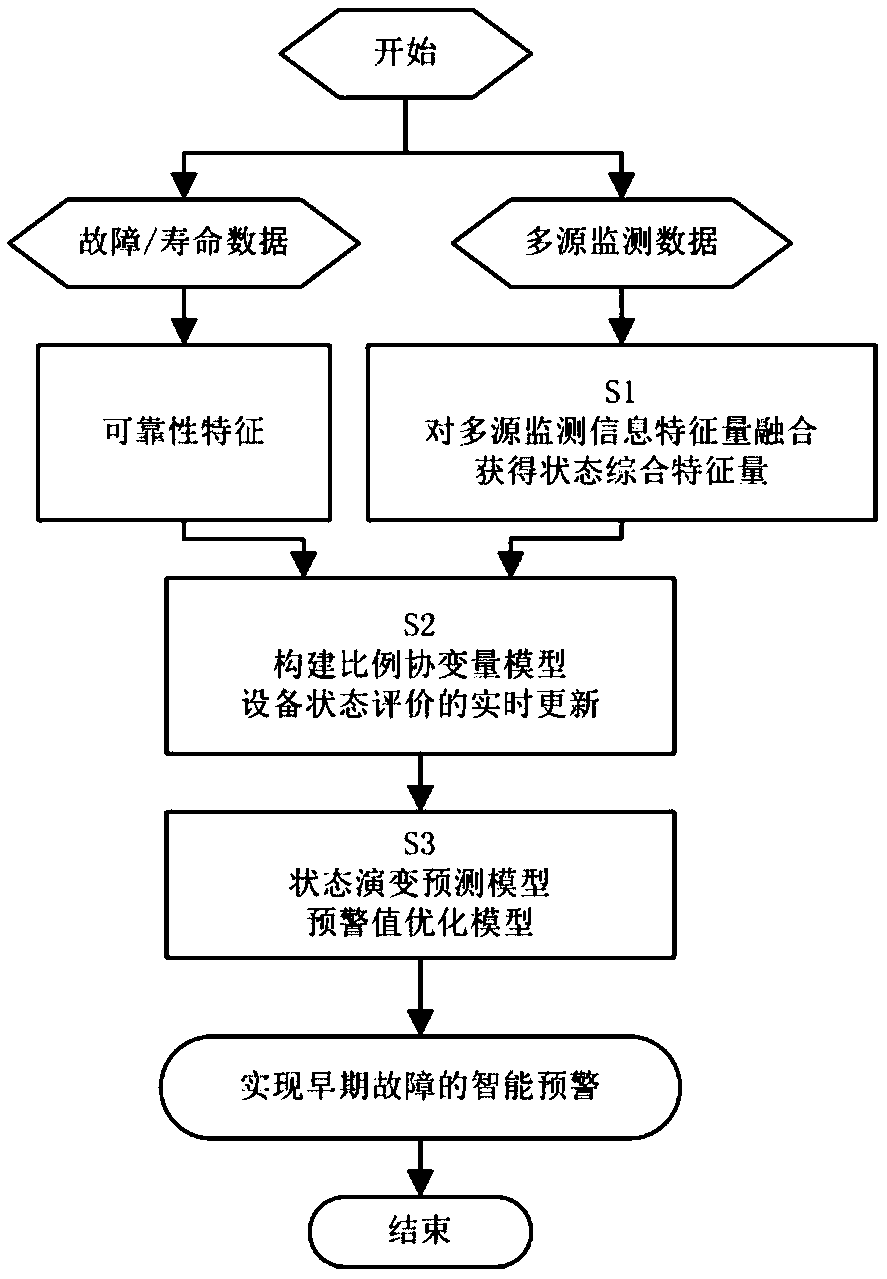

An early fault prediction method for hydraulic equipment based on the fusion of multi-source condition monitoring information and reliability features

A technology for monitoring information and early failures, applied in character and pattern recognition, instruments, computer components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

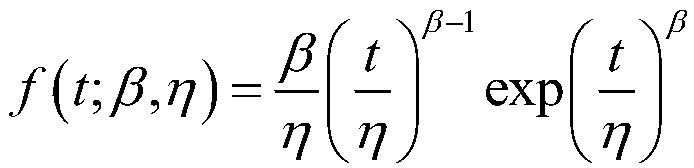

Method used

Image

Examples

Embodiment Construction

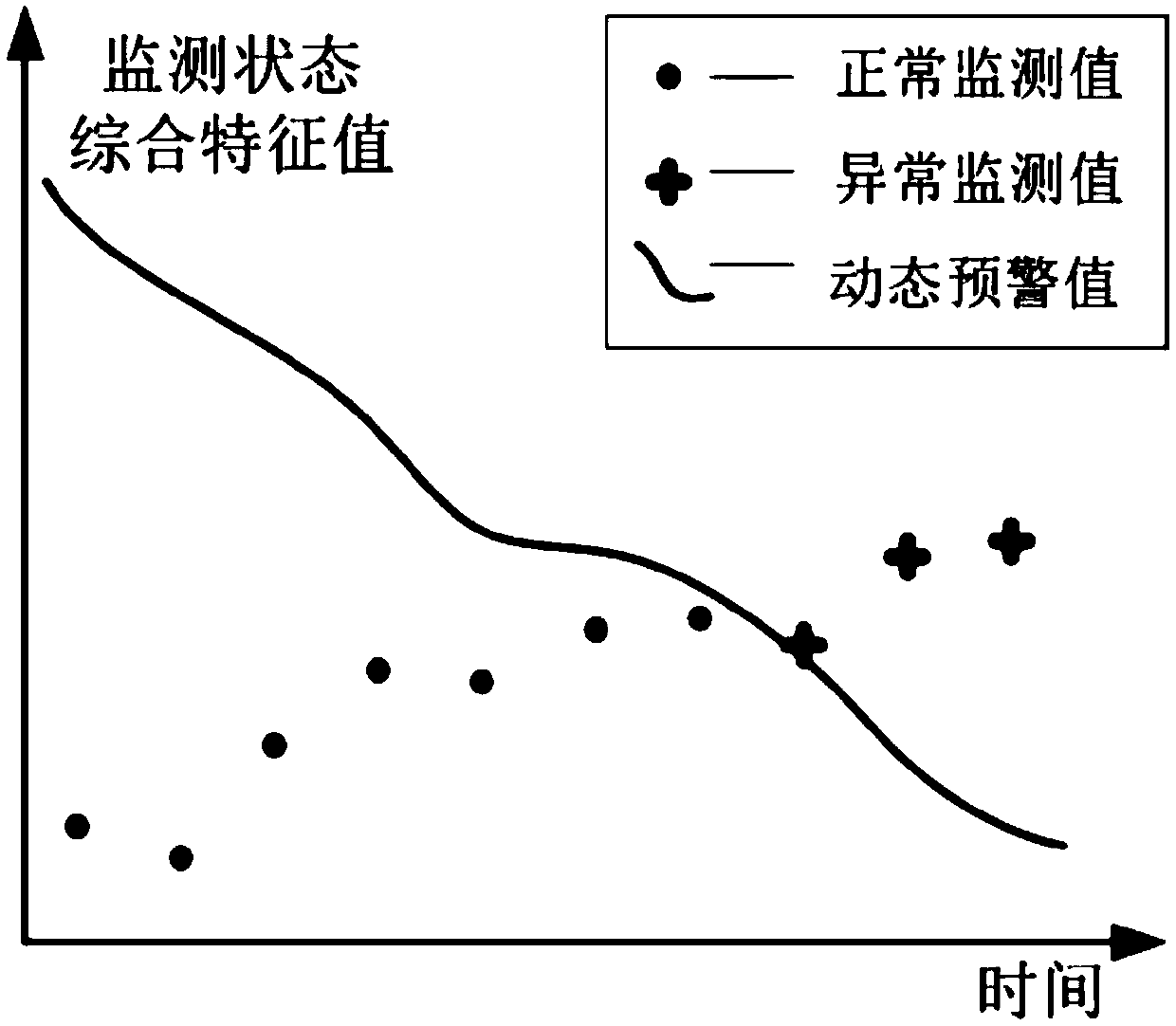

[0060] 1. To identify the signal feature quantity, the method is as follows:

[0061] Take the state space of the feature quantity as the vertical direction, and take the time scale as the horizontal direction to quantitatively characterize the signal feature quantity;

[0062] 2. Based on the fusion of multi-source monitoring information, the comprehensive feature value identification of the state is carried out, the method is as follows:

[0063] The self-organizing map neural network is used to fuse the feature layer of multi-source signals, and the minimum quantization error (MQE), that is, the distance between the input data and the normal state data, is used as the comprehensive feature quantity of the monitoring state of the equipment, which can be expressed by the following formula:

[0064] MQE(t)=||D(t)-m BMU ||

[0065] Among them, D(t) is the multi-source signal feature vector at time t, and it is used as the input of the neural network; m BMU Represents the wei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com