Efficient oil-water separating device

An oil-water separation device and high-efficiency technology, applied in the field of high-efficiency oil-water separation devices, can solve the problems of low separation efficiency, poor separation effect, poor oil-water separation effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

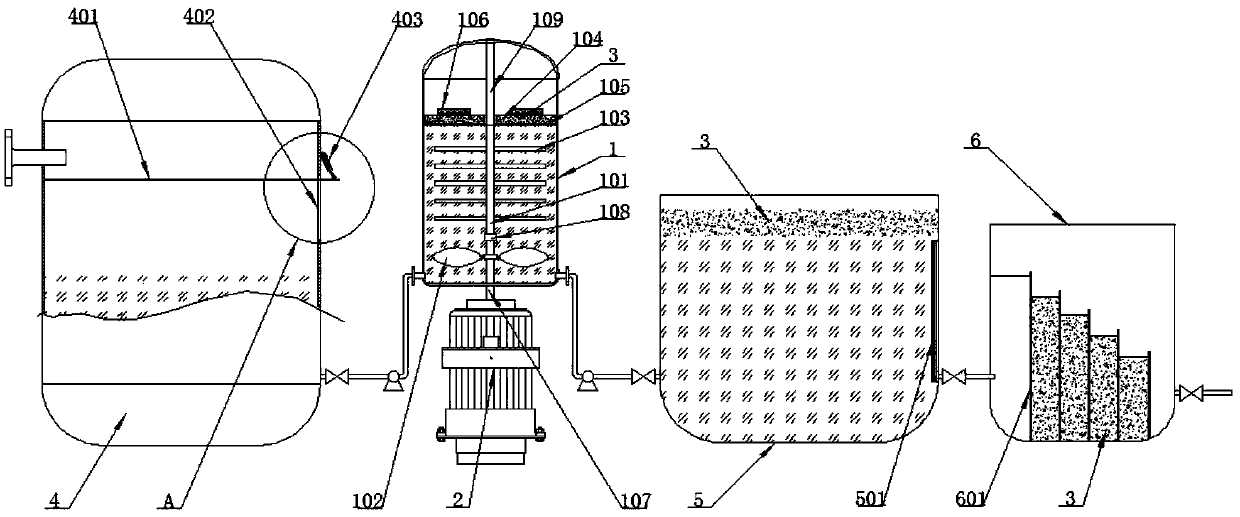

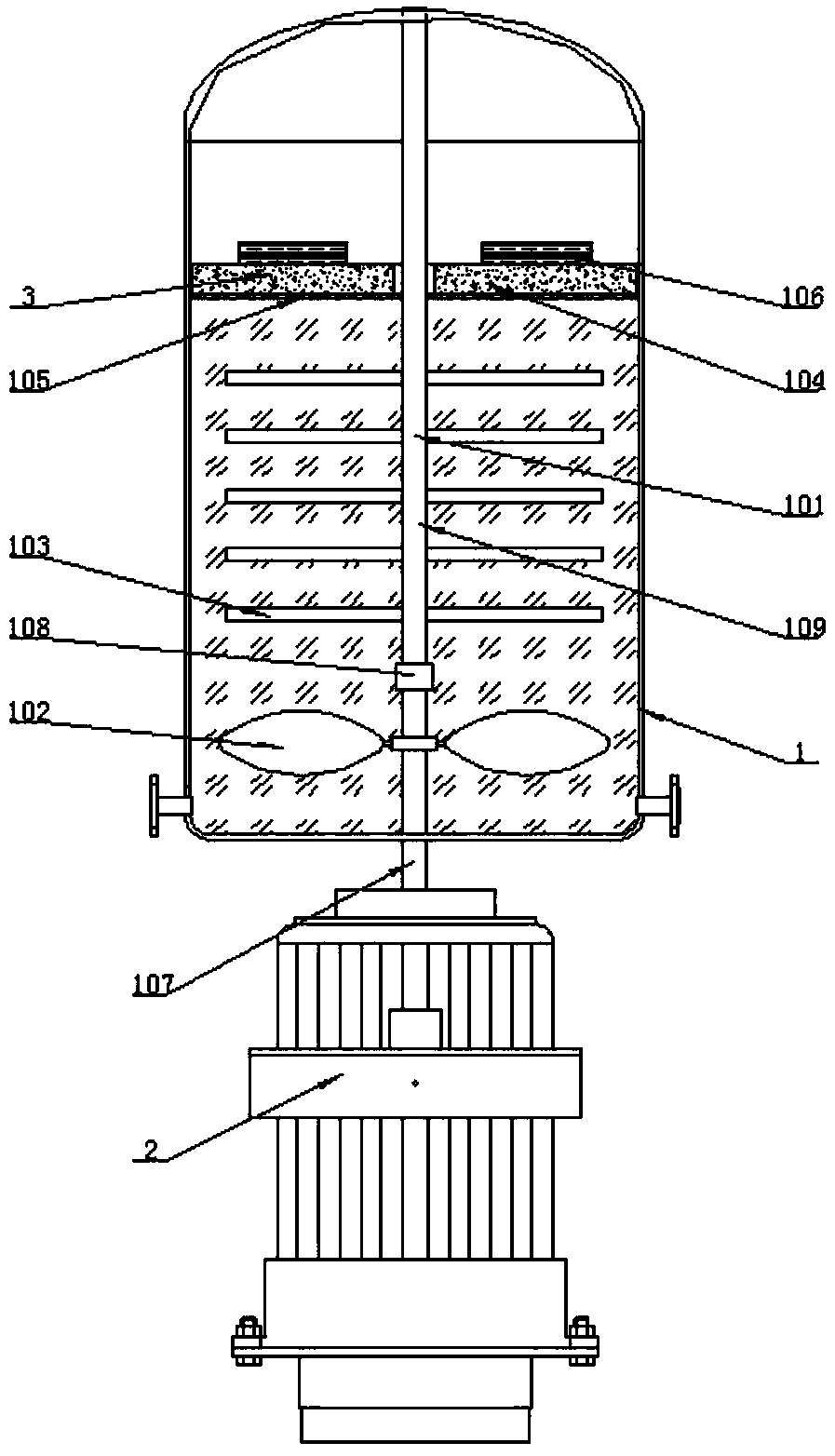

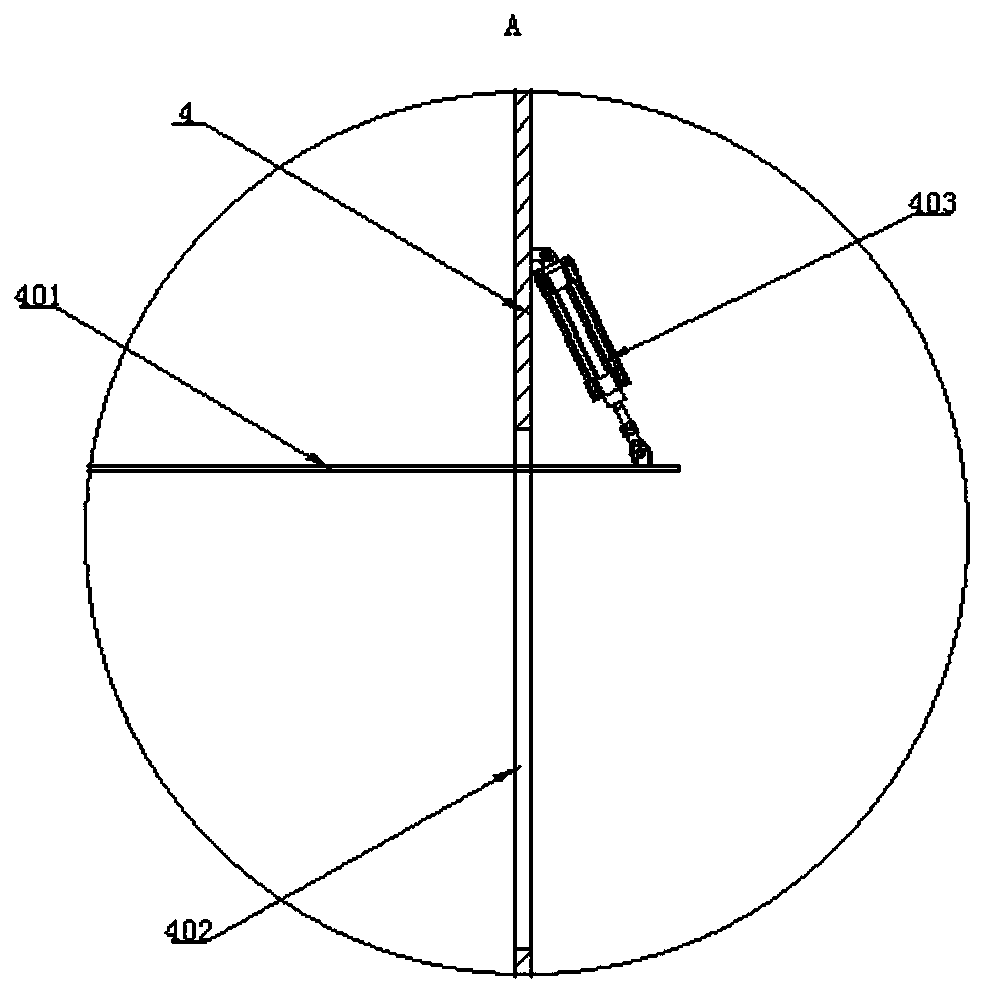

[0016] like Figure 1-3 As mentioned above, it is a high-efficiency oil-water separation device, which includes an upright cylinder 1 for carrying the oil-water mixture. The upright cylinder 1 is inserted with a central shaft 101 coaxial with the upright cylinder 1, and one end of the central shaft 101 extends to Outside the bottom of the upright cylinder 1, the other end extends to the outside of the top of the upright cylinder 1. A drive motor 2 is provided at the bottom of the upright cylinder 1. The drive motor 2 is connected to the corresponding end of the central shaft 101 by transmission. The central shaft 101 is sequentially connected with rotating blades 102, fork-shaped heating rods 103, and an oil suction mechanism 104 from bottom to top. The oil suction mechanism 104 includes a horizontally arranged DC voltage conductive plate 105, and the DC voltage conductive plate 105 is movably socketed on the central shaft 101. Above, the DC voltage conductive plate 105 is cov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com