Network terminal receiver chassis tool

A network terminal and receiver technology, applied in the field of auxiliary equipment, can solve the problems of poor chassis accuracy and low work efficiency, and achieve the effects of less turnover process, improved production efficiency, and less bumps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

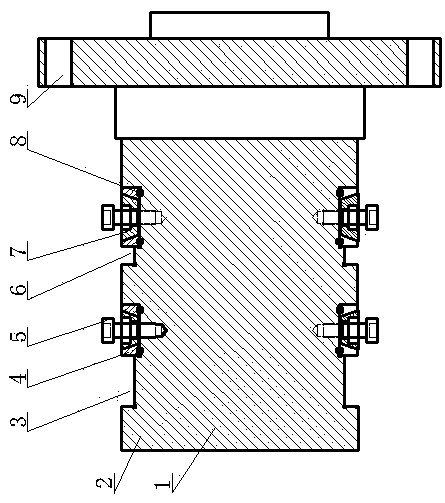

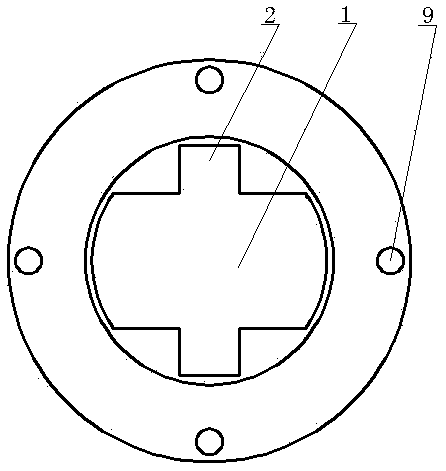

[0010] The present invention will be further described below in conjunction with the accompanying drawings.

[0011] As shown in the figure, an axial convex ridge 2 is left on the columnar tooling body 1, and a longitudinal station groove 3 and a transverse station groove 6 are opened on the convex ridge 2, and the longitudinal station groove 3 and the transverse station groove 6 One end is equipped with a square wedge block 4, and a trapezoidal wedge block 7 is installed in the middle of the wedge block 4. The wedge block 7 is radially connected with the convex ridge by the fastening bolt 5, and the wedge block Positioning pin 8 is housed between the inner surface of 4 and the bottom surface of longitudinal station groove 3, transverse station groove 6; The root of frock body 1 leaves connecting bolt hole 9.

[0012] When working, first install the tooling body 1 on the machine tool through the connecting bolt hole 9, then put the two workpiece blanks into the longitudinal st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com