Cutting device for packing paperboard processing

A cutting device and packaging cardboard technology, which is applied in packaging, metal processing, transportation and packaging, etc., can solve the problems of low cutting efficiency, low work efficiency, low degree of automation, etc., achieve high cutting efficiency, ensure cutting quality, and ensure stability cutting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

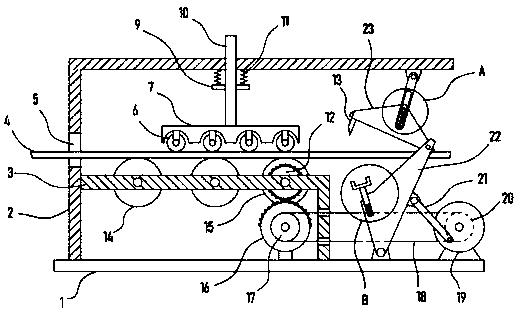

[0022] see Figure 1-4 , a cutting device for packaging cardboard processing, comprising a base plate 1, a support frame 2 is fixedly installed on the base plate 1, an L-shaped support plate 3 is fixedly installed in the support frame 2, and the side wall of the support frame 2 is provided with a paper inlet 5, L On the support plate 3, the rotating type is provided with a guide roller 14 and a driving roller 15, and the guide roller 14 and the driving roller 15 are provided with a cardboard 4 passing through the paper inlet 5. Before cutting the cardboard 4, the cardboard 4 is placed on the guide roller 14 and the driving roller 15 through the paper inlet 5, and the tops of the guide roller 14 and the driving roller 15 are flush.

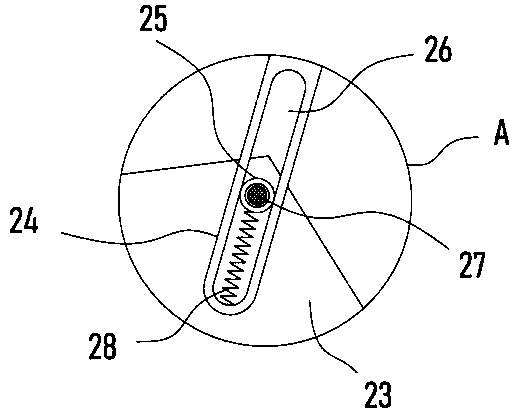

[0023] The bottom plate 1 is rotatably provided with a runner 19, and the runner 19 is connected to the motor, and the drive shaft of the motor is coaxially fixed with the runner 19. The bottom plate 1 is hinged with a support rotating plate 22, a...

Embodiment 2

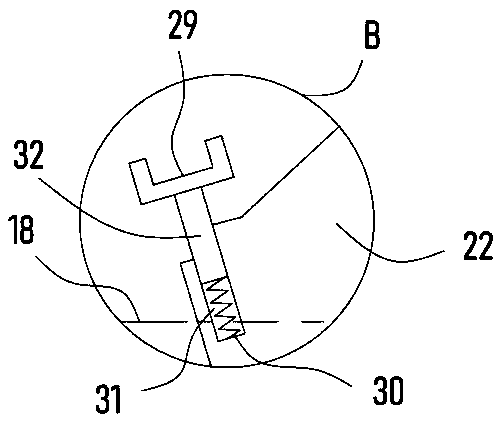

[0030] On the basis of Embodiment 1, in addition, a sliding chamber 31 is opened in the supporting rotating plate 22, and a sliding shaft 32 is slidably installed in the sliding chamber 31, and a damping spring whose upper end is fixedly connected with the sliding shaft 32 is fixedly installed in the sliding chamber 31. 30, the upper end of the sliding shaft 32 is fixedly installed with a support block 29 corresponding to the blade 13, and the support block 29 is a U-shaped structure.

[0031] During the swinging process of the supporting rotating plate 22 and the cutting rotating plate 23, when the blade 13 moves downward, the supporting block 29 moves upward to support the cardboard 4, and the damping spring 30 in the sliding chamber 31 deforms and compresses, The sliding shaft 32 slides along the sliding cavity 31, which plays a buffering and shock-absorbing role for the blade 13 in the cutting process of the cardboard 4, and prevents the cardboard 4 from being greatly defor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com