FFS packaging film and preparation method thereof

A packaging film and formula technology, applied in the direction of chemical instruments and methods, other household appliances, household components, etc., can solve the problems of demanding equipment, demanding processing capacity, and easy adhesion, etc., to achieve good surface friction performance and equipment requirements Not harsh, the effect of good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

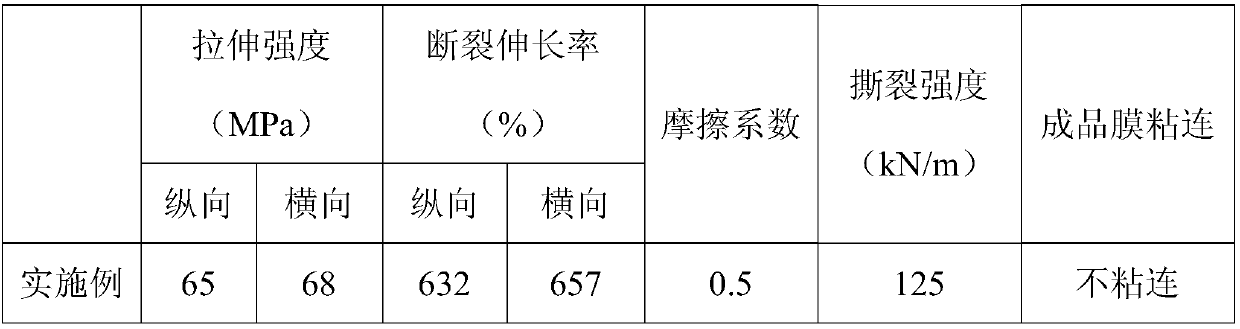

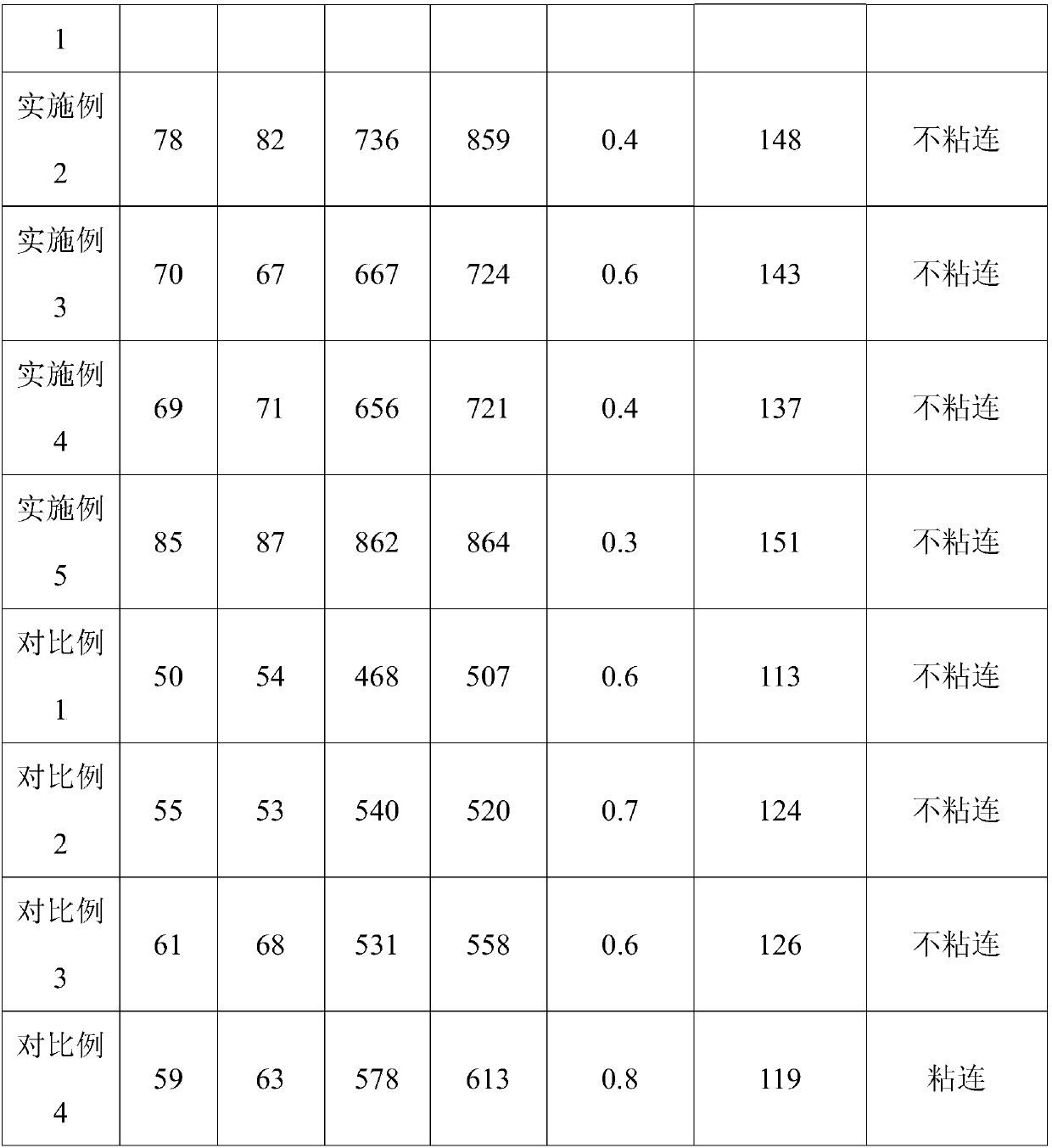

Examples

Embodiment 1

[0039] A kind of FFS packaging film of the present embodiment, described FFS packaging film comprises outer layer, middle layer, inner layer three parts that are arranged sequentially from outside to inside, and the weight ratio of described outer layer, middle layer, inner layer is 1:2: 1, wherein, in parts by weight,

[0040] The outer layer comprises 33 parts of LDPE 2420H and 67 parts of LLDPE LL0220AA;

[0041] The middle layer comprises 37 parts of LDPE 2426H and 67 parts of LLDPE LL0220AA;

[0042] The inner layer comprises 33 parts of LDPE 2426H, 67 parts of LLDPE 1002BU, 1.2 parts of anti-blocking agent 10063 and 1.2 parts of smooth masterbatch.

[0043] The preparation method of the FFS packaging film of the present embodiment comprises the following steps:

[0044] 1) Mixing: mix the raw materials for the preparation of the outer layer in the above formula and transport them to the extruder for mixing to obtain the raw material mixture for the outer layer; mix the...

Embodiment 2

[0048] A kind of FFS packaging film of the present embodiment, described FFS packaging film comprises outer layer, middle layer, inner layer three parts that are arranged successively from outside to inside, and the weight ratio of described outer layer, middle layer, inner layer is 2:3: 1, wherein, in parts by weight,

[0049] The outer layer comprises 30 parts of LDPE 2420H and 70 parts of LLDPE LL0220AA;

[0050] The middle layer comprises 30 parts of LDPE 2426H and 70 parts of LLDPE LL0220AA;

[0051] The inner layer comprises 30 parts of LDPE 2426H, 65 parts of LLDPE 1002BU, 1.5 parts of anti-blocking agent 10063 and 2 parts of smooth masterbatch.

[0052] The preparation method of the FFS packaging film of this embodiment is the same as that of Embodiment 1, and will not be repeated here.

Embodiment 3

[0054] A kind of FFS packaging film of the present embodiment, described FFS packaging film comprises outer layer, middle layer, inner layer three parts that are arranged sequentially from outside to inside, and the weight ratio of described outer layer, middle layer, inner layer is 1:3: 1, wherein, in parts by weight,

[0055] The outer layer comprises 40 parts of LDPE 2420H and 65 parts of LLDPE LL0220AA;

[0056] The middle layer comprises 35 parts of LDPE 2426H and 65 parts of LLDPE LL0220AA;

[0057] The inner layer comprises 40 parts of LDPE 2426H, 62 parts of LLDPE 1002BU, 2 parts of anti-blocking agent 10063 and 1 part of smooth masterbatch.

[0058] The preparation method of the FFS packaging film of this embodiment is the same as that of Embodiment 1, and will not be repeated here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com