Method for maintaining operation stability of aerobic granular sludge (AGS) reactor based on particle size control

A technology of aerobic granular sludge and particle size control, applied in chemical instruments and methods, water treatment parameter control, water/sludge/sewage treatment, etc., can solve the problems of easy instability of the reactor and achieve high reliability , to achieve long-term stability maintenance, easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

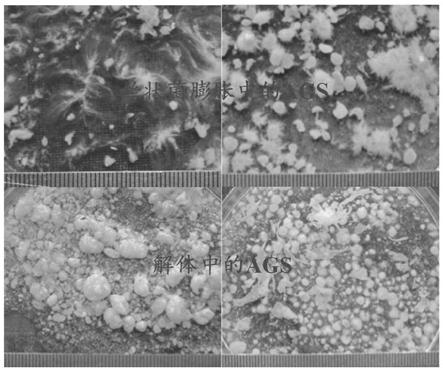

[0015] A method for maintaining the operation stability of an aerobic granular sludge reactor based on particle size control, the method steps are as follows:

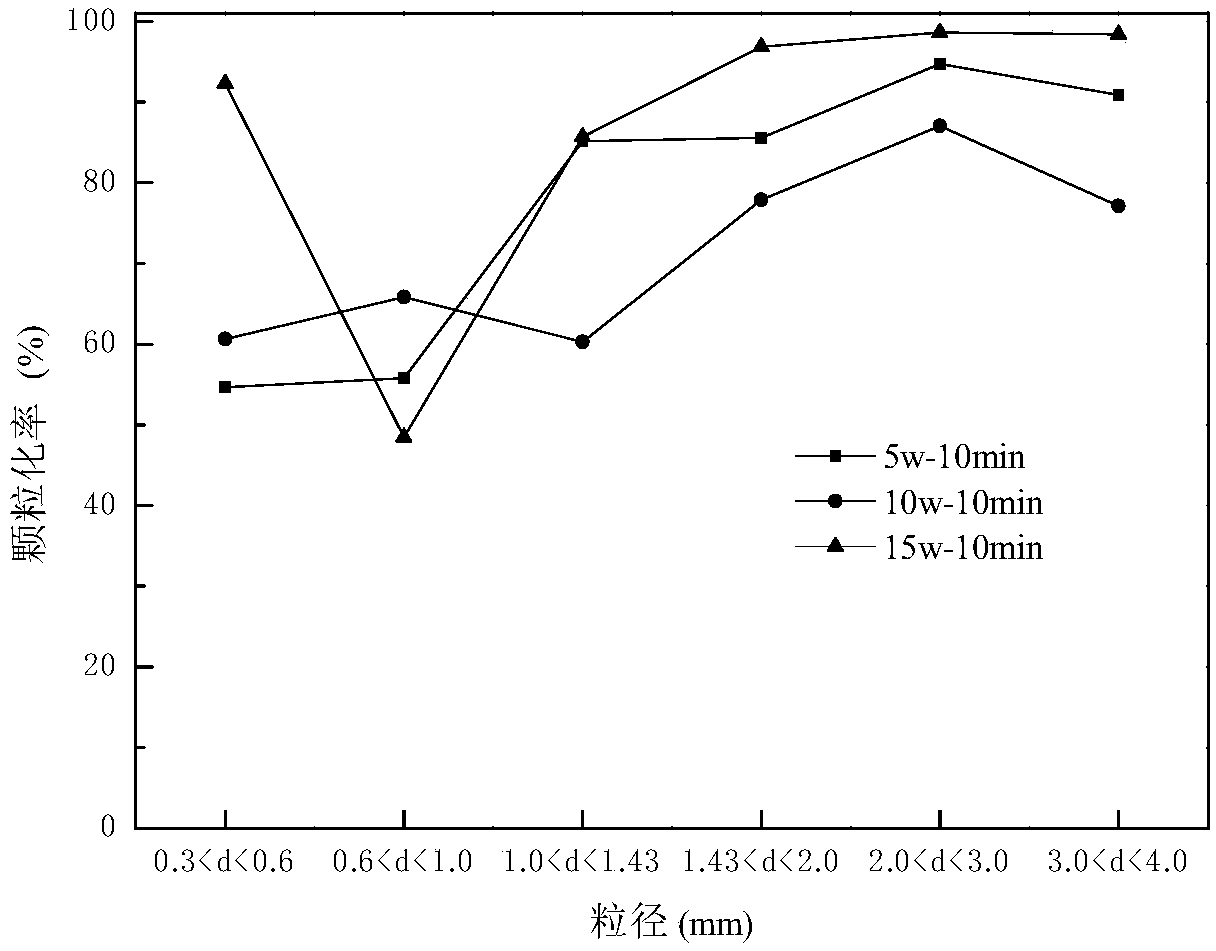

[0016] (1) Measure the granulation rate of the sludge in the reactor. When the granulation rate is above 80%, it is considered that aerobic granulation has been successfully achieved. Otherwise, the selective pressure should be continued to increase to promote the granulation of the sludge until the granulation up to over 80%. Then take 100-500mL of the mud-water mixture in the aerated state of the aerobic granular sludge reactor, and then sieve through standard sieves from large to small apertures to obtain aerobic granular sludge with different particle size ranges, and collect these The aerobic granular sludge with different particle size ranges was fixed to the same volume. The pore size of the standard sieve is 4mm, 3mm, 2mm, 1.43mm, 1mm, 0.6mm and 0.3mm from large to small; the particle size of aerobic granular ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com