Graphene/chlorinated polypropylene modified melamine foam oil-absorbing material and preparation method thereof

A technology of chlorinated polypropylene and melamine, applied in chemical instruments and methods, separation methods, liquid separation, etc., to achieve the effects of improved hydrophobicity, larger elongation at break, and improved tensile capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Dissolve chlorinated polypropylene in toluene at room temperature to prepare a solution of a certain concentration, then add a certain amount of graphene nanosheets to it, and disperse with ultrasonic waves for 30 minutes to obtain a stably dispersed graphene / chlorinated polypropylene dispersion. Then immerse the melamine foam into the graphene / chlorinated polypropylene dispersion liquid, ultrasonically disperse it for 30 minutes, take out the melamine foam, and dry it to a constant weight to obtain a modified melamine foam oil-absorbing material. The chlorinated polypropylene accounted for 1% by mass of toluene; the mass fraction of graphene nanosheets accounted for toluene was 0.5%.

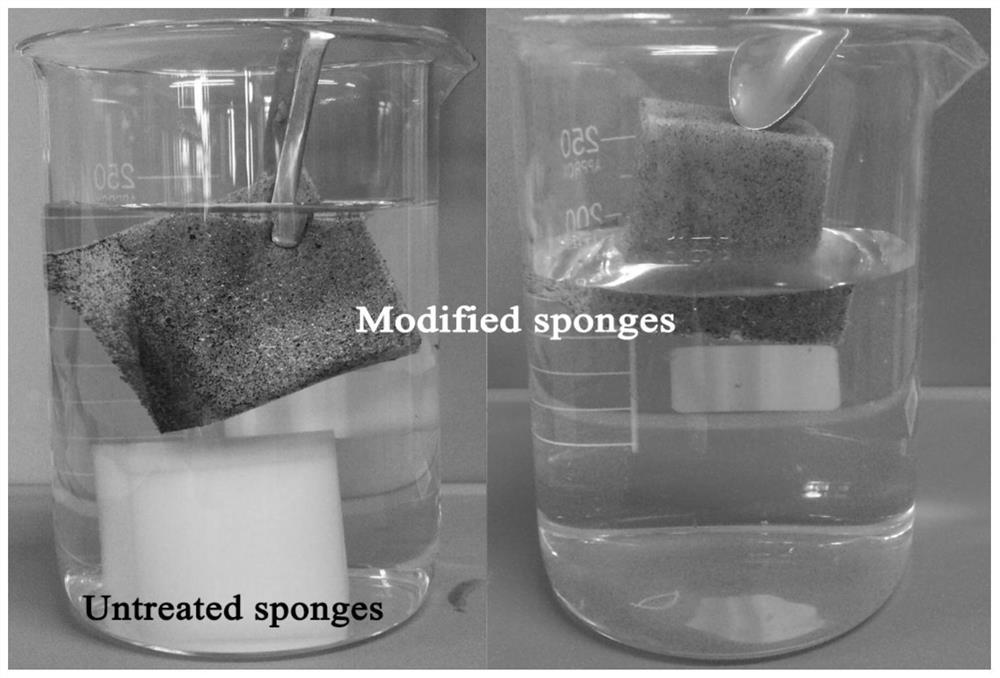

[0025] figure 1 It can be seen that the melamine foam sinks to the bottom of the water, and the modified melamine foam oil-absorbing material obtained in Example 1 floats on the water surface. When the modified melamine foam oil-absorbing material is pressed into the water, there is a ph...

Embodiment 2

[0027] Dissolve chlorinated polypropylene in toluene at room temperature to prepare a solution of a certain concentration, then add a certain amount of graphene nanosheets to it, and disperse with ultrasonic waves for 30 minutes to obtain a stably dispersed graphene / chlorinated polypropylene dispersion. The melamine foam was immersed in the graphene / chlorinated polypropylene dispersion liquid, and after ultrasonic dispersion for 30 minutes, the melamine foam was taken out, the solvent was removed, and dried to constant weight to obtain the modified melamine foam oil-absorbing material. Chlorinated polypropylene accounted for 1% by mass of toluene. The mass fraction of graphene nanosheets in toluene is 0.1%.

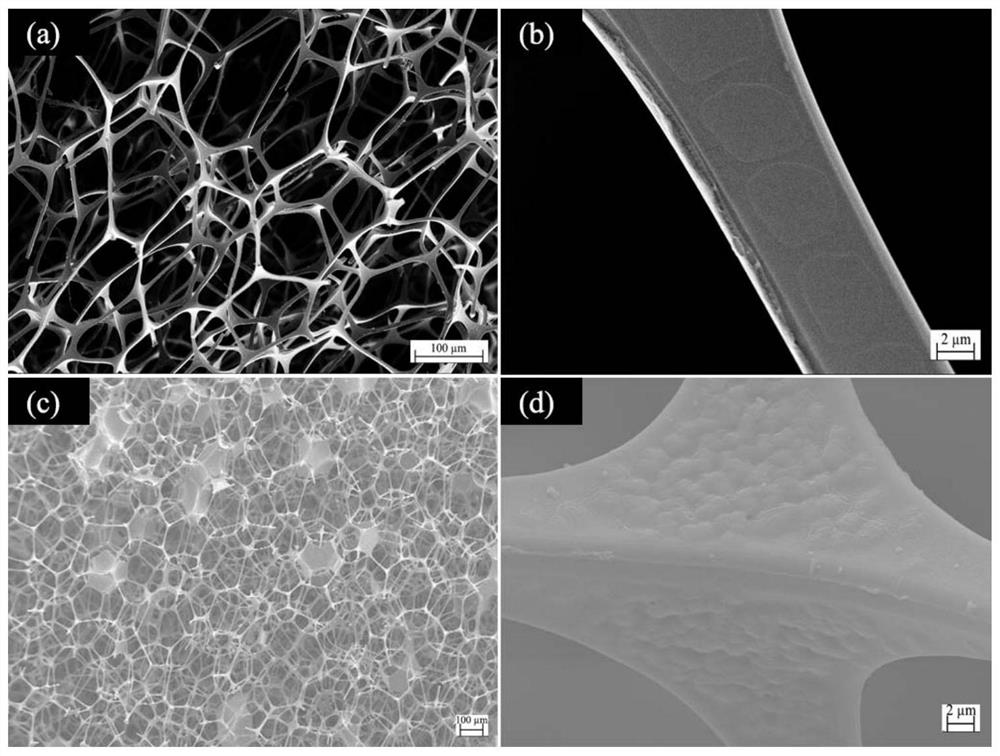

[0028] figure 2 The scanning electron micrograph of the surface of the modified melamine foam oil-absorbing material prepared in Example 2. It can be seen from (a) (b) that the unmodified melamine foam oil-absorbing material has a three-dimensional network structure. ...

Embodiment 3

[0030] Dissolve chlorinated polypropylene in toluene at room temperature to prepare a solution of a certain concentration, then add a certain amount of graphene nanosheets to it, and disperse with ultrasonic waves for 30 minutes to obtain a stably dispersed graphene / chlorinated polypropylene dispersion. The melamine foam was immersed in the graphene / chlorinated polypropylene dispersion liquid, and after ultrasonic dispersion for 30 minutes, the melamine foam was taken out, the solvent was removed, and dried to constant weight to obtain the modified melamine foam oil-absorbing material. The chlorinated polypropylene accounted for 2% by mass of toluene; the mass fraction of graphene nanosheets accounted for toluene was 0.1%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| water contact angle | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com