A scroll tooth structure of an oil-free scroll compressor

A scroll compressor and scroll technology, which is applied in the field of scroll compressors, can solve problems such as inability to seal axial gaps in a targeted manner, and achieve the effects of saving raw materials and improving sealing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

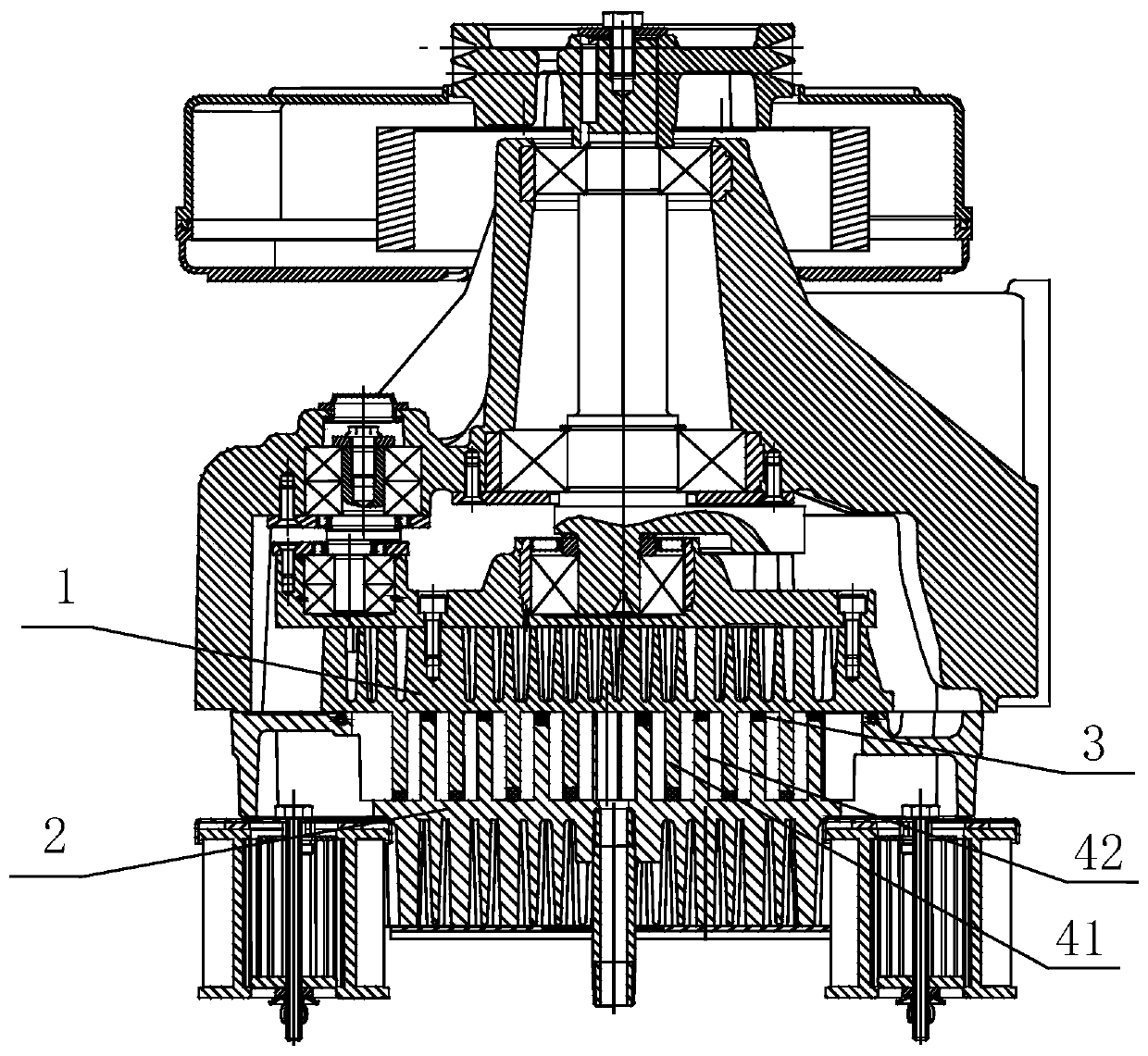

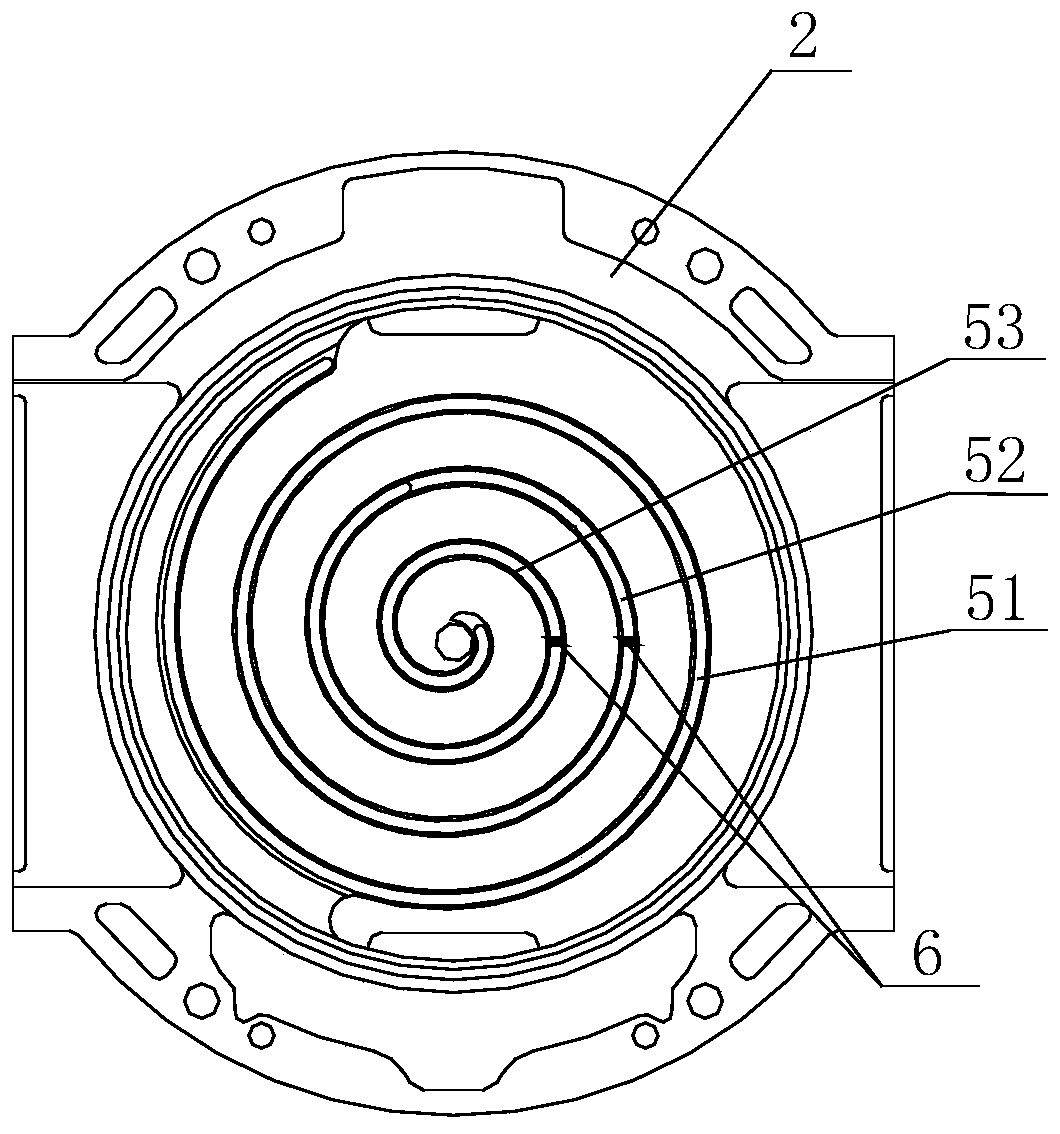

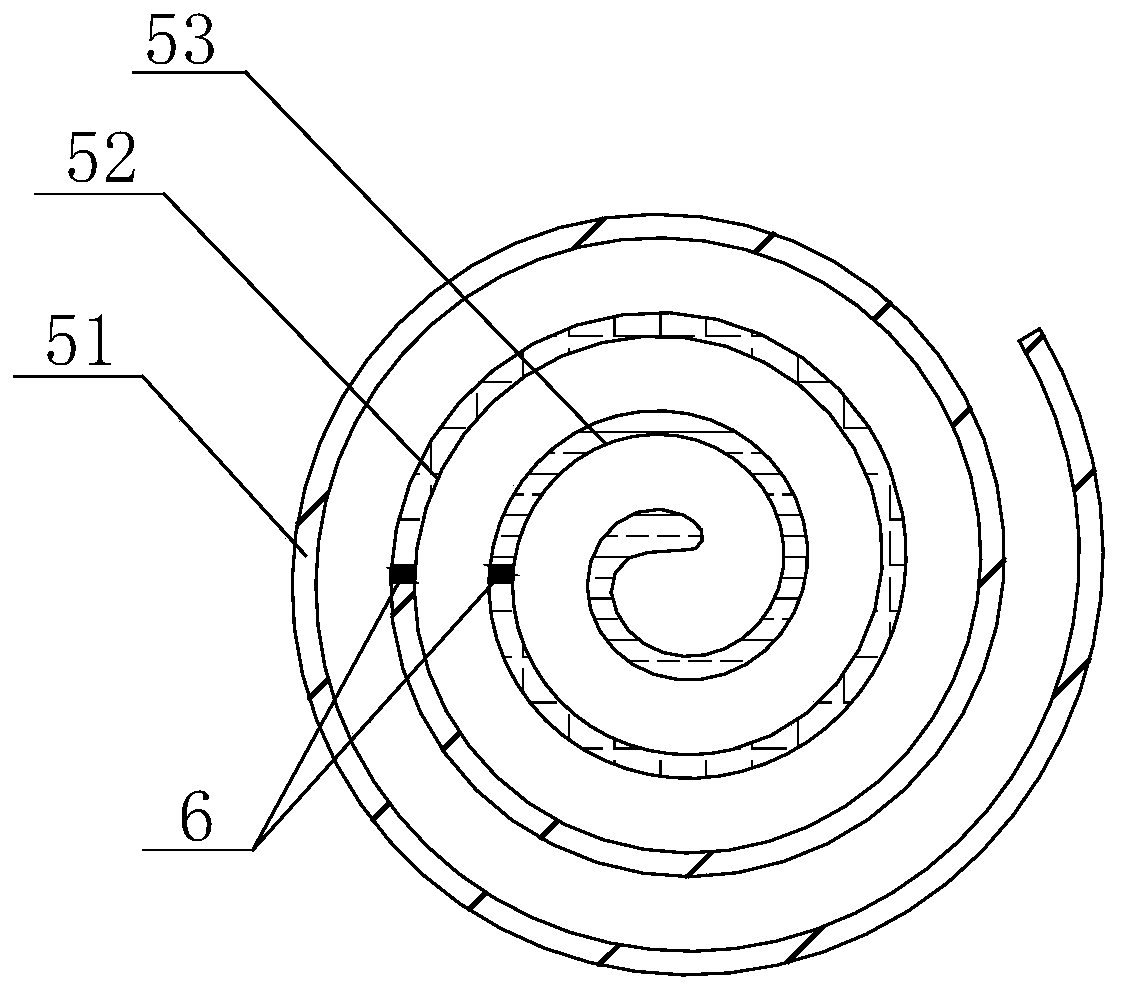

[0048] Such as figure 1 , 2 As shown in . Scroll teeth 42. Both the ends of the first spiral teeth 41 and the second spiral teeth 42 are provided with tooth grooves, and the sealing strips 3 are fixed inside the tooth grooves. Because the first spiral teeth 41 and the second spiral teeth 42 are symmetrically distributed, and the structures and materials are exactly the same, so the following uses the first spiral teeth 41 as an example, but actually both refer to the first spiral teeth 41 and the first spiral teeth. Spiral tooth 42.

[0049] According to the magnitude of the pressure it is subjected to, the first scroll 41 is divided into three areas inwardly from its outermost end (that is, the suction end of the oil-free scroll compressor): a low-pressure area 51, a medium-pressure area, zone 52 and high pressure zone 53. The specific division method is: taking the length of the first spiral tooth 41 as the total length, extending inward from the outermost end / outermost...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com