Wedge-shaped power-enhanced wire control brake

A brake-by-wire and booster technology, which is applied in the types of brakes, axial brakes, brake actuators, etc., can solve the difficult contradiction between motor torque and structural size, restrict market promotion and application, and require extremely high motor performance, etc. problems, to achieve rapid response to braking commands, improve braking safety, and shorten the braking distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

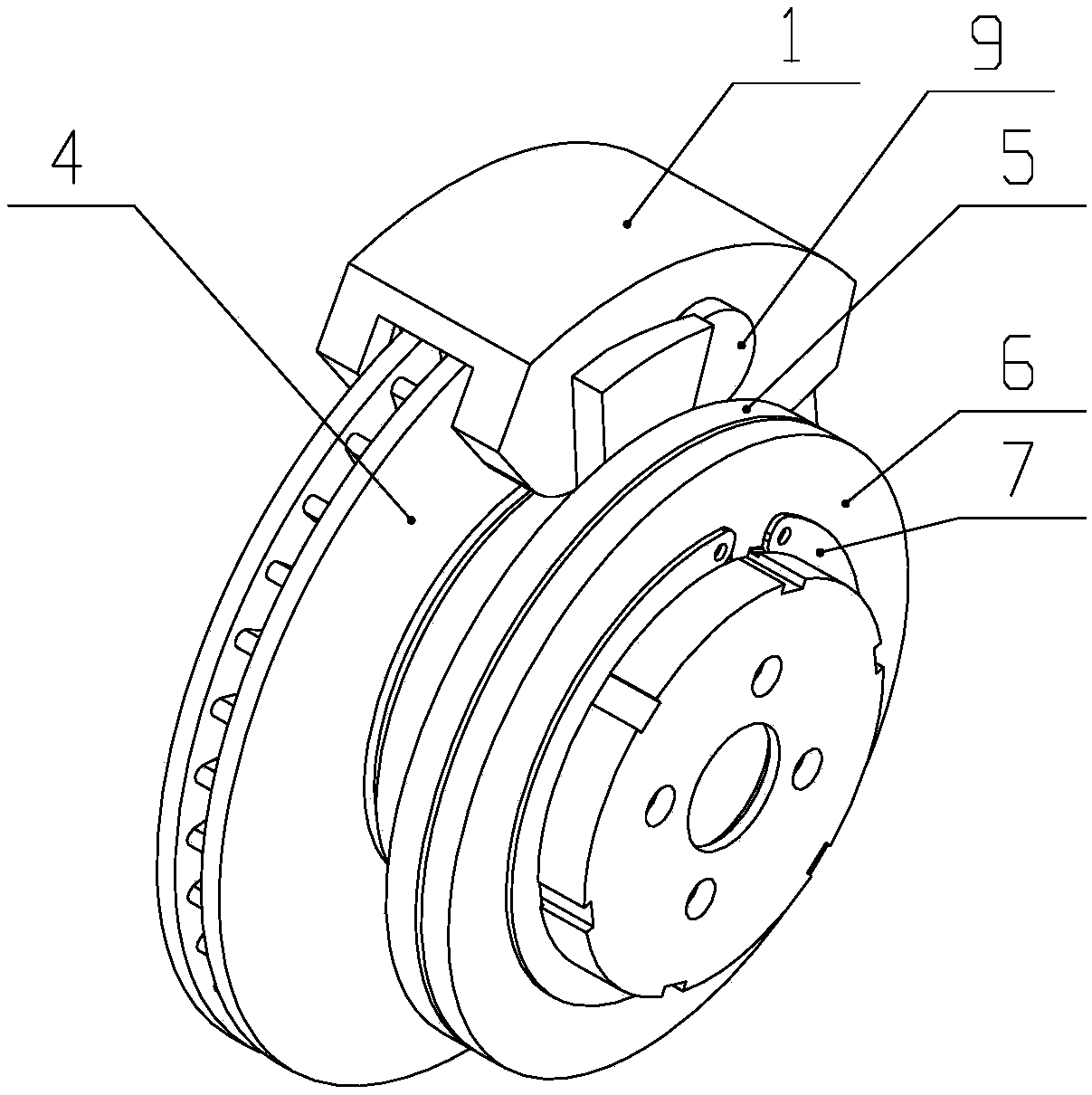

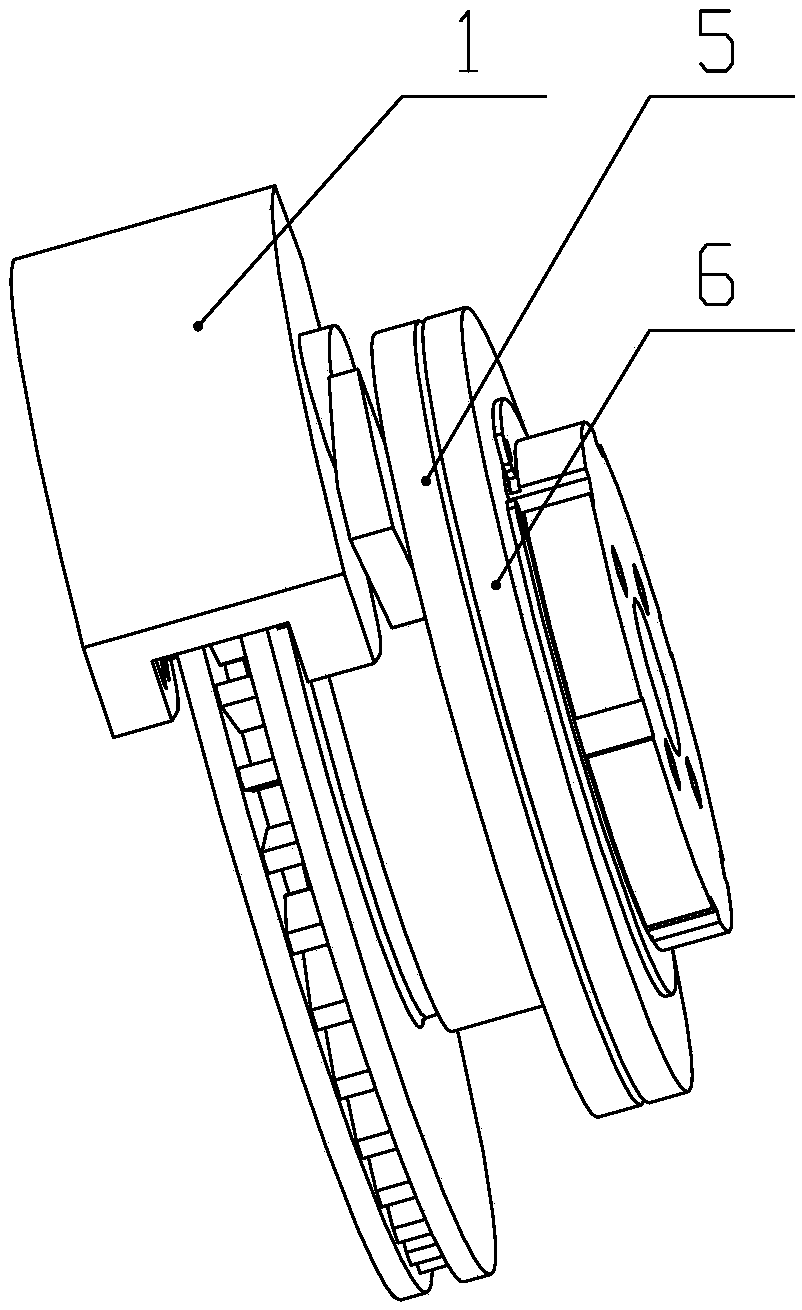

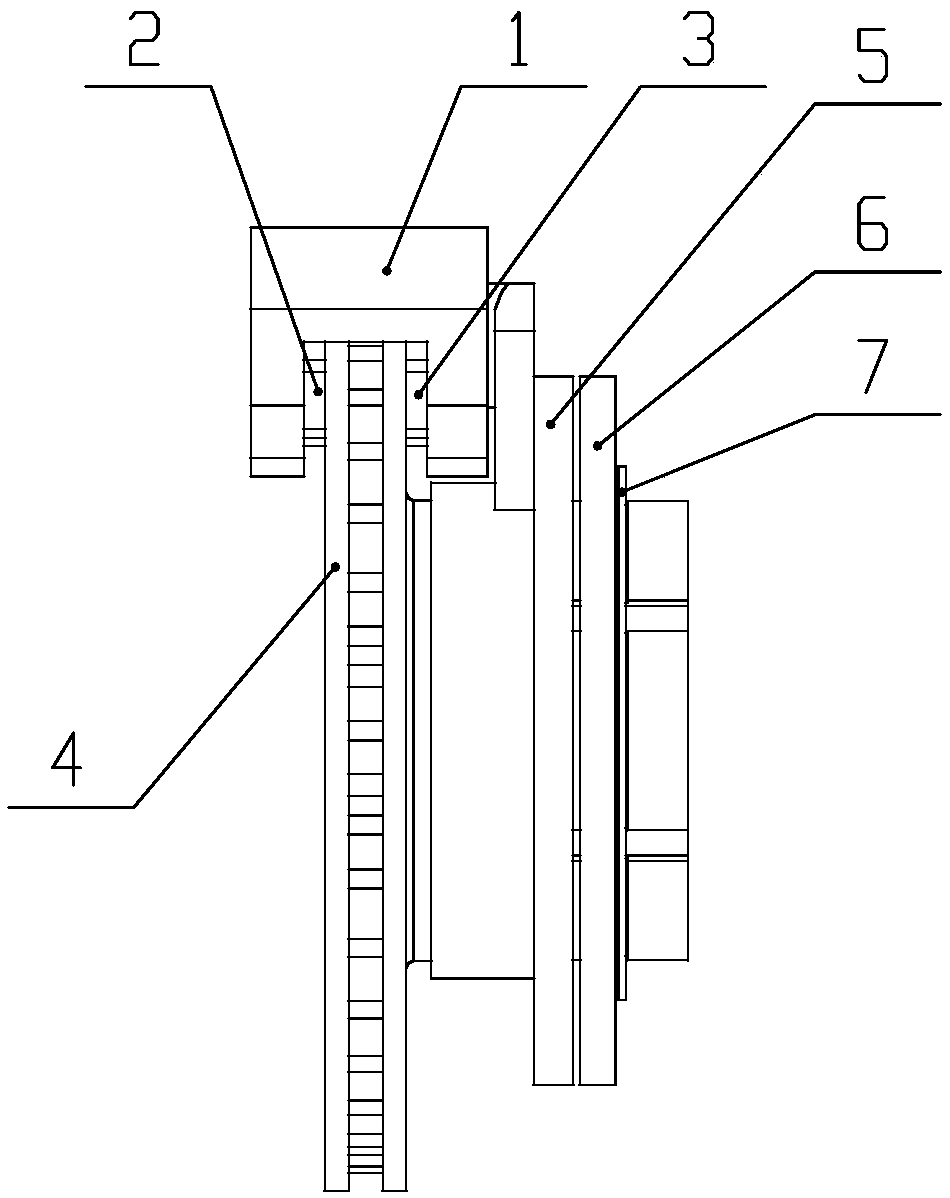

[0041] In order to clearly illustrate the technical features of the solution, the solution will be described below through a specific implementation mode and in conjunction with the accompanying drawings.

[0042] A wedge-shaped booster brake by wire, comprising a caliper 1, a left friction plate 2, a right friction plate 3, a brake disc 4, a driven electromagnet 5, an active electromagnet 6, a retaining ring 7, a return spring assembly 8, Piston 9, brake pedal sensor 10, wheel speed sensor 11, controller 12; the described caliper 1 is installed on the vehicle frame, and the left friction plate 2 and the right friction plate 3 are respectively installed in the corresponding slots on the caliper 1 In the mouth, to limit the rotation; the brake disc 4 is installed between the left friction plate 2 and the right friction plate 3, and the braking gap between the brake disc 4 and the left friction plate 2 and the right friction plate 3 is 0.1mm~ 1mm; the piston 9 is installed in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com